Witschi Electronic Ltd Analyzer Q1 Page 3

TABLE OF CONTENTS

1GETTING STARTED..................................................................................................................................5

2FIELD OF APPLICATION...........................................................................................................................5

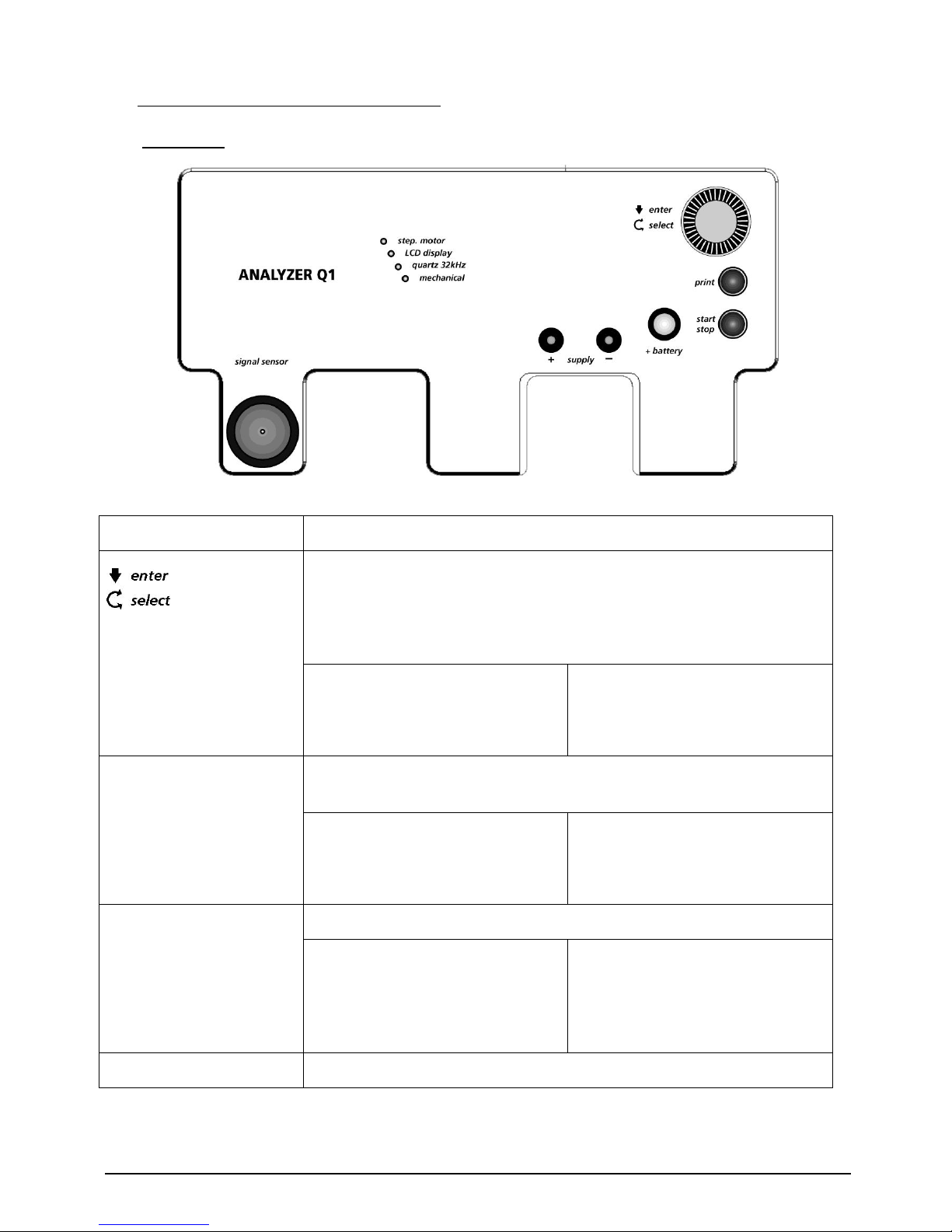

3OPERATING ELEMENTS AND DISPLAYS...................................................................................................6

3.1 Work Area .............................................................................................................................................. 6

3.2 Rear panel .............................................................................................................................................. 7

3.3 Display Panel.......................................................................................................................................... 8

4COMMISSIONING ...................................................................................................................................8

4.1 Extent of Delivery ................................................................................................................................... 8

4.2 Place of Installation................................................................................................................................ 9

4.3 Mains Connection................................................................................................................................... 9

4.4 Printer Connection.................................................................................................................................. 9

4.5 Language................................................................................................................................................ 9

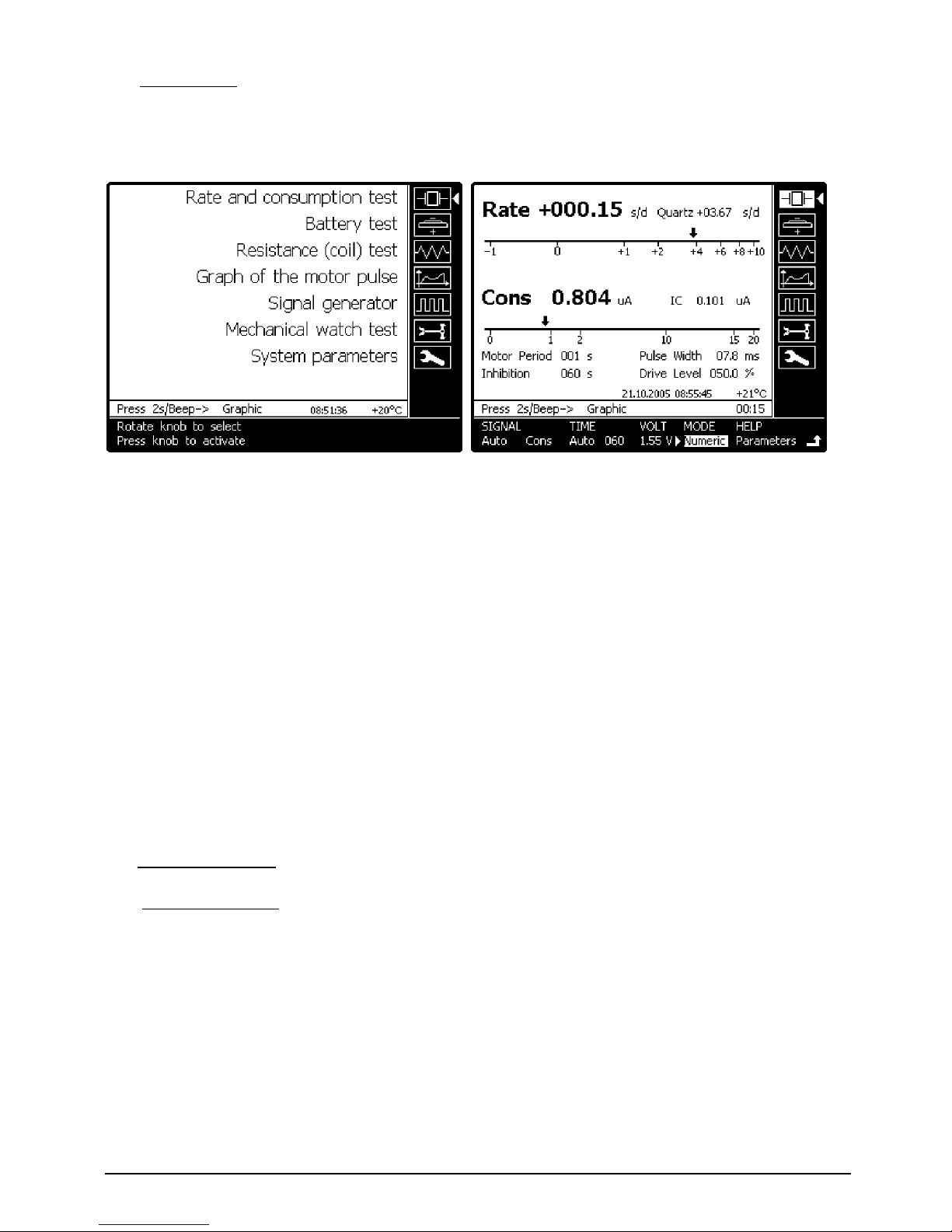

5GENERAL OPERATION ..........................................................................................................................10

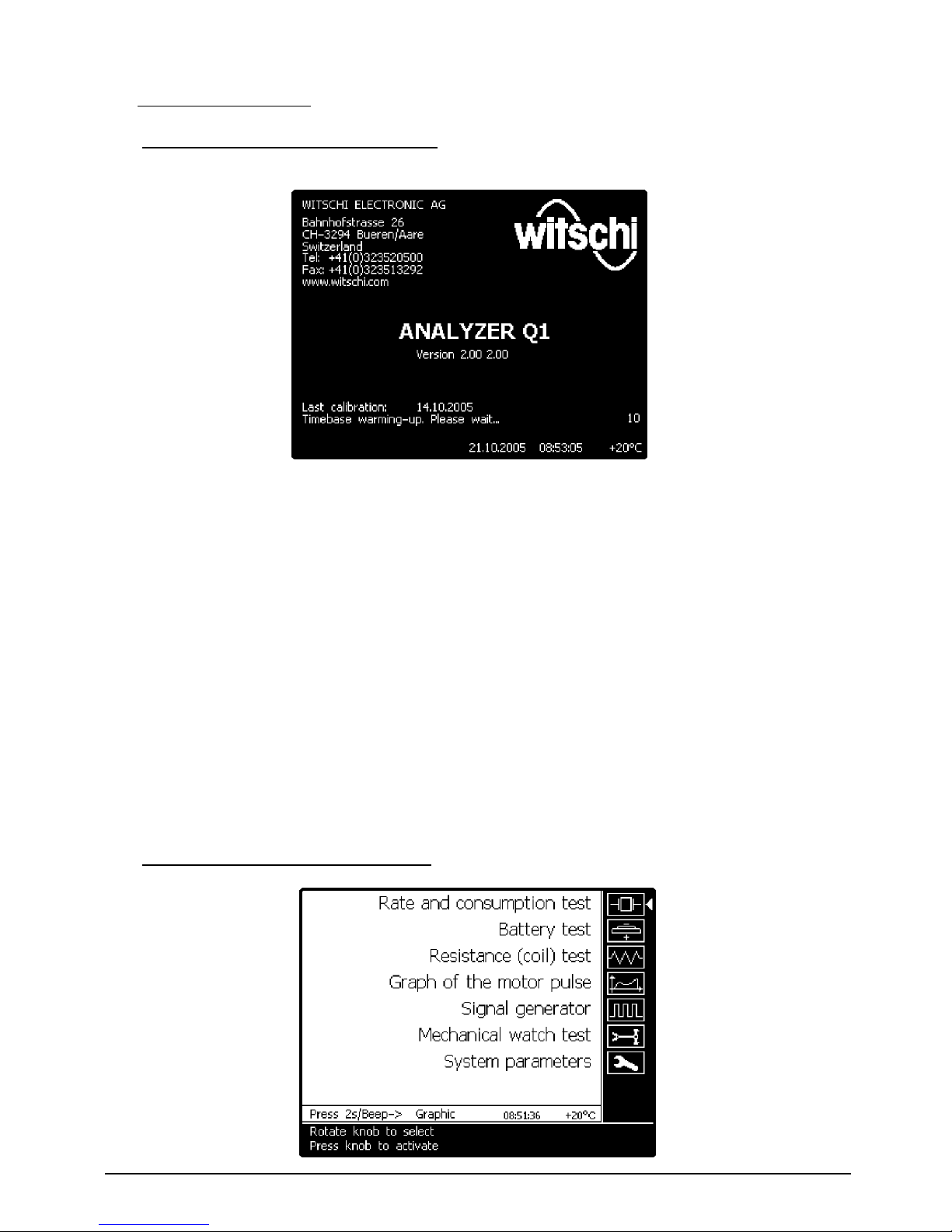

5.1 Switching the Analyzer Q1 On and Off................................................................................................. 10

5.2 Selection of a Measurement Function .................................................................................................. 10

5.3 Parameter Settings ............................................................................................................................... 11

5.4 Help...................................................................................................................................................... 12

6RATE MEASUREMENT OF QUARTZ WATCHES .......................................................................................13

6.1 General Introduction ............................................................................................................................ 13

6.2 Measurement Sequence ....................................................................................................................... 13

6.3 Result Display....................................................................................................................................... 14

7PULSE PARAMETERS.............................................................................................................................15

7.1 General Introduction ............................................................................................................................ 15

7.2 Result Display....................................................................................................................................... 15

8LONG-TIME RECORDING (TRACE MODE) ..............................................................................................15

8.1 Result Display....................................................................................................................................... 15

9MODULE SUPPLY AND CURRENT MEASUREMENT.................................................................................16

9.1 Connecting the Watch .......................................................................................................................... 16

9.2 Current Measurement........................................................................................................................... 17

9.3 Minimum Operating Voltage................................................................................................................ 18

9.4 Watch Acceleration .............................................................................................................................. 19

10 BATTERY TESTING ................................................................................................................................19

10.1 Connecting Points ................................................................................................................................ 19

10.2 Test Sequence....................................................................................................................................... 19

10.3 Result Display....................................................................................................................................... 20

11 GRAPH OF THE MOTOR PULSE..............................................................................................................20

11.1 General Introduction ............................................................................................................................ 20

11.2 Procedure ............................................................................................................................................. 20

11.3 Result Display....................................................................................................................................... 21

12 TEST OF COIL RESISTANCE AND COIL INSULATION ...............................................................................21

12.1 General Introduction ............................................................................................................................ 21

12.2 Procedure ............................................................................................................................................. 21

12.3 Result Display....................................................................................................................................... 22

13 TEST OF STEP MOTORS WITH THE SIGNAL GENERATOR ........................................................................22

13.1 Field of Application .............................................................................................................................. 22

13.2 Procedure ............................................................................................................................................. 22