II

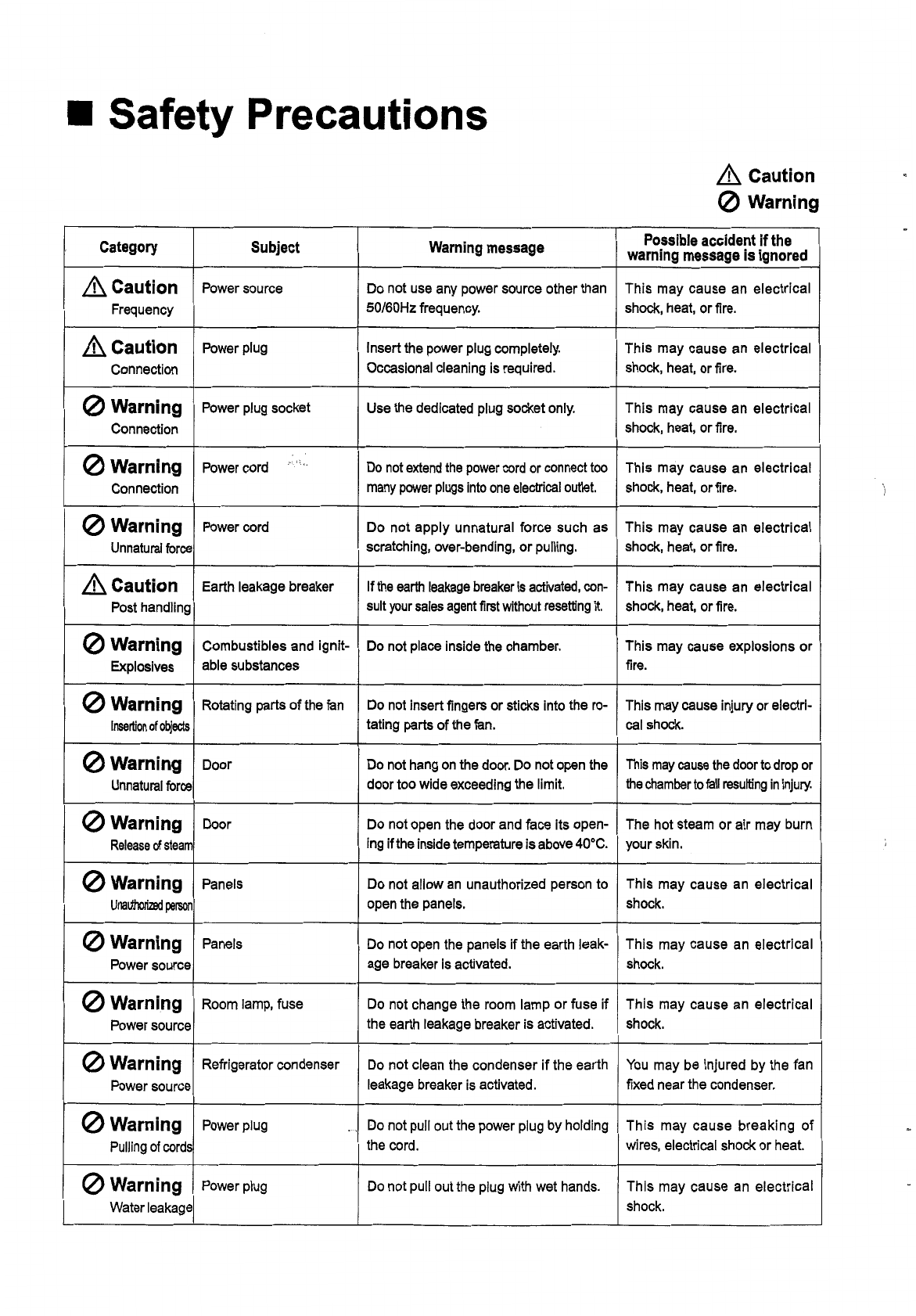

Safety Precautions

&.

Caution

(2)

Warning

Category Subject Warning message Possible accident if the

warning message is ignored

&.

Caution

Power source Do not use any power source other than This may cause an electrical

Frequency SO/60Hzfrequency. shock, heat, or fire.

&.

Caution

Power plug Insert the power plug completely. This may cause an electrical

Connection Occasional cleaning is required. shock, heat, or fire.

(2)

Warning

Power plug socket Use the dedicated plug socket only. This may cause an electrical

Connection shock, heat, or fire.

(2)

Warning

Power cord

,"- ! ~,.

Do notextendthe powercordor connecttoo This may cause an electrical

Connection manypowerplugsintooneelectricaloutlet. shock, heat, or fire.

(2)

Warning

Power cord Do not apply unnatural force such as This may cause an electrical

Unnaturalforce scratching, over-bending, or pulling. shock, heat, or fire.

&'Caution

Earth leakage breaker Ifthe earthleakagebreakeris activated,con- This may cause an electrical

Post handling suityoursalesagentfirstwithoutresetting

It.

shock, heat, or fire.

(2)

Warning

Combustibles and ignit- Do not place inside the chamber. This may cause explosions or

Explosives able substances fire.

(2)

Warning

Rotating parts of the fan Do not insert fingers or sticks into the ro- This may cause injury or electri-

Insertion

of

objects tating parts of the fan. cal shock.

(2)

Warning

Door Do not hang on the door. Do not open the Thismaycausethedoorto dropor

Unnaturalforce door too wide exceeding the limit. thechambertofallresultingininjury.

(2)

Warning

Door Do not open the door and face its open- The hot steam or air may burn

Releaseofsteam ing ifthe inside temperature is above 40·C. your skin.

(2)

Warning

Panels Do not allow an unauthorized person to This may cause an electrical

Unauthorized person

open the panels. shock.

(2)

Warning

Panels Do not open the panels if the earth leak- This may cause an electrical

Power source age breaker is activated. shock.

(2)

Warning

Room lamp, fuse Do not change the room lamp or fuse if This may cause an electrical

Power source the earth leakage breaker is activated. shock.

(2)

Warning

Refrigerator condenser Do not clean the condenser if the earth You may be injured by the fan

Power source leakage breaker is activated. fixed near the condenser.

(2)

Warning

Power plug

,--,

Do not pull out the power plug by holding This may cause breaking of

Pullingof cords the cord. wires, electrical shock or heat.

o

Warning

Power plug Do not pull out the plug with wet hands. This may cause an electrical

Water leakage shock.