SM1111-04E Page 3 of 5 ©Aero-Motive Company Feb-03

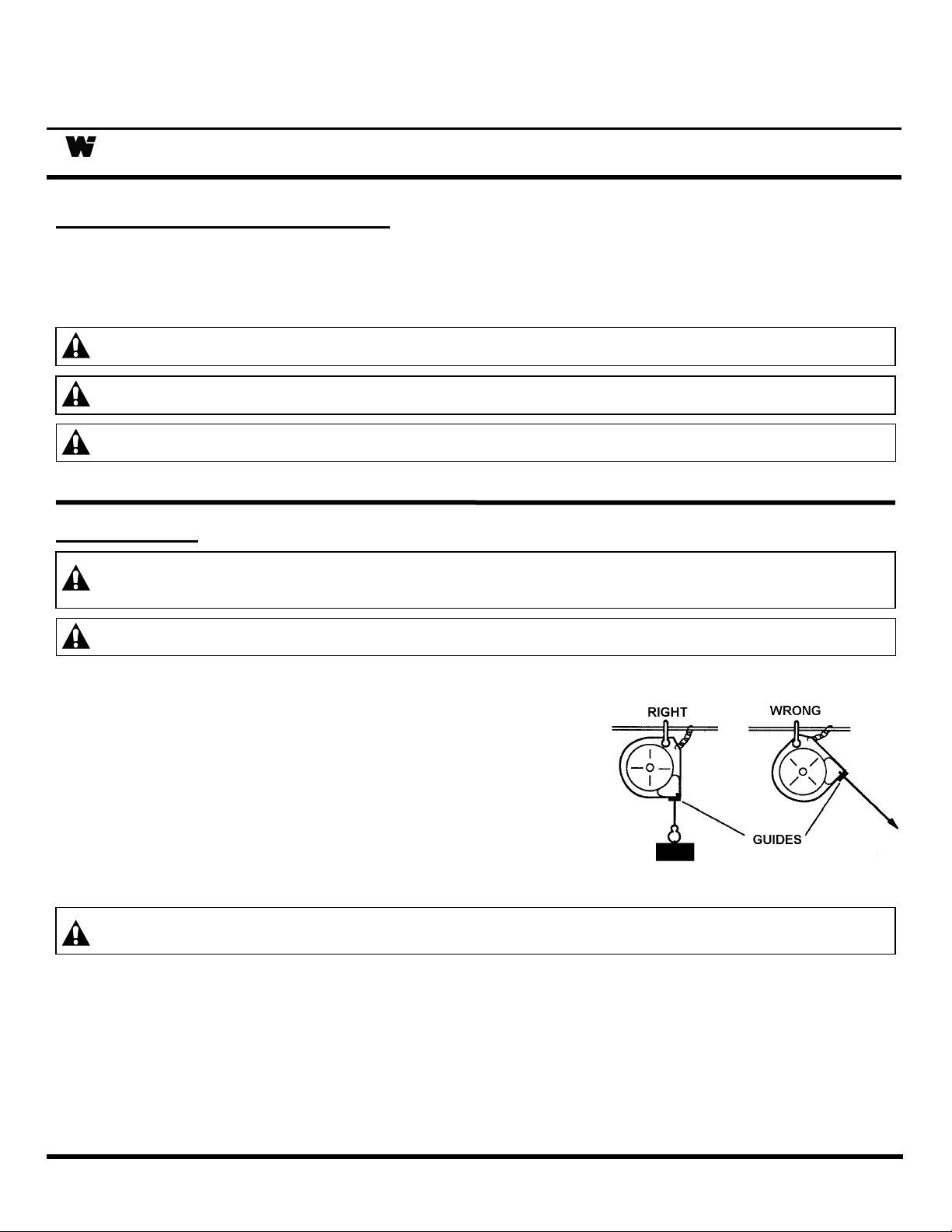

CABLE STOP ADJUSTMENT

NOTE: Moving the cable stop will reduce the active travel distance. If additional cable extension is required,

extension cable assemblies are offered as an accessory.

Cable stop can be moved up along the cable to attain the most desirable working height.

SERVICE

MAIN SPRING REPLACEMENT

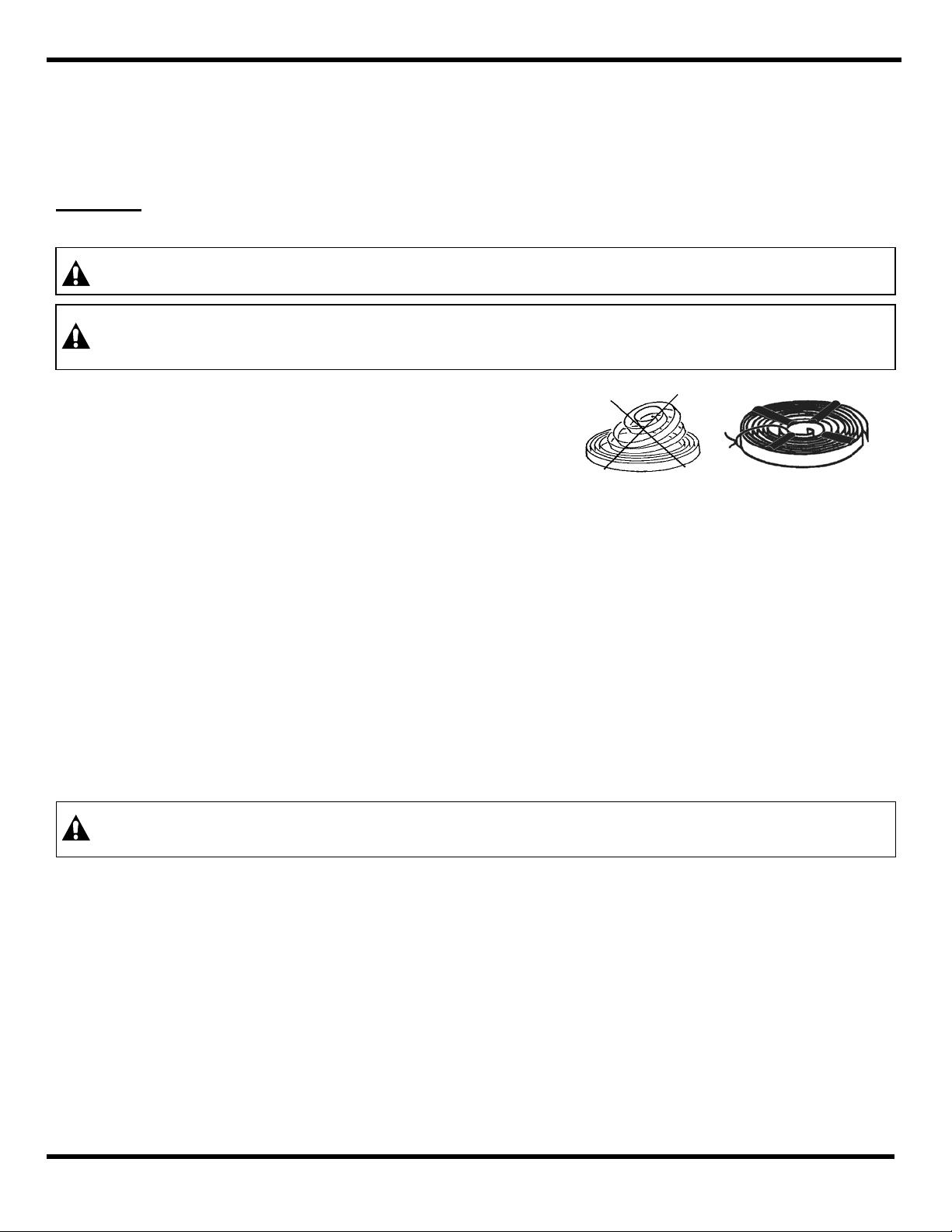

CAUTION: Remove all tension before removing mainspring. Hazards or unsafe practices MAY result

in minor personal injury or product or property damage.

WARNING:

Spring is dangerous. Always wear gloves. Before removing broken spring, weld coils

together at four (4) locations or wrap securely with wire. Hazards or unsafe practices

COULD result in severe personal injury or death.

Remove All tension from main spring (See Spring

Tension Adjustment). Remove cotter pin and then clevis.

Next, remove the retaining ring and the three (3) screws,

also plates and screws. Remove housing. Remove

drum-cover nuts and cover. Carefully remove mainspring

from drum. Hub may come off shaft with spring.

If so, replace hub into new spring while making sure hub engages spring coils. Replace spring in

drum while making sure the spring hook engages with drum outer hook. To reassemble, reverse the

above procedure. Be sure the hub engages the pin on the main shaft when reassembling.

CABLE REPLACEMENT

Whenever a cable shows signs of deterioration, it should be replaced with a new cable. Remove All

tension from main spring (See Spring Tension Adjustment). Remove clevis by removing the cotter pin.

Next, remove the retaining ring and the three (3) screws, also plates and screws. Remove housing.

Remove nut and cable. Replace with new cable while threading it through guide first when reassembling.

RATCHET LOCK REPLACEMENT

Remove All tension from main spring (See Spring Tension Adjustment). Remove clevis by removing the

cotter pin. Next, remove the retaining ring and the three (3) screws, also plates and screws. Remove

retaining ring, washer, and spring lock, and retaining ring. The housing can now be removed. Remove

retaining ring and unclip spring, then remove ratchet lock. To reassemble, reverse the above procedure.

PARTS REPLACEMENT

CAUTION:

Always remove all spring tension (see “Spring Tension Adjustment”) before attempting to

disassemble internal parts. Always remove retractor reel from service. Hazards or unsafe

practices MAY result in minor personal injury or product or property damage.

NOTE: When ordering replacement parts, always include retractor reel model number and serial number.

All parts are replaceable in the field without special tools.

LUBRICATION

All bearings, springs, etc. are permanently lubricated at factory and should require no further lubrication.

MAINTENANCE & INSPECTION

Due to the design, this reel will require little maintenance other than a periodic check of the cable, safety

chain, and hanger for wear. All worn parts or cable should be removed from service and/or replaced at

once.