Problem Possible Cause Test/Action

No display lights check voltage to display light board.

No knob or lighted knob display No light in bezel

1Check voltage to bezel.

2Check the electrical connection.

3Replace the bezel.

REMOVE THE GAS VALVE BYPASS SCREW ORIFICE

Each gas valve has two bypass screw orifices installed on the

valve body. On sealed burners, this bypass screw is not

adjustable. If there is concern that the wrong bypass screw has

been installed into a gas valve, the size of the bypass screw can

be confirmed by comparing the number stamped on the bypass

screw to the

orifice chart

.

GAS PRESSURE TESTING

Testing gas supply pressure to a unit is a critical tool in properly

diagnosing a problem. Gas supply pressure issues are

common, and many times they are the root cause of recurring

issues. On CG units, each burner has an individual spark

module. There are no fuel-to-air ratio adjustments. Intermittent

sparking issues, flame quality issues, and ignition issues that

affect all burners are almost always related to gas pressure or

the supply regulator. Also, because there are three different

sizes of burner assemblies on each unit, pressure issues can

affect different sized burners in different ways. Gas pressure

must be checked by the method listed. The reason for this is so

that recorded pressures can be used to diagnose a specific

issue.

Natural Gas Specifications

The supply pressure to the inlet of the unit regulator must be

between a minimum of 7” water column (WC) and a maximum

of 14” WC.

The outlet of the regulator must be 5” - 5.5" WC.

The maximum pressure drop from maximum flow to low flow

must be less than .5” WC.

Liquid Propane Specifications

The supply pressure to the inlet of the unit regulator must be

between a minimum of 11” WC and a maximum of 14” WC. The

outlet of the regulator must be 10” - 10.5" WC.

The maximum pressure drop from maximum flow to low flow

must be less than .5” WC.

Connecting to the Unit Manifold

To check pressure on a CG unit:

1Uninstall the unit.

2Remove the burner pan.

3Once the burner pan is removed, reassemble the burners.

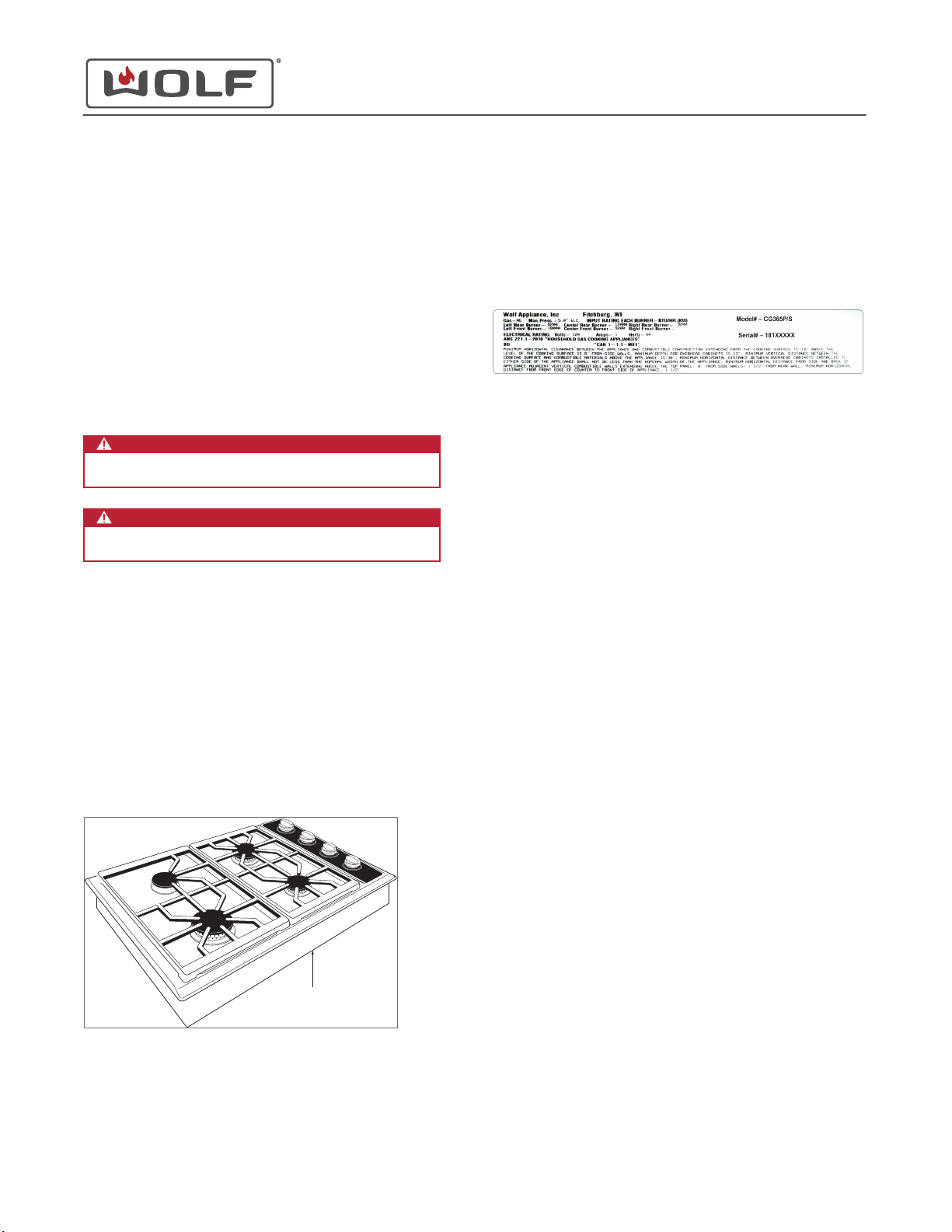

WARNING

Do not over-tighten the burner assembly

screws. The burner is designed to have the

burner pan between the burner assembly and

the orifice holder. A small amount of gas

leakage is normal during testing.

4Disconnect the main gas tube from a 9.2 K orifice holder,

and connect the manometer to the main gas tube. Set the

burner to High.

WARNING

Professional models have bezel connectors that may

short to the knob. Connect the bezel, and install it

loosely in the display bracket.

Static Pressure

Static pressure is the gas pressure when there is no gas

movement. Taking this pressure is not an effective diagnostic

tool. Pressure will equalize across any regulator in the gas

supply system. It is not possible to determine what pressure

should be recorded when checking any part of unit by static

pressure.

Low Flow Pressure

Low flow pressure is manifold pressure on the unit taken when

there is minimum gas flow. This pressure will provide an idea if

the unit regulator is operating properly. Low flow pressure must

be within PLUS .5” WC and MINUS 0.0” WC of the

designated manifold pressure. Low flow pressure on CG units is

obtained by lighting one of the 9.2 K burners in the simmer

range, while connected to the other 9.2 K burner main gas line.

Example: Low flow manifold pressure reading taken with left

rear burner on low simmer on CG365T/S with natural gas was

5.4” WC. Low flow pressure is good. It falls in range of 5” - 5.5"

WC.

Example: Low flow manifold pressure reading taken with

right front burner on low simmer on CG304P/S-LP with liquid

propane (LP) was 9.7” WC. Low flow pressure is bad. Outside

of range of 10” - 10.5" WC.

Maximum Flow Pressure

Maximum flow pressure is the manifold pressure when all

burners are set to High. It is normal for the pressure to drop

slightly. The difference in pressure from the low flow pressure to

the maximum flow pressure must be less than .5" WC.

Example: Low flow manifold pressure is 5.4" WC on

CG365T/S. Maximum flow manifold pressure is 5.2" WC.

Pressure test is good. Pressure drop was .2" WC, and low flow

was 5.4" WC. Unit is not experiencing a gas pressure issue.

CG Series Gas Cooktops Service Manual

service.subzero.com

824779 REV. C 6