Component Removal

Induction Range (IR) Series

Induction Range (IR) Series

3-5 #827176 - Revision A.1 - December, 2016

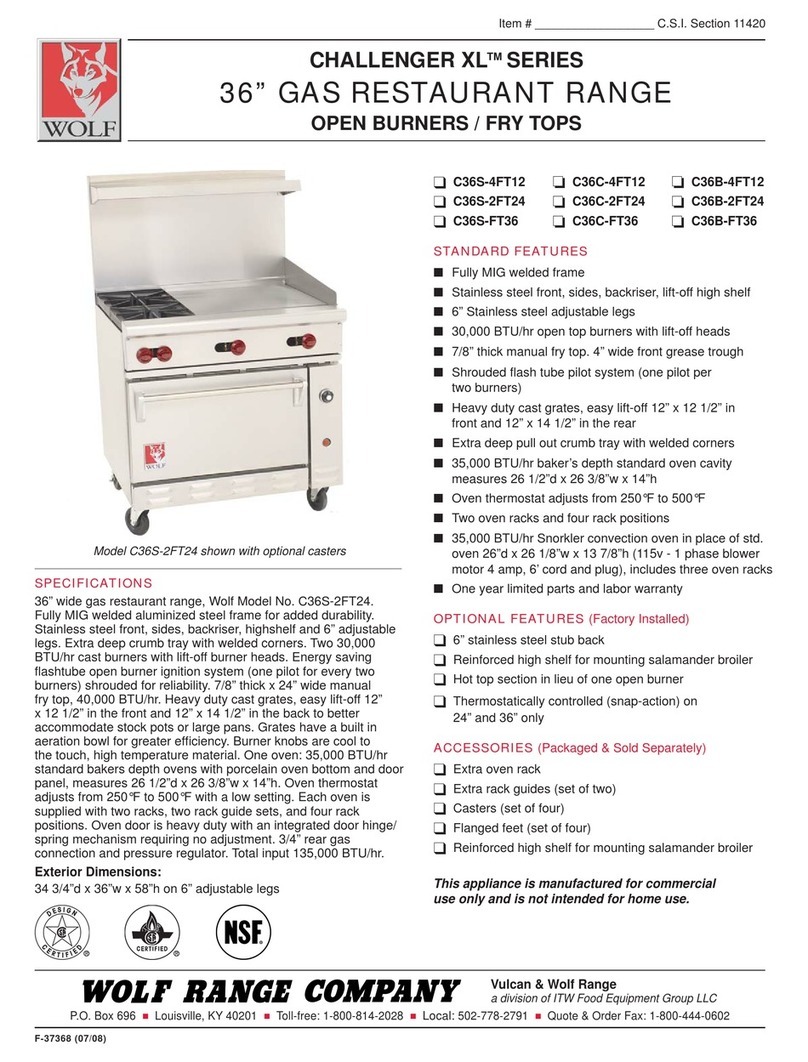

Handle Removal

The handle bar is locked between the two handle

standoffs that are attached to the door skin.

To remove the handle, first remove the door skin, then

(See Figure 3-7):

Extract the screws from handle pad that pass1

through the door skin into the handle standoffs.

Remove the standoffs and handle bar.2

Gasket Removal

The oven gasket is a two part gasket with one part

around the top and the two sides of the cavity, and the

second part at the bottom of the oven cavity. The gas-

kets are attached to the oven face by a series of spring

pins.

To remove the gasket, first open the oven door, then

(See Figure 3-8):

Use needle nose pliers to compress the spring pins1

on the back of the gasket.

Remove the gasket.2

Rack Removal

There are three types of racks in the oven. The flat rack

which can be used in any position in the oven, the bent

rack, designed to be used in the lowest position and to

be pulled out on to the door, and the sliding rack which

rolls out on sliding rails.

To remove a rack, first open the oven door, then (Not

Shown):

Pull the rack forward until it stops.1

Lift the front of rack up and pull the rack from the2

oven.

Rack Guide Removal

To remove the rack guides, first remove the racks, then

(See Figure 3-9):

Lift the rack guide up.1

Pull the top of the rack guide toward the center of2

the oven, disengaging it from the shoulder screws.

Pull the rack guide forward from the oven.3

Figure 3-7. Handle Removal

Figure 3-8. Gasket Removal

Figure 3-9. Rack Guide Removal

•The rails on the sliding rack move by themselves.

Keep hands and fingers out of the line of travel.