SDC107 –DC motor driver user manual www.wobit.com.pl

Table of contents

1. Safety and assembly rules........................................................................................................................ 3

1.1 Safety rules ...................................................................................................................................................3

1.2 Assembly recommendation..........................................................................................................................3

2. Device description ................................................................................................................................... 4

2.1 Intended use.................................................................................................................................................4

2.2 Description of connectors and indicating lamps ..........................................................................................4

2.3 Power supply ................................................................................................................................................5

2.4 Driver’s outputs ............................................................................................................................................5

2.5 Connection example.....................................................................................................................................6

2.6 Error signaling and reset...............................................................................................................................6

3. Driver configuration................................................................................................................................. 6

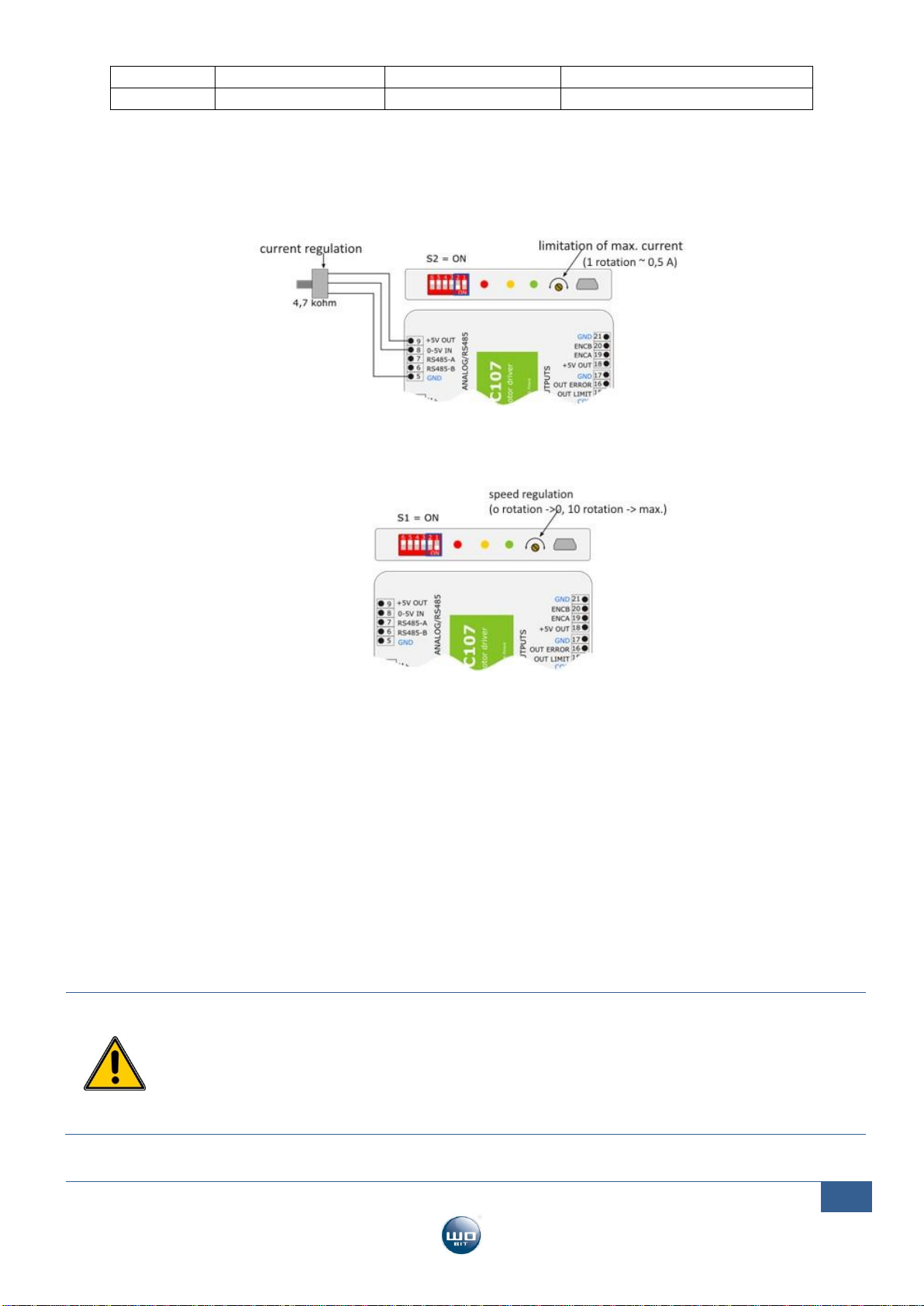

3.1 Speed/current regulation (S1/S2).................................................................................................................6

3.2 SOFT-START function (SOFT-START - S3) ......................................................................................................7

3.3 Dynamic brake function (BRAKE-STOP –S4) ................................................................................................7

3.4 Position limit inputs (LIMIT-LEVEL –S5) ......................................................................................................8

3.5 Auto-reverse function (Auto-reverse - S6) ...................................................................................................9

3.7 Driver software update.................................................................................................................................9

4Problems and solutions.......................................................................................................................... 10

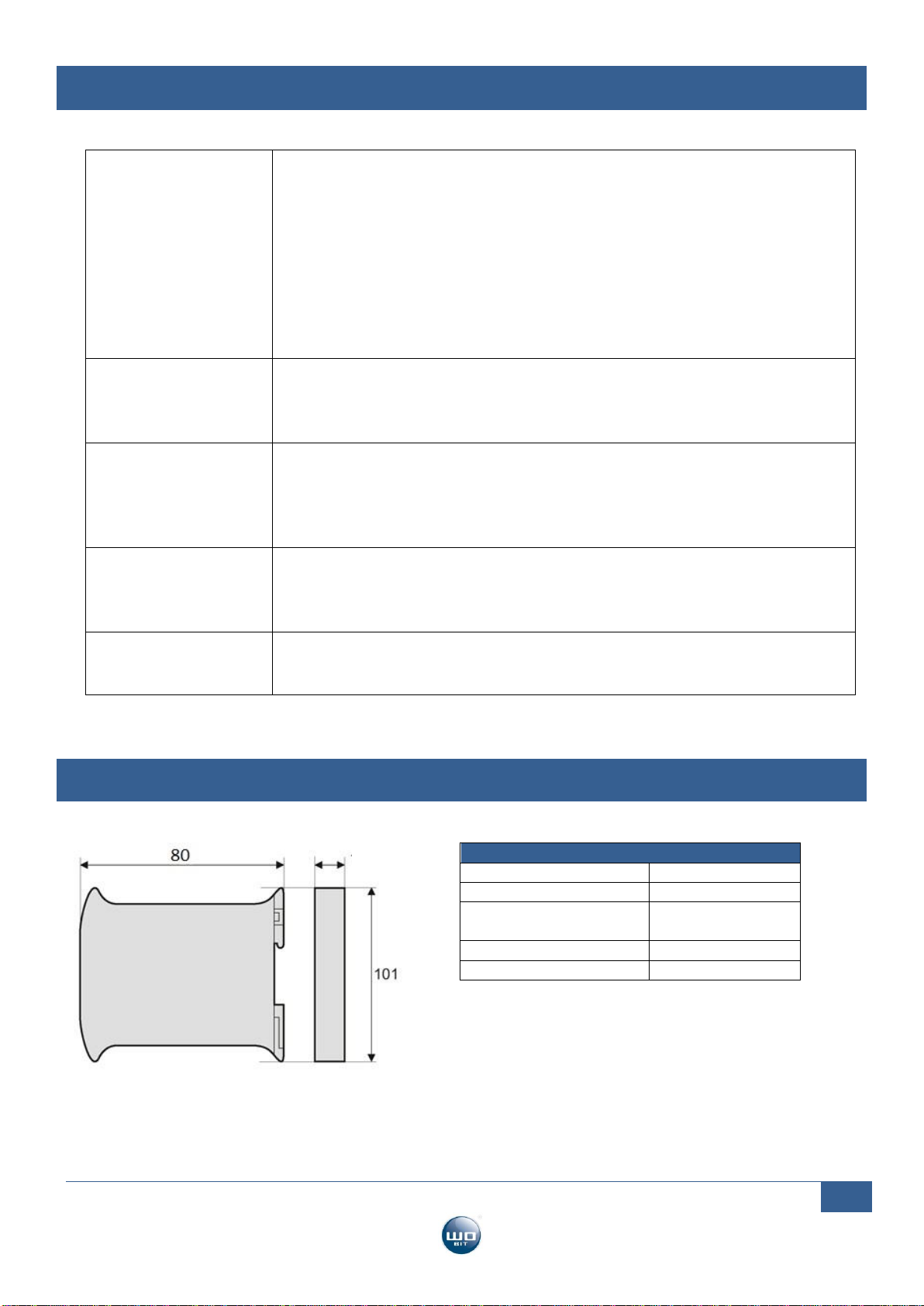

5Technical parameters............................................................................................................................. 10

Thank you for selecting our product!

This instruction will help you at correct service and accurate exploitation of described device.

Information included in this instruction were prepared with high attention by our specialists and is description of the product. Based on the

information should not be inferred a certain features or suitability for a particular application. This information does not release the user

from the obligation of own judgment and verification. P.P.H. WObit E.K.J. Ober s.c. reserves the right to make changes without prior notice.

Please read instructions below carefully and adhere to its recommendation

Please pay special attention to the following characters:

CAUTION!

Not adhere to instruction can cause damage or impede the use of hardware or software.