Heat Recovery unit CWL-300(B) / CWL-400(B) with option PCB 3

Application Chapter 1

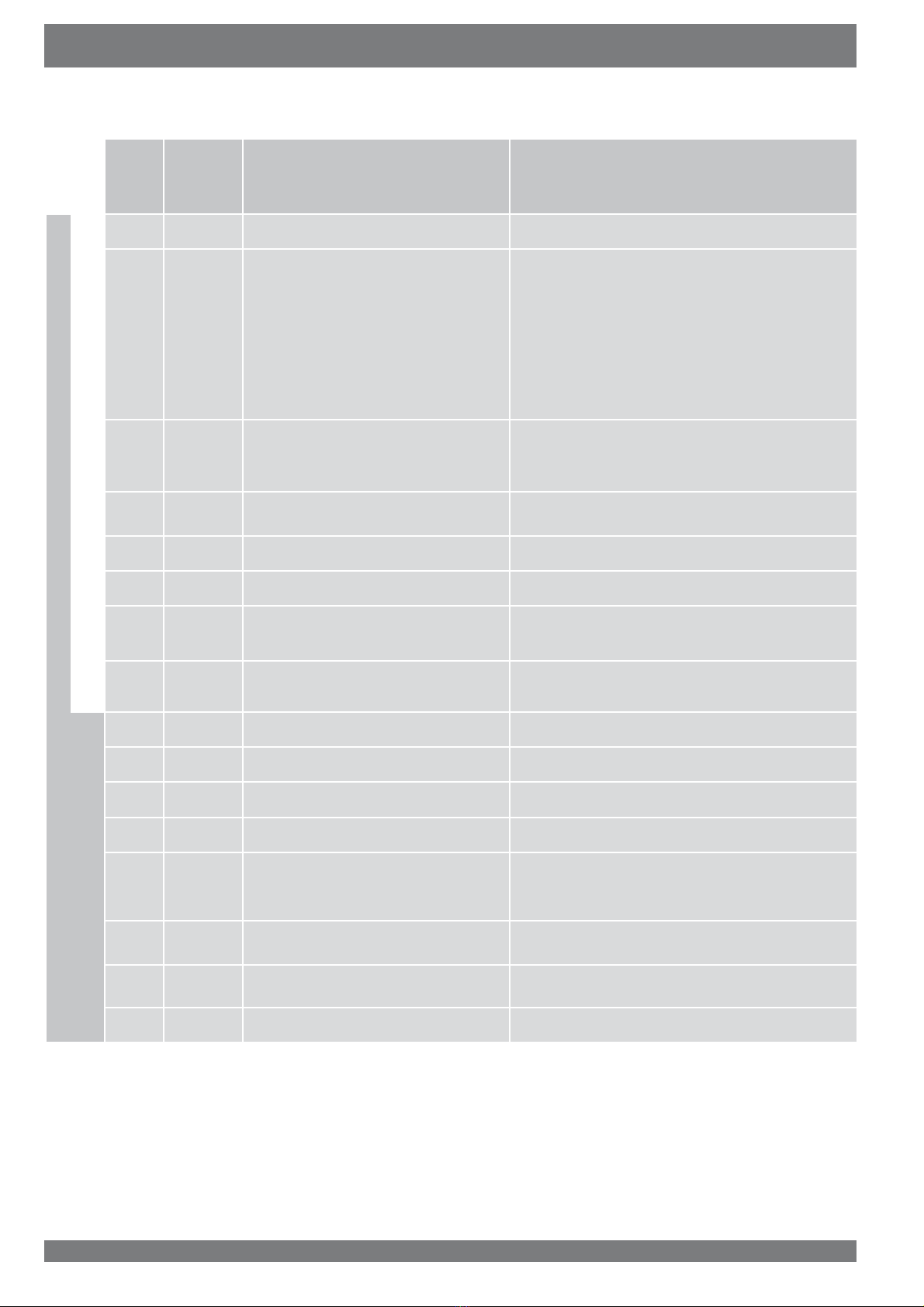

The functionality of CWL 300 & 400 can be extended with the

VHSDUDWHO\DYDLODEOHRSWLRQSFE

7KLVRSWLRQSFEDOORZVFRQQHFWLRQRIYDULRXVH[WUDV7KLVPD-

QXDO GHVFULEHV KRZ WKH YDULRXV FRQQHFWLRQV PXVW EH PDGH

(§ 2.2 and chapter 6) and what the setting parameters are

(§ 4.3). For general information on the CWL-series we refer to

the installation instructions of the CWL- 300/400.

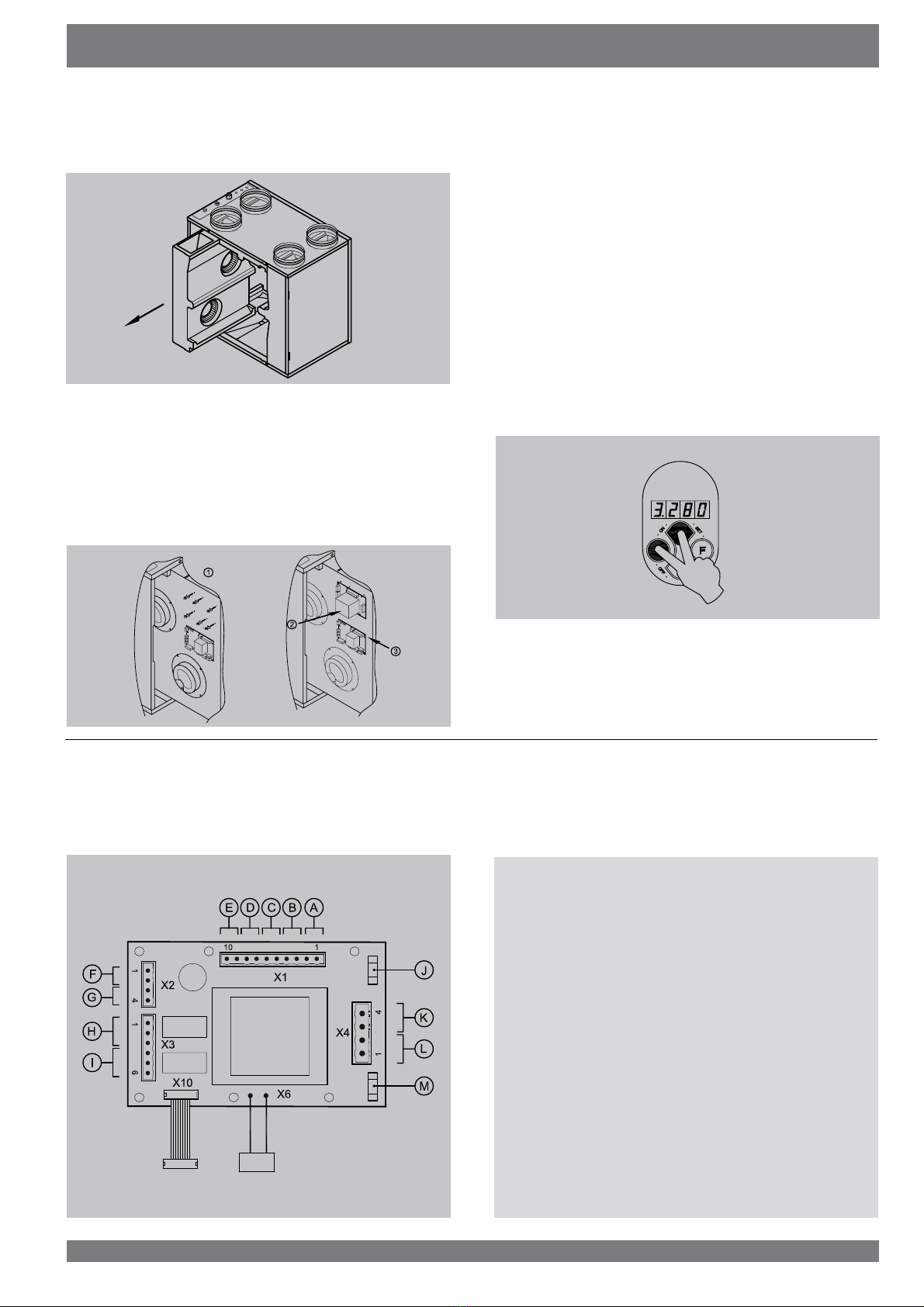

The CWL-appliance can be equipped with an option pcb.

,WSURYLGHVWKHIROORZLQJIXQFWLRQV

Input 0-10 V for a carbon dioxide sensor

When there are more people in the home, more CO

2

is produ-

FHGDQGWKHQWKLVVHQVRU DXWRPDWLFDOO\ LQFUHDVHV WKHYHQWLOD-

tion quantity. For that purpose the CO

2

VHQVRUPXVWKDYHDWR

PD[LPXP9FRQWURO

Input 0-10 V for a moisture sensor

When the moisture content in the dwelling increases, for in-

stance when someone is taking a shower, this sensor automa-

WLFDOO\ LQFUHDVHV WKH YHQWLODWLRQ TXDQWLW\ 7KH PRLVWXUH VHQVRU

PXVWKDYHDWRPD[LPXP9FRQWURO

Switching input for bedroom valve.

:LWKWKLVLQSXWPDNHFRQWDFWWKHEHGURRPYDOYHFDQEHFRQ-

trolled, for example by using a time switch.

Switching output for bedroom valve 24 VAC

7KH RSWLRQ SFE KDV D EXLOWLQ FRQWURO IRU D 9$& EHGURRP

YDOYH6XFKDYDOYHFDQGLUHFWO\EHFRQQHFWHGWRWKHSFE7KH

YDOYH FDQ EH FRQWUROOHG IURP WKH VZLWFKLQJ LQSXW IRU WKH EH-

GURRPYDOYH

6ZLWFKLQJRXWSXWIRU9$&ÀXHJDVVDIHW\YDOYH

If it is recommended to combine the discharge of the central

heating and the CWL appliance, the CWL connection to the

MRLQWGLVFKDUJHPXVWEHSURWHFWHGZLWKDÀXHJDVVDIHW\YDOYH

7KHYDOYHFDQGLUHFWO\EHFRQQHFWHGWRWKLVSFE:KHQWKHRXW-

SXWIDQKDVVWRSSHGRULILWLVGHIHFWLYHWKLVYDOYHLVDFWLYDWHG

Control for preheater up to 1000 W

7KHSUHKHDWHUHQVXUHVWKDWWKHLQSXWDLULVNHSWDERYH&VR

WKH&:/DSSOLDQFHFDQFRQWLQXHWKHEDODQFHGYHQWLODWLRQDOVR

DW YHU\ ORZ DWPRVSKHULF WHPSHUDWXUHV

The option pcb con-

tains a control for a preheater up to 1000 W.

The preheater can

be connected to the option pcb without separate control. The

hook-up wire of the preheater must be fed into the appliance;

WKH 9 SRZHU FDEOH PXVW VHSDUDWHO\ EH FRQQHFWHG WR WKH

option pcb (see § 6.6).

It is also possible to connect a preheater to the basic pcb of the

CWL-appliance if no option pcb is mounted (see §9.4 of the

installation instructions CWL-300/400).

Control for postheater up to 1000 W

The postheater ensures that the supply air that is blown into

the dwelling can be kept at the preset temperature. That way

additional warmth can be brought into the dwelling. The option

pcb contains a control for a postheater up to 1000 W. The pos-

theater can be connected to the option pcb without separate

control. The hook-up wire of the postheater must be fed into

WKHDSSOLDQFHWKH9SRZHUFDEOHPXVWVHSDUDWHO\EHFRQ-

nected to the option pcb (see § 6.5).

Two freely programmable make contact inputs

These inputs make it possible :

• to open the bypass without regard for the temperature con-

ditions;

WRVZLWFKWKHLQSXWRURXWSXWORZRUKLJKWRFLUFXPYHQWWKH

frost protection;

• to switch the input low when the bypass opens.

Switch input for incidents

$¿UHDODUPFDQEHFRQQHFWHGWRWKLVLQSXW$VVRRQDVWKH¿UH

alarm is triggered, the appliance switches to incident mode.

As standard that is set to switch off the fans.