Wolturnus Acve Wheelchair User’s Manual 2018 Wolturnus Acve Wheelchair User’s Manual 2018Acve Wheelchair Acve Wheelchair

Introducon

Introducon

1.3 Usage

The wheelchair’s modular design and versality make it suitable for users who have diculty walking or who

have a mobility handicap as a result of:

• Paralysis

• Loss of limbs (leg amputaon)

• Limb defects or deformies

• Damaged or defecve limbs

• Other illnesses

When adapng the wheelchair for the user, the following should be taken into account:

• Body height and weight (max. load 120-250 kg.)

• Physical and mental constuon

• Age

• Residenal circumstances

• Surroundings

1 Introducon

1.1 Foreword

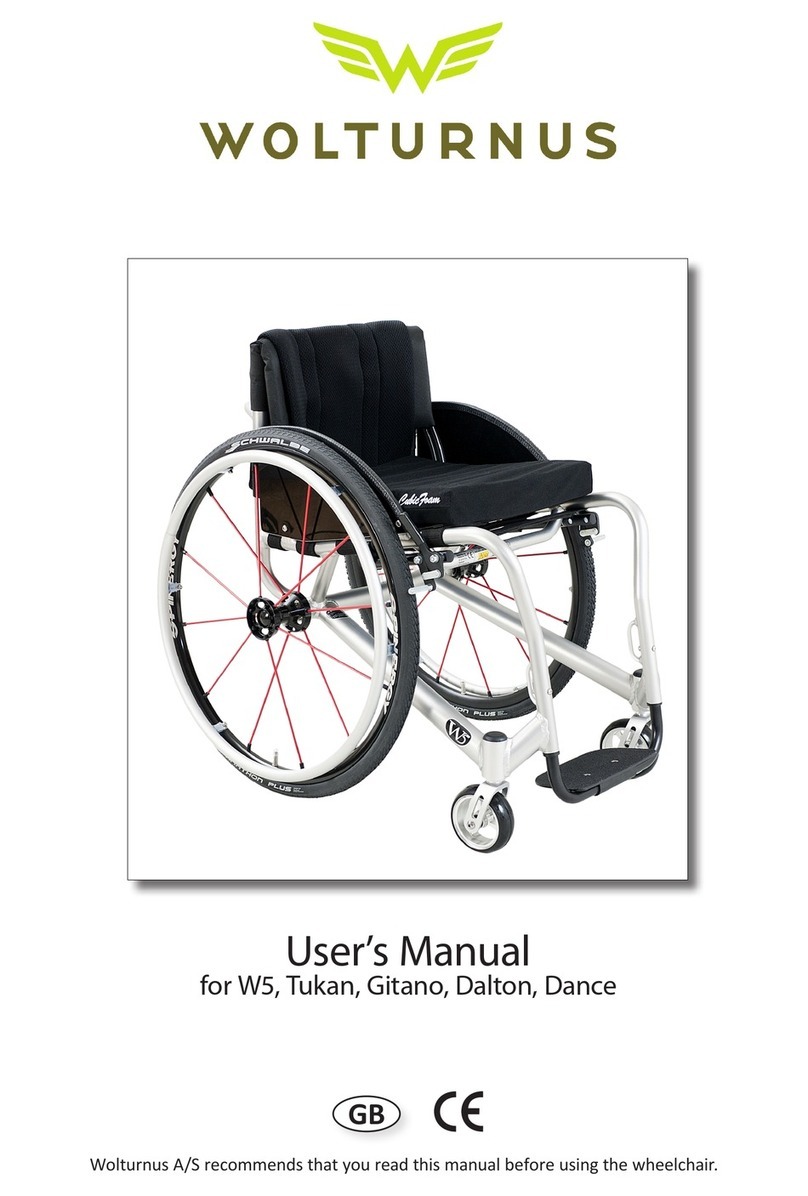

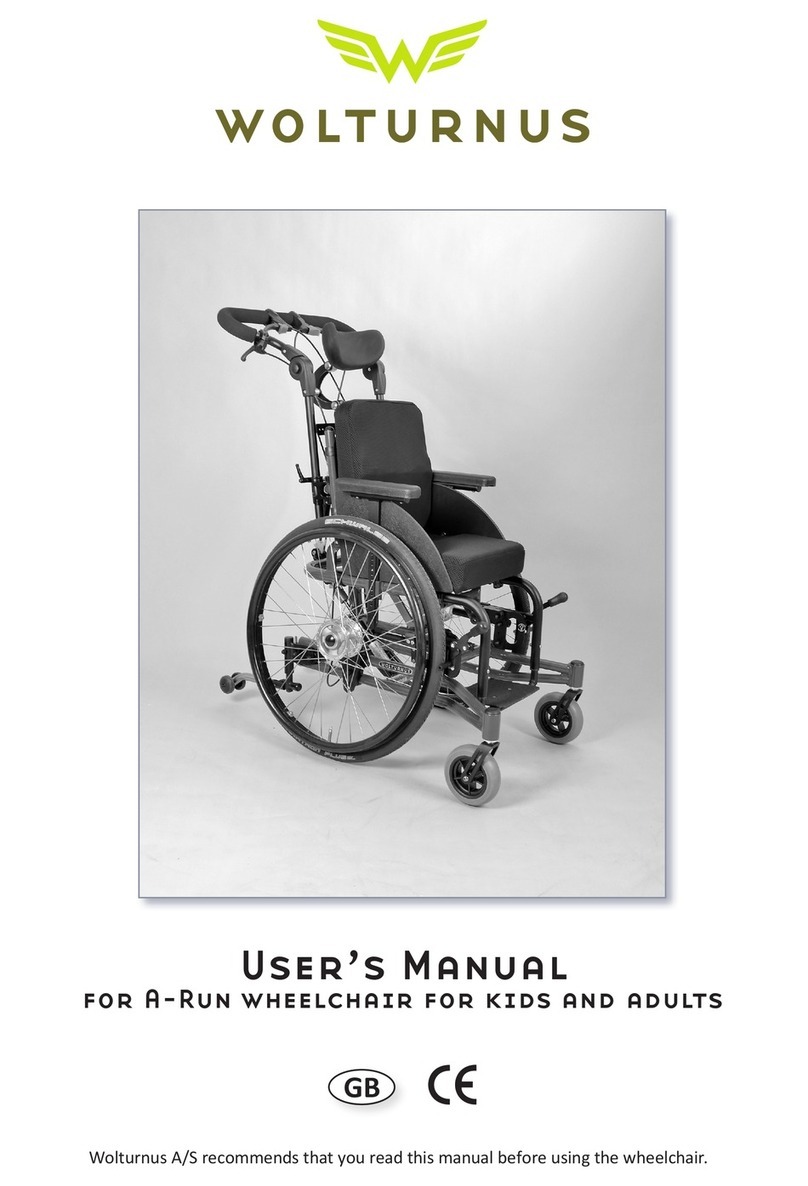

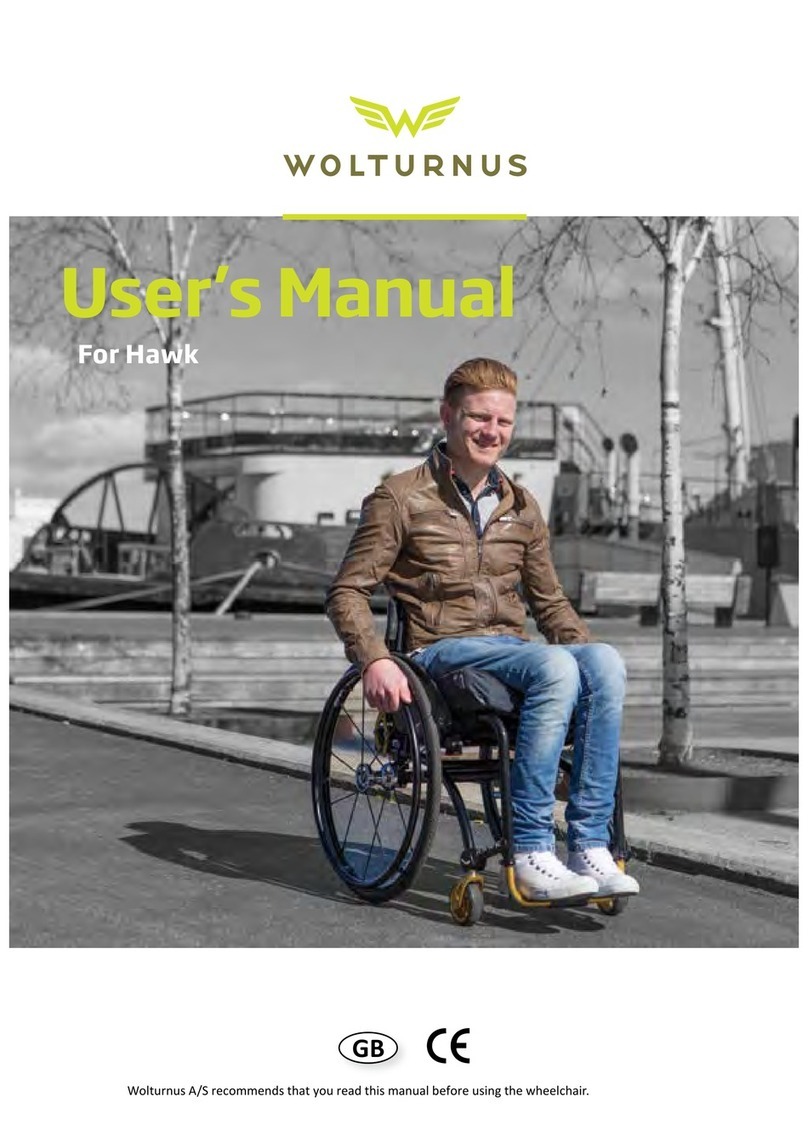

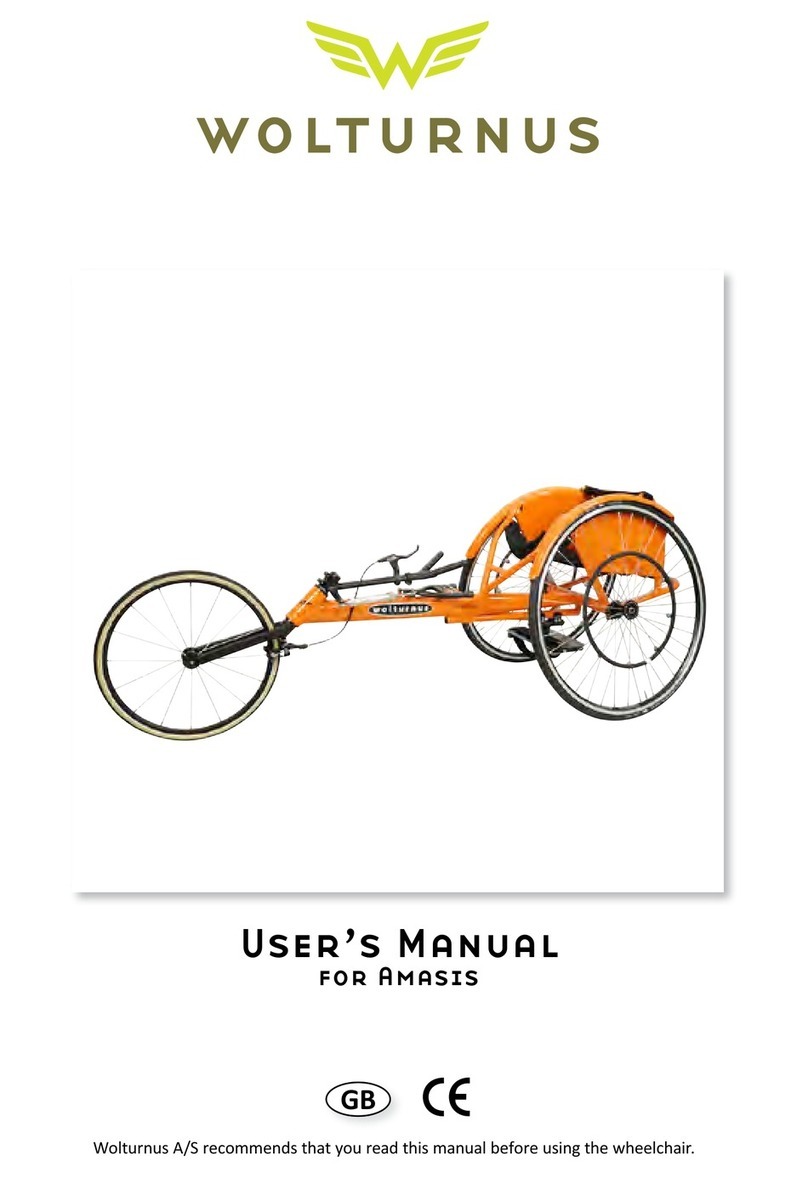

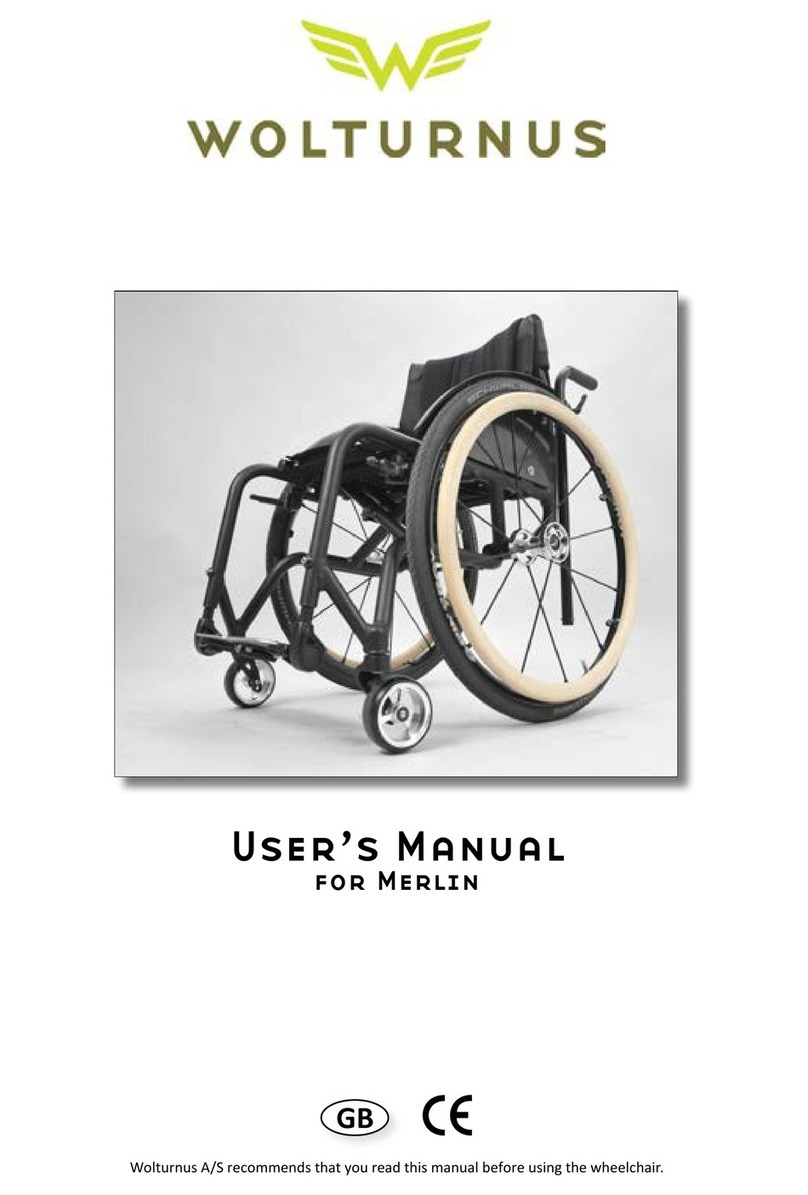

This user manual provides users and helpers with essenal informaon about the design, funcons, use and

maintenance of the Wolturnus W5, Tukan, Gitano, Dalton, Dance wheelchair for adults, throughout the rest of

this manual these models will be described by the wheelchair. The manual contains the informaon necessary

to ensure safe use of the wheelchair. It contains troubleshoong informaon with, where applicable, soluons.

The wheelchair is an easy-propulsion acve wheelchair in high-strength aluminium. The wheelchair design

makes it as easy as possible for the user to operate the chair independently. The wheelchair is custom-built

according to the user’s instrucons. This ensures that the wheelchair precisely meets the individual user’s re-

quirements. Because the back can be folded and both the rear wheel and sideguards removed, the wheelchair

is easy to transport, including in ordinary cars. The wheelchair is ideal for users who want to have an acve

daily life, indoors and outdoors. The amount of adjustability may vary depending on the model and ordered

features.

The instrucons in this manual are essenal for safe and correct use of the wheelchair. Before starng to use

it, it is important that both the user and helper read these instrucons carefully paying special aenon to the

safety instrucons. The informaon provided ensures that the user gets the opmum advantage of the wheel-

chair’s features and funcons. Visually impaired users may obtain this informaon by having another person

read for them. Furthermore, the manual is available on www.wolturnus.dk/en/ where it is possible to enlarge

the text or have the text read up by a suitable computer program. Keep this user manual throughout the lifeme

of the wheelchair: It contains informaon that can answer future quesons and it contains guidelines for adju-

sng and adapng the chair.

This user manual has been produced in accordance with DS EN82079-1 ’Preparaon of instrucons for use -

Structuring, content and presentaon’. It is divided into secons. The heading on each page contains the tle of

the overall secon. The foot of each page displays the page number, year, and site of origin of the user manual.

It also includes the wheelchair model.

1.2. Intended use

The wheelchair is designed for individual mobility, indoors and outdoors. It is only suitable for people who are

unable to walk or have a mobility problem, but have unimpaired sight and cognion. Only equipment that is

specied in this user manual may be used with this wheelchair, and vice versa.

Wolturnus A/S does not guarantee this product if it is used with accessories or products from manufacturers

other than those specied as part of the modular system.

Use of the wheelchair for any purpose other than the aforemenoned will be considered incorrect. In the event

of incorrect use, the user - i.e. not the manufacturer - is liable for resulng damage to persons or property.

The wheelchair may only be used by pracsed users. For personal protecon and in order to ensure that the

wheelchair is used safely and correctly, it is a requirement that the user and helpers receive training and instruc-

on.

The wheelchair can only be used safely if it is used correctly in accordance with the informaon provided in this

user manual. The user bears nal responsibility for accident-free use.

The wheelchair service and repairs may only be

carried out by authorised personnel trained by

Wolturnus A/S. In the event of problems, please

contact Wolturnus A/S

INFORMATION

Risk of injury with incorrect use

To avoid the risk of geng ngers caught in the

rear wheel spokes or wheel locks, and to avoid

the risk of the chair pping, children should not

play with the wheelchair.

WARNING!

1.4 Service

In the event of quesons or problems that cannot be resolved using this user manual, please contact Wolturnus

A/S customer service at (+45) 9671 7170.

Wolturnus A/S strives to provide full assistance to its customers in every respect and thus to ensure total sas-

facon with the wheelchair. Wolturnus A/S contact informaon and a list of service locaons can be found in

secon 13.

In the event that the wheelchair requires repairs at Wolturnus A/S for an extended period of me, a courtesy

wheelchair can be borrowed for that period. Please contact Wolturnus A/S for further informaon.

1.5 CE compliance

The wheelchair meets the requirements of European Commission Direcve 93/42/EEC for medical devices. The

product is classied as Class 1 on the basis of the classicaon criteria for medical devices in accordance with lX

of the direcve. Wolturnus A/S has therefore, as manufacturer with sole liability, made a declaraon of confor-

mity in accordance with appendix Vll of the direcve.

1.6 Liability

Wolturnus A/S’ warranty applies only if the product is used in accordance with the specied circumstances,

purpose and instrucons. The frame is covered by a 5-year warranty. Other parts manufactured by Wolturnus

4 5