9

05 THERM CONNECT

WOLF run around coil systems

05.04.02 Attachment to lifting devices

Attachment to lifting devices must be carried out in accordance with the specifications in these operating instruc-

tions.

For fastening the suspension ropes or chains to the load suspension bracket, fastening elements appropriate to the load,

e.g. shackles, must be used! For crane transport, all applicable safety regulations according to DGUV regulation 52 Cranes

and DGUV 500 chapter 2.8 must be observed (DGUV german: German Statutory Accident Insurance).

Attention! The maximum load capacity per delivery unit incl. dead weight of the lifting aids must not be exceeded!

Exceeding the load capacity may result in damage to the delivery unit. There is a danger to life.

WK-com type max. load capacity / delivery unit max. load capacity / corner connector

N, N-W, H, H-W 2.500 kg 625 kg

S, S-W 3.000 kg 750 kg

When unloading, lifting and assembling, do not lift several equipment units together. Lift units with more than 4

lifting lugs only with a crane traverse.

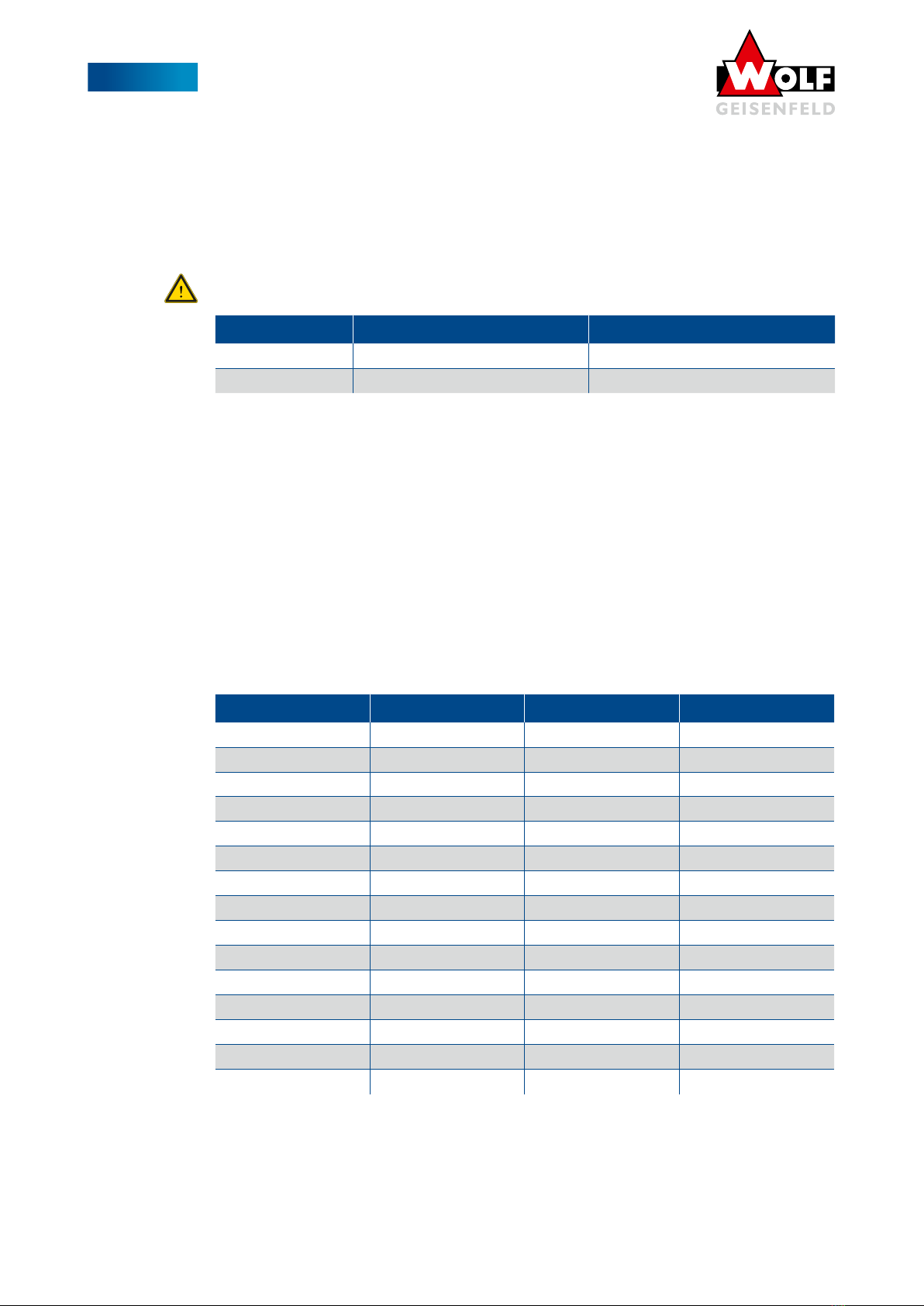

The rope angle (S) must not exceed 60°.

The angle of inclination (A) must not exceed 30°.

The arrangement and dimensioning of the lifting lugs refers to a rope angle of 60° (corresponds to an angle of incli-

nation of 30°).

Larger rope or inclination angles cause an overload of the lifting straps and lead to damage to the device.

The length of the transport chain or ropes must at least correspond to the distance between the lifting straps.

Please take the prescribed values from the table “05.04.03 Standard values for attachment to lifting devices”.

The values in the table refer to a rope angle of 60° (= angle of inclination 30°).

05.04.03 Standard values for fastening to lifting devices

L = length of the module

width of the module H = hook height K = chain length

6,00 m 3,00 m 5,81 m 6,71 m

6,00 m 1,65 m 5,40 m 6,22 m

6,00 m 1,00 m 5,30 m 6,08 m

5,00 m 3,00 m 5,06 m 5,84 m

5,00 m 1,65 m 4,56 m 5,27 m

5,00 m 1,00 m 4,41 m 5,09 m

4,00 m 3,00 m 4,33 m 5,00 m

4,00 m 1,65 m 3,75 m 4,33 m

4,00 m 1,00 m 3,57 m 4,12 m

3,00 m 3,00 m 3,67 m 4,24 m

3,00 m 1,65 m 2,97 m 3,42 m

3,00 m 1,00 m 2,73 m 3,15 m

2,00 m 1,65 m 2,24 m 2,59 m

2,00 m 1,00 m 1,93 m 2,23 m

1,00 m 1,00 m 1,21 m 1,40 m