\Manuals\5000Hardware

07/07/03

1

Series 5000 Hardware Guide

Hardware Guide for the Series 5000

Wizard™ Mat Cutting System

Contents

NOTES:.......................................................................................2

Chapter 1: The Board.................................................................................3

Air Clamp Removal...................................................................................................3

Air Clamp Temporary Fix..........................................................................................4

Air Clamp Replacement............................................................................................4

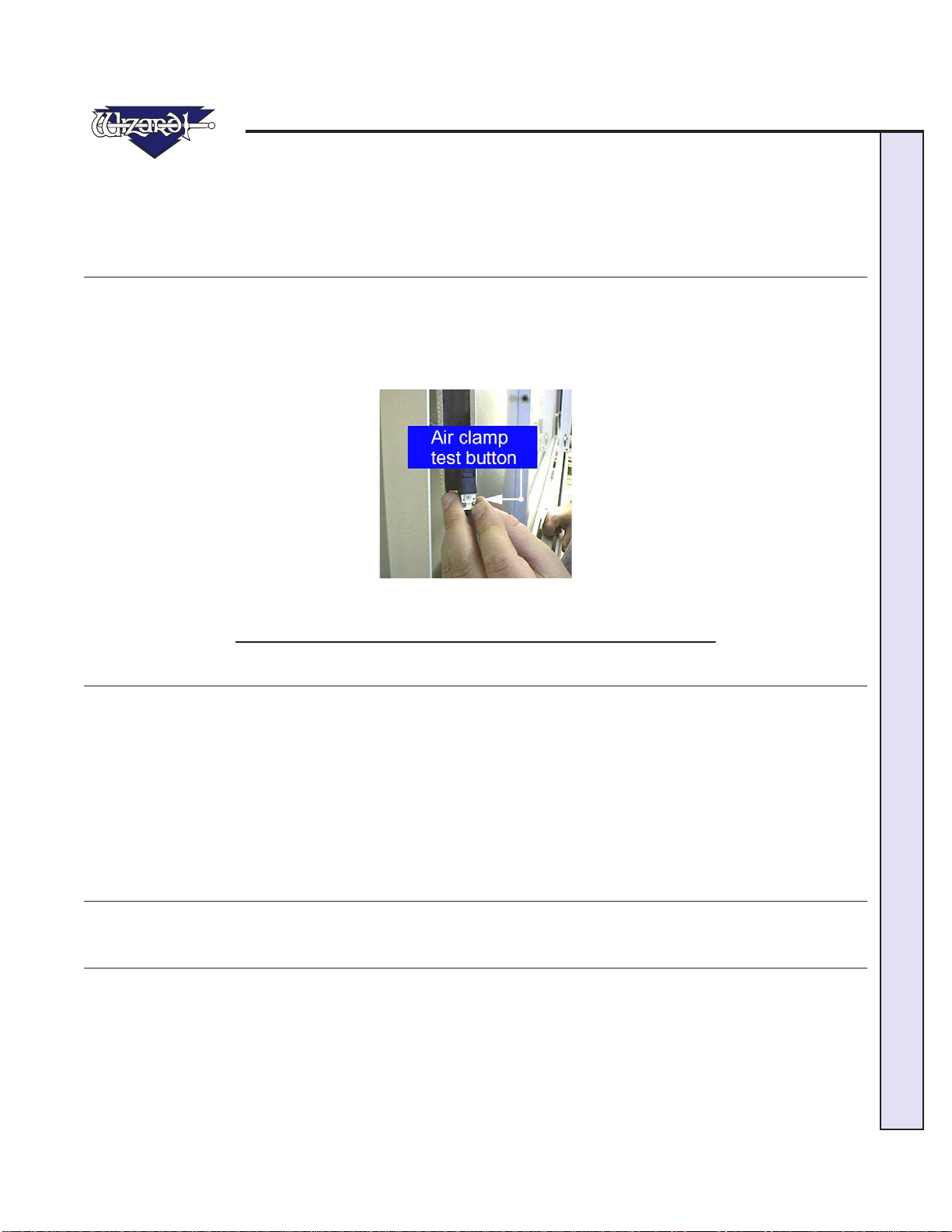

Air Clamp Test Button ..............................................................................................5

Gantry Alignment......................................................................................................5

Gantry Horizontal Tension .......................................................................................6

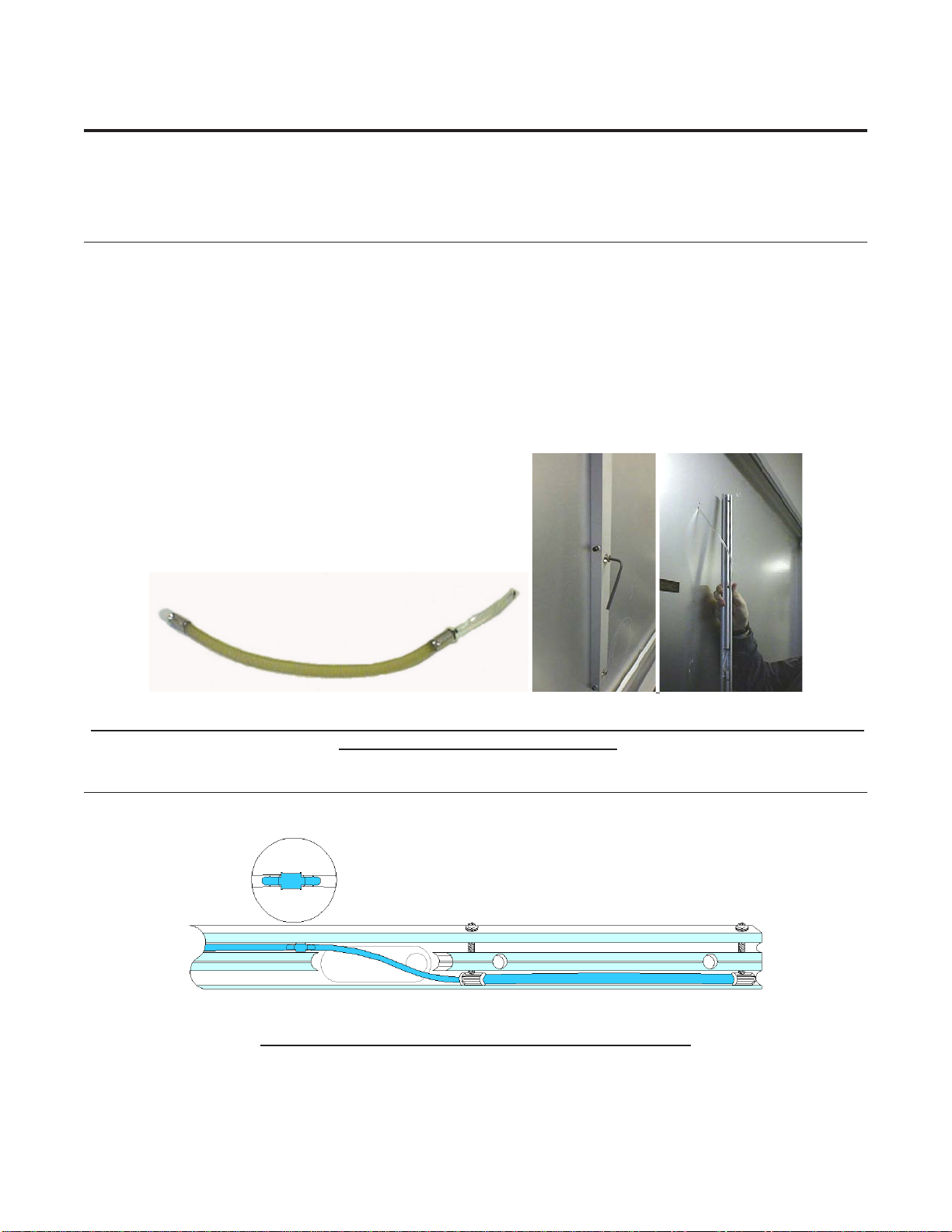

Travelling Cable.........................................................................................................7

Chapter 2: The CPU....................................................................................7

Modem Replacement................................................................................................7

Chapter 3: Driver Pak.................................................................................8

Driver Pak Replacement...........................................................................................8

No Power Available to the Driver Pak .....................................................................9

Chapter 4: The Gantry & Trolley Plate....................................................10

Gantry Alignment (See Board)...............................................................................10

Gantry Horizontal Tension (See Board)................................................................10

Gantry Removal.......................................................................................................10

Gantry Replacement...............................................................................................12

Gantry Wheel Adjustment ......................................................................................14

Trolley Vertical Tension..........................................................................................14

Trolley Plate Hinge replacement............................................................................15

Trolley Wheel adjustment.......................................................................................16

Chapter 5: The Head - Changing the Blade............................................16

Restarting the Cut...................................................................................................17