2

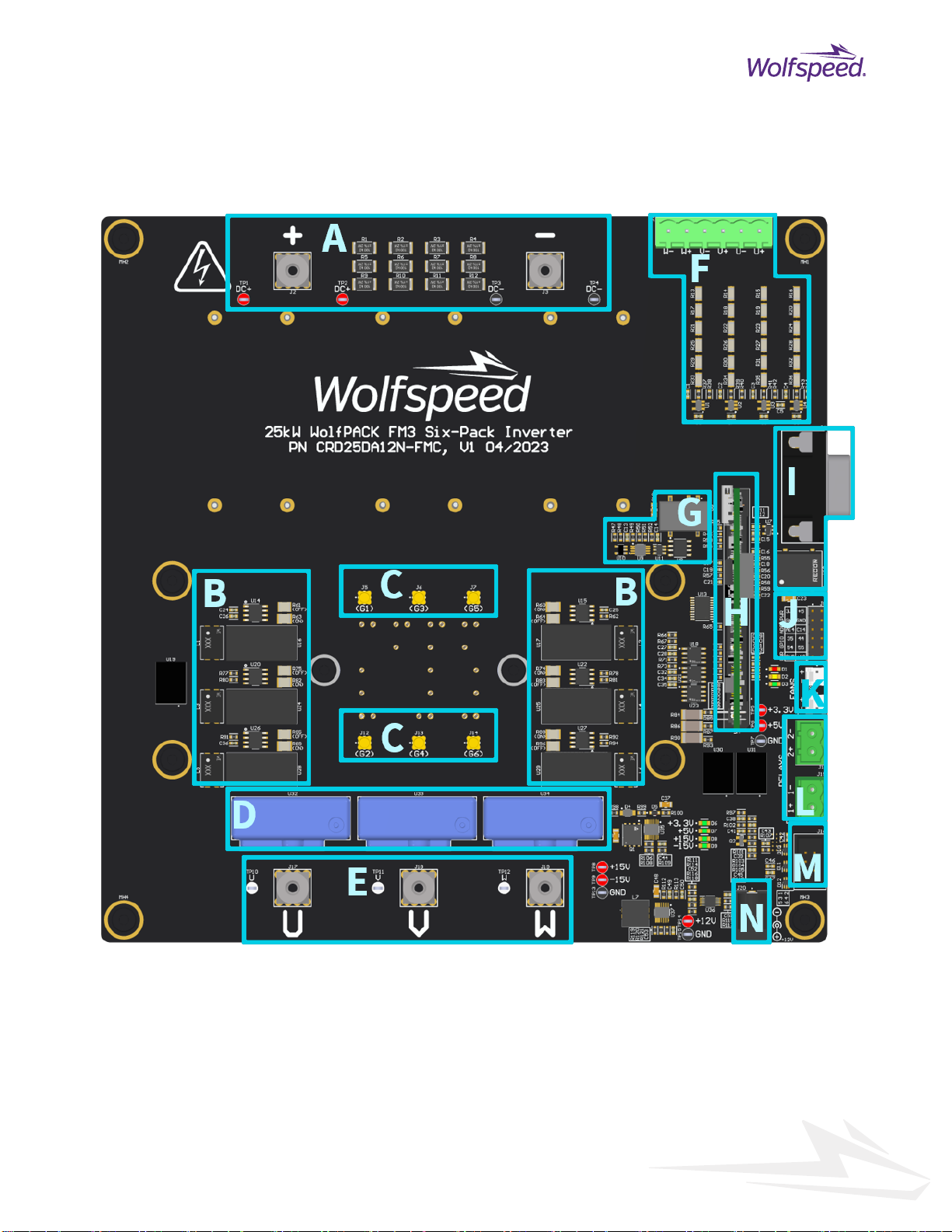

PRD-07560 REV. 0, May 2023 CRD25DA12N-FMC 25 kW Three-Phase Inverter User Guide

© 2023 Wolfspeed, Inc. All rights reserved. Wolfspeed® and the Wolfstreak logo are registered trademarks and Wolfspeed

WolfPACK™ and the Wolfspeed logo are trademarks of Wolfspeed, Inc. Other trademarks, products, and company names are the

property of their respective owners and do not imply specific product and/or vendor endorsement, sponsorship, or association.

All parts of this application note are provided in English, and the Cautions are provided in English, Mandarin,

and Japanese. If the end user of this board is not fluent in any of these languages, it is your responsibility to

ensure that they understand the terms and conditions described in this document, including without limitation

the hazards of and safe operating conditions for this board.

本文件中的所有内容均以英文书写,“注意”部分的内容以英文、中文和日语书写。作为本板子的终端

用户,即使您不熟悉上述任何一种语言,您也应当确保正确理解本文件中的条款与条件,包括且不限于

本板子的危险隐患以及安全操作条款。

当書類のすべての内容は英語で書きます。「注意点」の内容は英語、中国語、また日本語で書きます。

当ボードの端末使用者は上記の言語が一つでもわからないなら、当端末使用者は当書類の条約と条件

が理解できるのを確保すべきです。そして、当ボードの危険や安全に使用する条件を含み、また限り

ません。

Note: This Wolfspeed-designed evaluation hardware for Wolfspeed®components is a fragile, high-voltage, high-

temperature power electronics system that is meant to be used as an evaluation tool in a lab setting and to be

handled and operated by highly qualified technicians or engineers. When this hardware is not in use, it should

be stored in an area that has a storage temperature ranging from -40° Celsius to 105° Celsius. If this hardware

is transported, to avoid any damage to electronic components, special care should be taken during

transportation to avoid damaging the board or its fragile components and the board should be transported

carefully in an electrostatic discharge (ESD) bag, or with ESD or shorting protection that is the same as, or

similar to, the protection that is or would be used by Wolfspeed when shipping this hardware. Please contact

Wolfspeed at https://forum.wolfspeed.com/ if you have any questions about the protection of this hardware

during transportation. The hardware does not contain any hazardous substances, is not designed to meet any

industrial, technical, or safety standards or classifications, and is not a production-qualified assembly.

本样机(易碎、高压、高温电力电子系统)由Wolfspeed为评估其功率半导体产品而设计,用以作为在实

验室环境下由专业的技术人员或工程师处理和使用的评估工具。本样机不使用时,应存储在-40oC~105oC

温度范围的区域内;如需运输样机,运输过程中应该特别小心,避免损坏电路板等易碎组件。如果您对

此硬件在运输之中的保护有任何疑问,请联系https://forum.wolfspeed.com/。样机应放置在防静电包装

袋内谨慎运输,避免损坏电子组件。本样机不含任何有害物质,但其设计不符合任何工业、技术或安全

标准或分类,也不是可用于生产的组件。

このクリーのコンポーネント用評価ハードウェアは壊れやすい高電圧の高温パワーエレクトロニクスシステムで

あり、ラボ環境での評価ツールとして使用され、優秀な技術者やエンジニアによって処理され、操作されること

を意図している。ハードウェアが使用されていない場合、保管温度が-40℃から105℃の範囲に保管してくださ

い。このハードウェアを輸送する場合は、輸送中にボードまたはその壊れやすいコンポーネントに損傷を与え

ないよう特別な注意を払う必要がある。また電子部品の損傷を避けるためにボードを静電気放電(ESD)袋に

静置して慎重に輸送するべき。ハードウエアの輸送中の保護について質問があれば、

https://forum.wolfspeed.com/に連絡してください。ハードウェアには危険物質が含まれていないが、工業的、

技術的、安全性の基準または分類に適合するように設計されておらず、生産適格組立品でもない。