User manual SID116 –09.04.2015r. v.1.0

Contains

1. Safety and assembly rules.....................................................................................................................4

1.1 Safety rules ...................................................................................................................................................4

1.2 Assembly recommendation..........................................................................................................................4

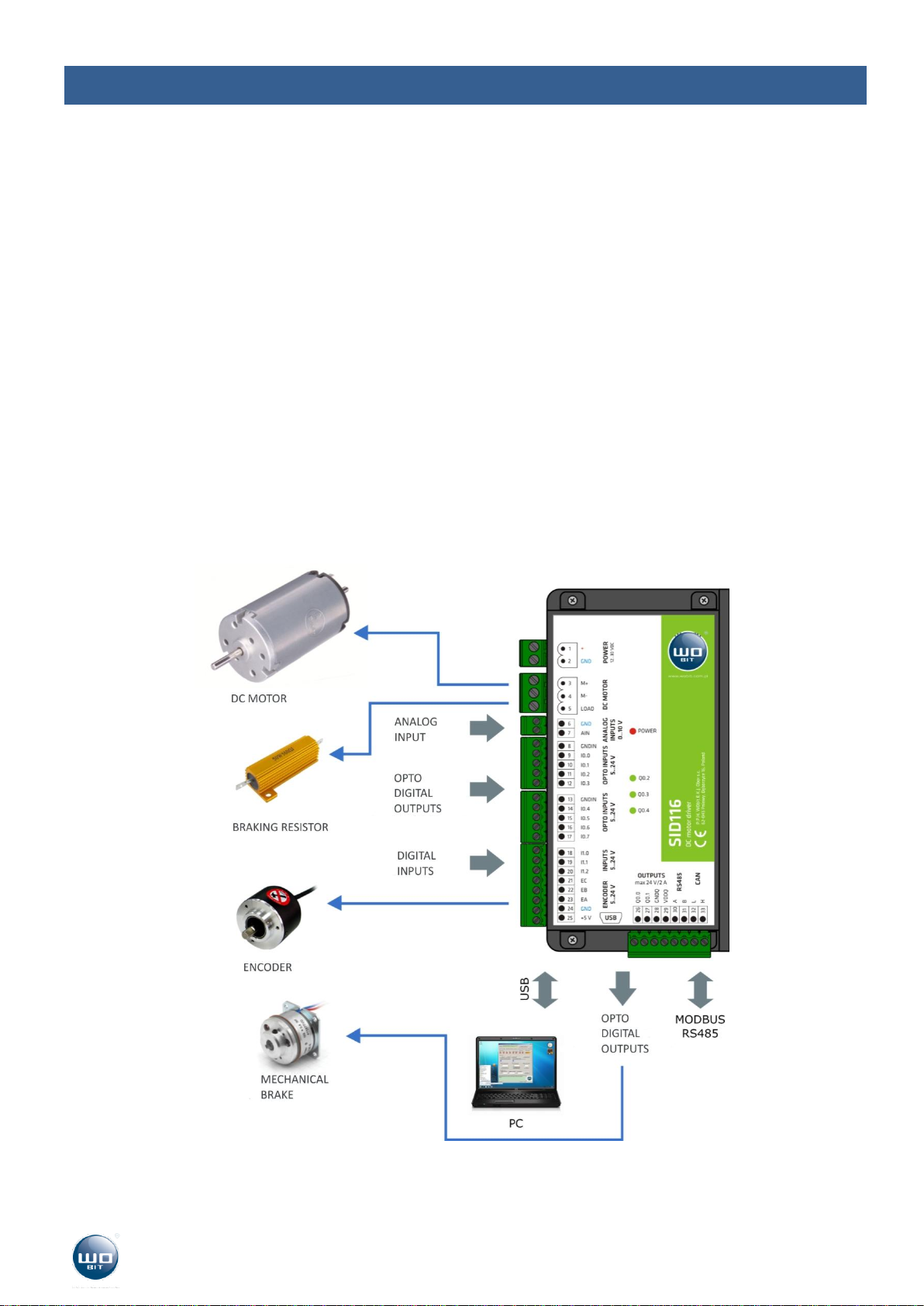

2. Introduction .........................................................................................................................................5

2.1 Intended use.................................................................................................................................................5

2.2 Functions ......................................................................................................................................................6

3. Device description ................................................................................................................................8

3.1 Connectors and indicators arrangement......................................................................................................8

3.2 Power supply ................................................................................................................................................9

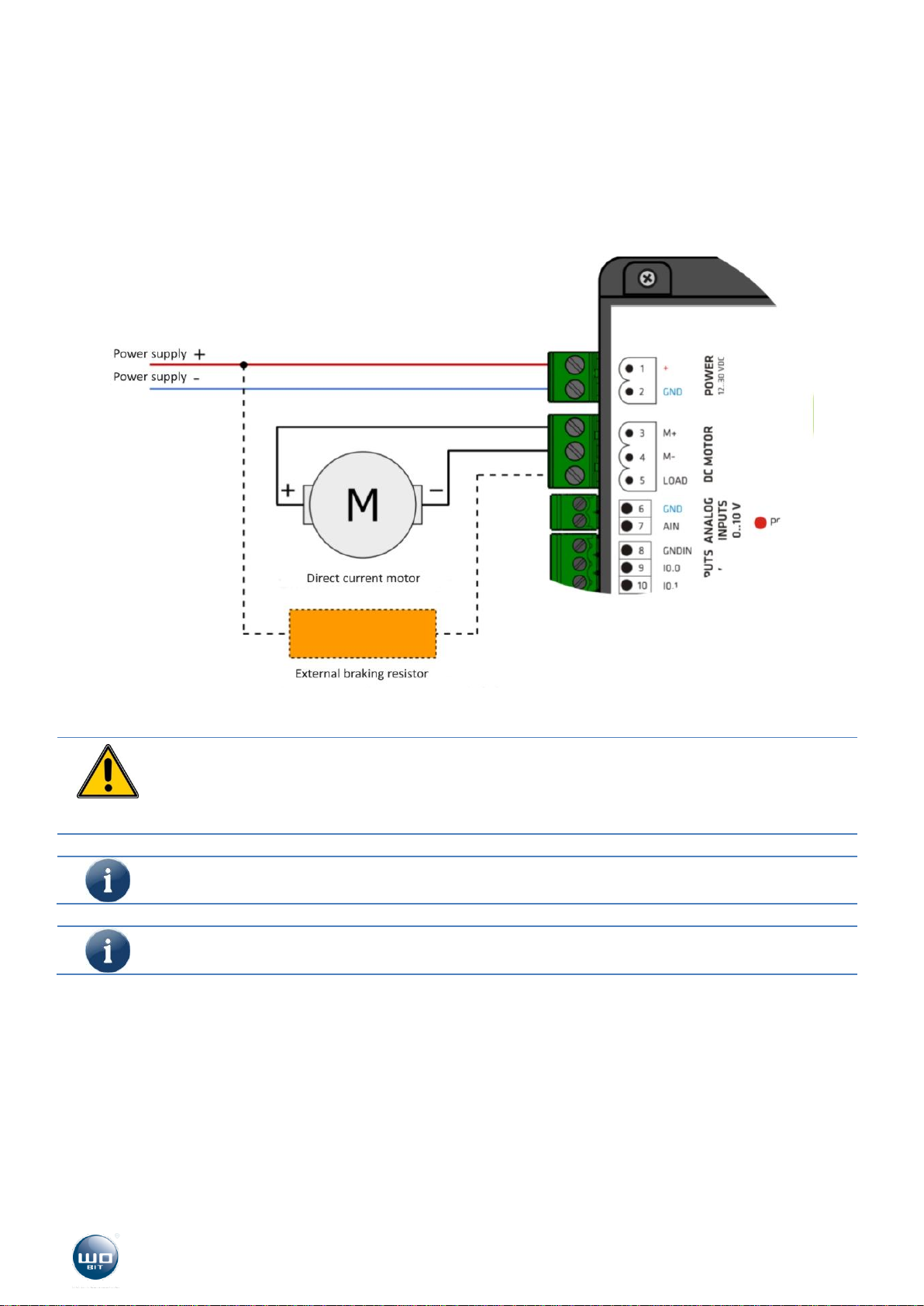

3.3 Motor and braking resistor.........................................................................................................................10

3.4 Incremental encoder ..................................................................................................................................11

3.5 Programmable inputs .................................................................................................................................12

3.6 Analog input ...............................................................................................................................................13

3.7 Programmable outputs...............................................................................................................................13

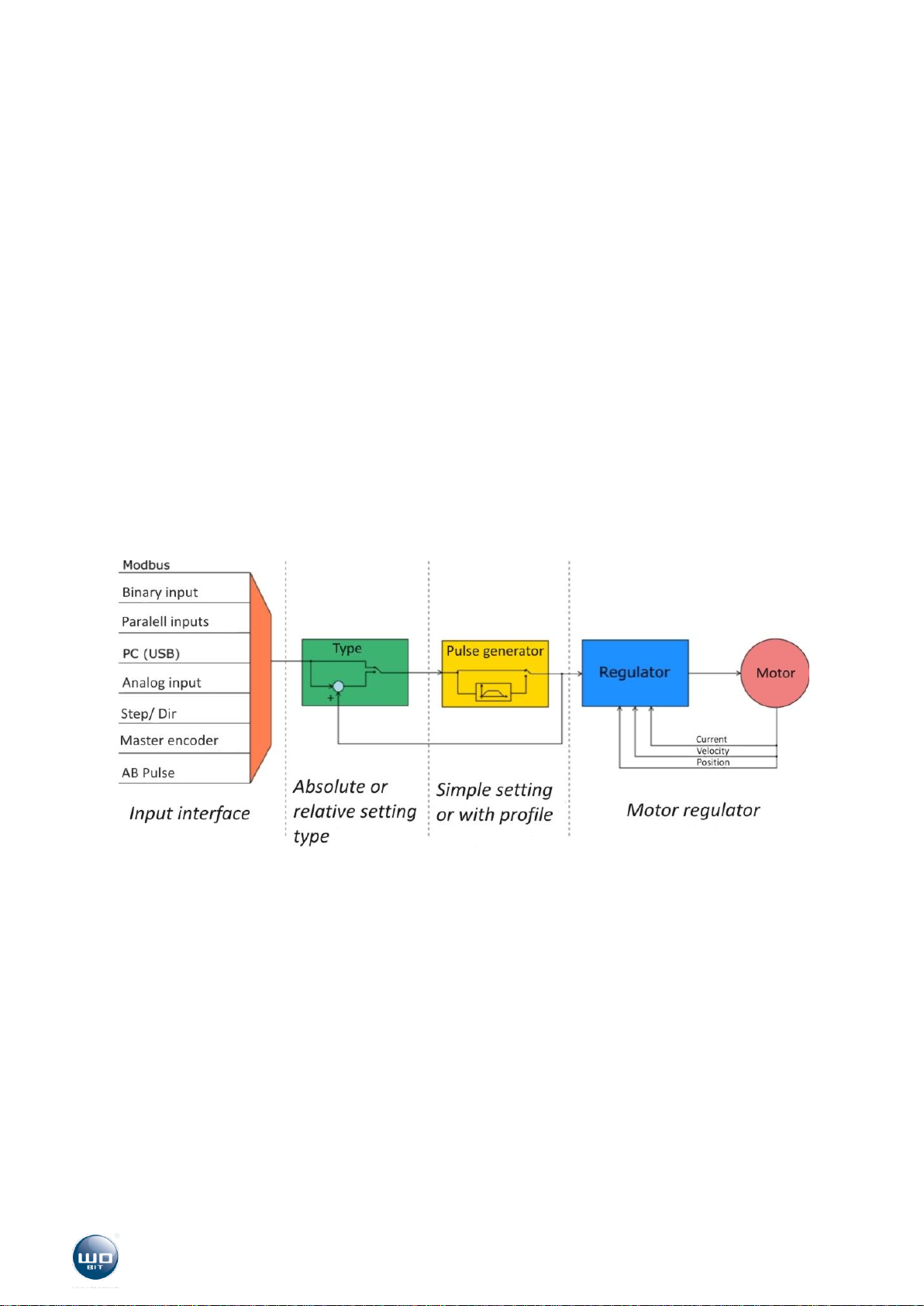

3.8 Control interfaces .......................................................................................................................................14

3.9 Communication interfaces .........................................................................................................................15

4. SID116 –PC software..........................................................................................................................16

4.1 USB connection with PC .............................................................................................................................16

4.2 Application interface description ...............................................................................................................16

5. Driver configuration............................................................................................................................25

5.1 Commissioning............................................................................................................................................25

5.2 Open loop operation (PWM mode)...........................................................................................................29

5.3 Regulator adjusting.....................................................................................................................................29

5.4 Current regulation ......................................................................................................................................31

5.5 Velocity regulation......................................................................................................................................32

5.6 Position regulator .......................................................................................................................................32

5.7 Dynamic braking (braking resistor).............................................................................................................34

5.8 Driver error handling. .................................................................................................................................36

6. MODBUS communication....................................................................................................................38

7. Record of changes...............................................................................................................................39

8. Technical parameters..........................................................................................................................40