should be mounted in the return line between the BDP2 outlet and the DWR.

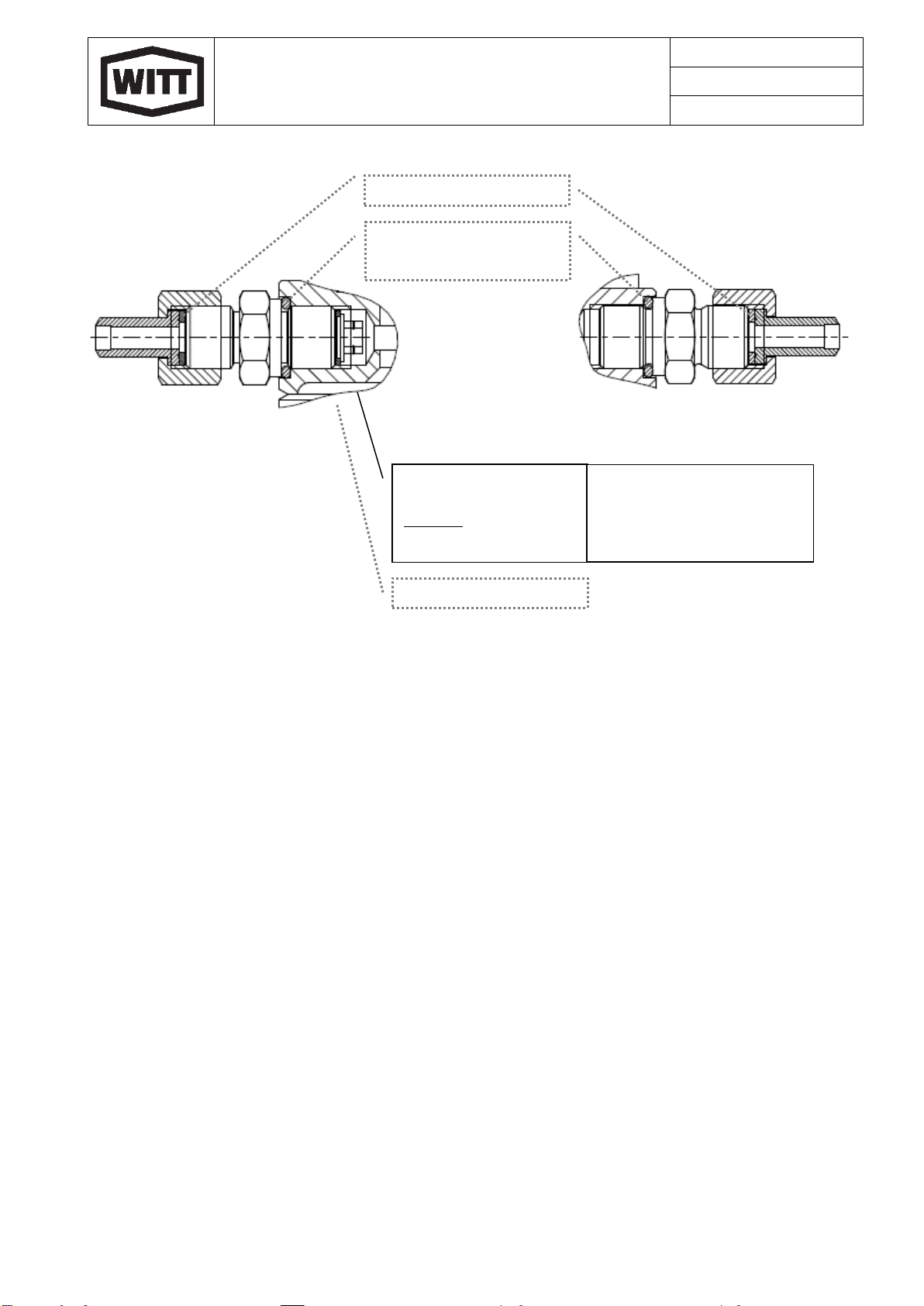

If you do not have hot gas with a differential pressure of at least 4 bar available, you should replace the standard

check valve. This check valve will open with a differential pressure of 1 bar. It needs to be ordered separately and

will be additionally delivered loose. This check valve is marked with a “1” next to the inlet connection.

6.4 Hot gas line

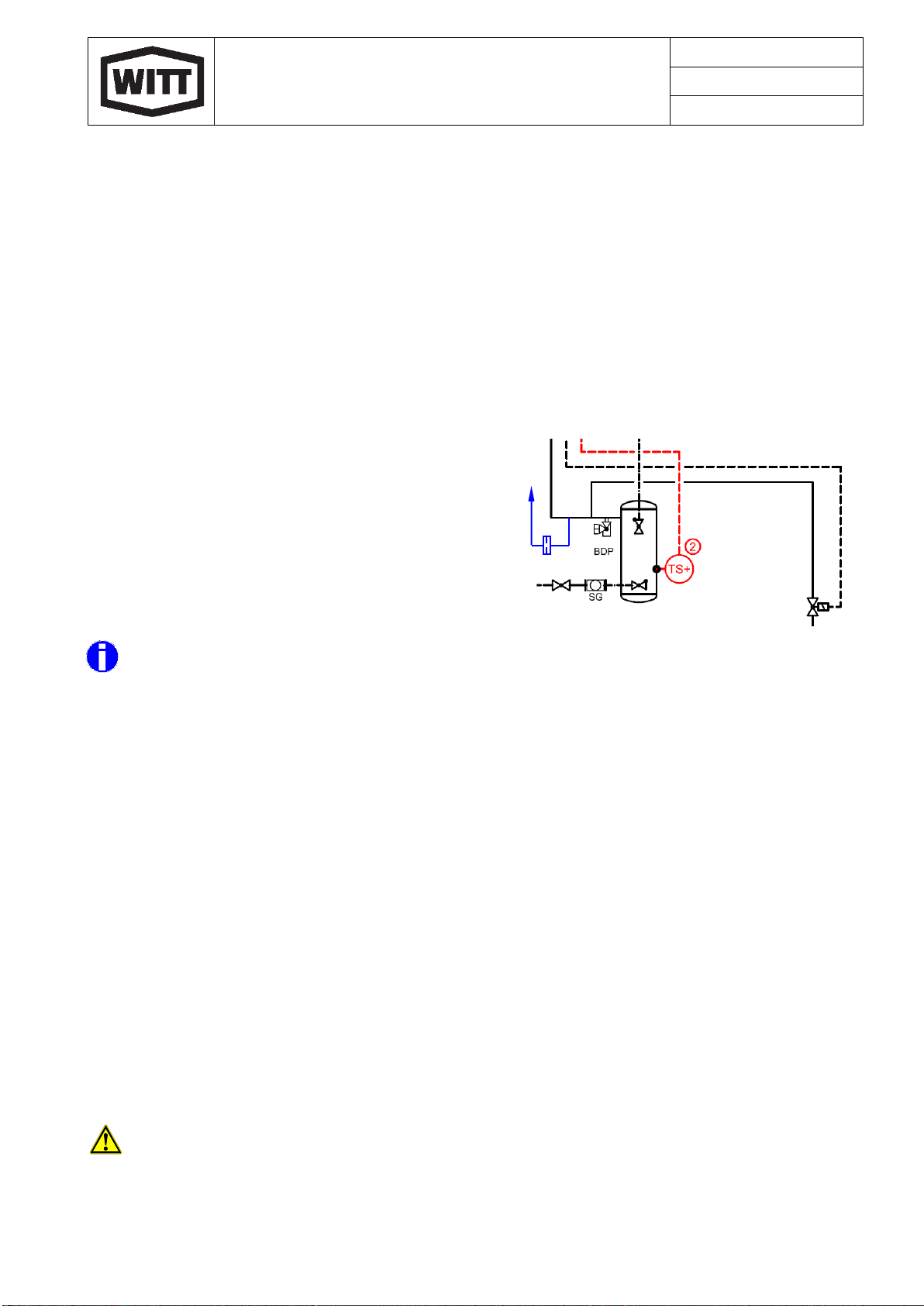

Preferably, the hot gas supply should be taken between oil separator and condenser (see “system schematic”,

6.10, tapping point A). Alternatively, aWITT high side float is suitable because warm gas is collected with sufficient

pressure at the top regulating valve (see “system schematic”, 6.10, tapping point B).

In both cases, the control line that is fed from a solenoid valve should be installed near to the BDP2, because

a) larger quantities of condensate may collect in front of the solenoid valve, but only refrigerant vapor is

allowed for the cycle.

b) The small volume of the control line between solenoid valve and BDP2 reduces the time for the return of

the internal piston (mechanical valve) to the initial position upon completion of a successful operation of

one cycle.

The internal damping of the BDP2 allows use of hot gas at high pressures.

6.5 Discharge of refrigerant/oil mixture

Due to the hot gas supply, an internal piston closes the connection to the low-pressure side of the refrigeration

system and pressure is build up within the BDP2 housing. Any liquid within the BDP2 is pushed outwards through

a check valve towards the compressor side.

6.6 Heat exchanger at the BDP2 outlet

We strongly recommend to pass the pushed out refrigerant/oil mixture through a heat exchanger to ensure that

all liquid refrigerant has been evaporated before returned to the compressor. The heating capacity should be

adequately selected such that any liquid refrigerant is completely evaporated. Sufficient time for evaporating

should also be considered, when an optional level senor is used to control the cycle.

WITT flow through evaporator DWR or small oil collectors, heated electrically or with hot gas, are proven for this

purpose (see “system schematic”, 6.10, DWR).

6.7 Oil return to the compressor

The oil return should be located within or before the compressor, where the pressure is slightly lower than the

pressure within the BDP2 housing.

The engineer in charge of the design should select an appropriate location for the oil return –depending on the

type and make of compressor. The following locations have been proven good practice:

•Screw compressors: in the suction line right in front of the suction stop valve (see “system schematic”,

6.10, Position Y)

•Piston compressors: in the return line between oil separator and crank case (see “system schematic”,

6.10, Position X)

When using evaporation pressure regulators it is important that the pressure does not get too low. When the

pressure difference to open the check valve (3 bar respective 1 bar) is reached, it is possible to continuously suck

liquid refrigerant from the surge drum through the BDP2.