Manual -SMC50 –27.10.2014 –v.1.1

2. It is recommend to entwine the wires for motor in pairs. If generated noise creates problems or

wires for motor has to be longer, it is recommended to create shield by branding motor wires with

transmitting tape and connect it to mass. To reduce noises generated by supply wires it should be

used ferrite rings mounted on those wires.

3. As signal cables it can be used AWG14 cut up to 28 and for supplying AWG22 or bigger.

4. Signal wires should be move away from power supply line and motor wires for min. 10cm. At any

case it can’t be entwine together.

5. Regarding to the thermal factors (motor creates a lot of heat) it is recommended to install the

motor on aluminum plate, or on other part of the machine, which can take excess of a heat. At any

case is recommend to control motor temperature during first tests on the machine (max. motor

temperature 85C).

6. It is recommend to mount the controller as close to the motor as possible regarding to length of

the motor wires.

7. It is recommended to solder end of wires, especially of the motor (possibility of short circuit) or

after putting on them the spade tips to clamp it in device.

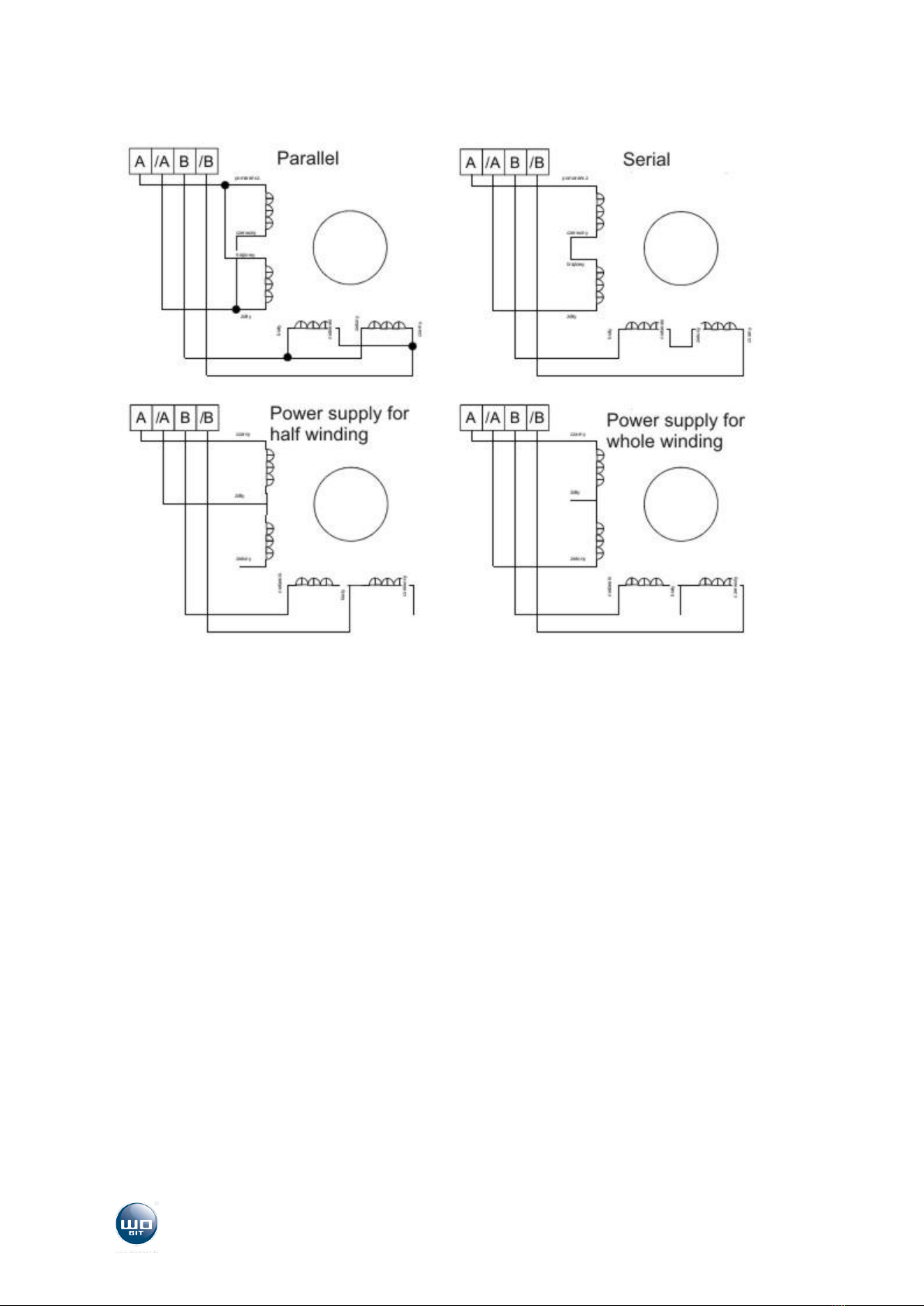

8. It is possible to make serial connection of bipolar windings (8-wires), when it is more important to

achieve rated torque, for example 1A winding controlled by rated current 1A or parallel by 2 bigger

current (about 1,4A for rated current of a half winding), when it is more important to achieve high

rotational speed of the motor (lower inductance of windings decides about faster rising the current

at winding). Nevertheless the temperature has to be controlled.

9. In case of transmitting power on different axle it is recommended to connect motor shafts and a

mechanism drives by clutch, specially adopted to this aim. It’s eliminate misalignment of installation

and prolong life time of motor bearings. This requirements very good fulfill Oldham clutches.

10. Do not screw, cut or drill motor shafts or its housing. Disassemble of the motor is possible only by

manufacturer, because after disassemble it the motor lose part of its torque as a result of

impairment of magnetic circuit. Disassemble of motor torque can also be caused by strong shocks

and vibrations.

11. To improve dynamic features can be used damper. Magnetic damper helps to reduce vibrations

and motor resonance and can enlarge maximal rotational speed even up to 2x.

12. Stepper motor is an electric device. Common rules regarding exploitation of electric devices are

binding. Before turn on of the controller, please make sure, that all moving parts of the machine or

motor itself will not interfere with other parts of the machine or will not hurt people.

13. Never connect supply cables of not discharged feeder (without load feeder can keep energy

accumulated in electrolytic capacitor for a long time). To discharge electrolytic capacitors is enough

to short-circuit low-impedance resistor clamp “+” with “-“ naturally at turn on power supply.