Operating instrutions

WITA Fixed Setpoint Controller SM WR FR

Table of Contents

Declaration of conformity ........................................................................................................

Safety instructions.....................................................................................................................

General........................................................................................................................................................

Instructions of symbols in the operating instructions...................................................................

Personnel qualification...........................................................................................................................

Dangers of not observance of the safety instructions..................................................................

Safety conscious working......................................................................................................................

Safety instructions for the operator...................................................................................................

Safety instructions for installation and maintenance....................................................................

Unauthorized conversion and spare parts production .................................................................

Unpermitted operation ..........................................................................................................................

Transport and storage ............................................................................................................

Intended Use ..............................................................................................................................

Technical data for the WITA fixed value controller..............................................................

Dimensions ..............................................................................................................................................

Technical specifications .........................................................................................................................

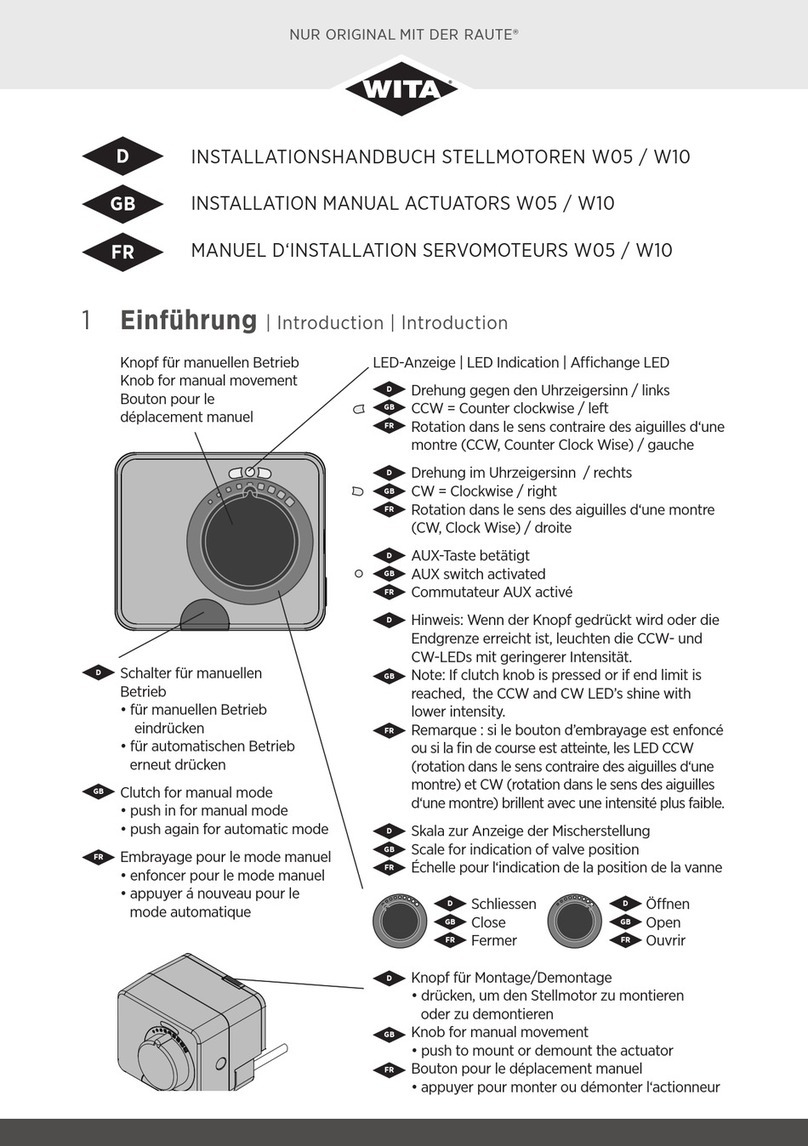

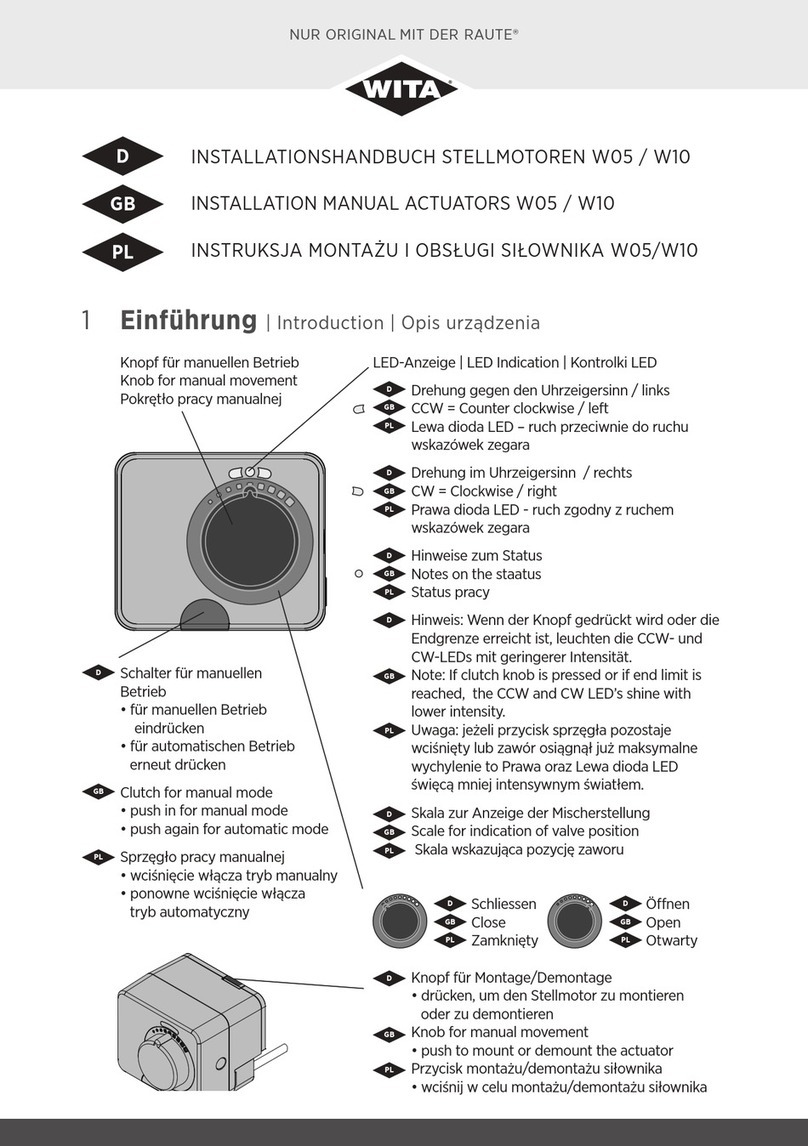

Operating elements of the fixed value controller SM WR FR.....................................................

Graphic Display ........................................................................................................................................

User guide..................................................................................................................................................

Ads in case of failure...............................................................................................................................

Manual mode.............................................................................................................................................

Assembly of the controller SM WR FR on heating mixer.....................................................

Mounting of the fixed setpoint controller SM WR FR onto dierent mixing valves ............

Electrical installation...............................................................................................................................

Safety instructions before and for commissioning ...............................................................

For visible damage..................................................................................................................................

Selection and setting of the applications setting temperature and mixer (valve)

direction of rotation................................................................................................................................

- Selection of application heating .....................................................................................................

- Selection and adjustment of the set point temperature ..............................................................

- Selection and adjustment of the mixer (valve) direction of rotation .......................................

Selection of hydraulic scheme and setting the minimum setpoint and maximum

temperature...............................................................................................................................................

- Selection of hydraulic scheme .............................................................................................................

- Selection and adjustment of the minimum maximum and setpoint temperature

for the heating application....................................................................................................................

- Selection and setting of the minimum maximum and setpoint temperature during

application cooling ..................................................................................................................................

Commissioning of the WITA fixed setpoint controller SM WR FR......................................

Sensor features ..........................................................................................................................

Sensor resistance values........................................................................................................................

20