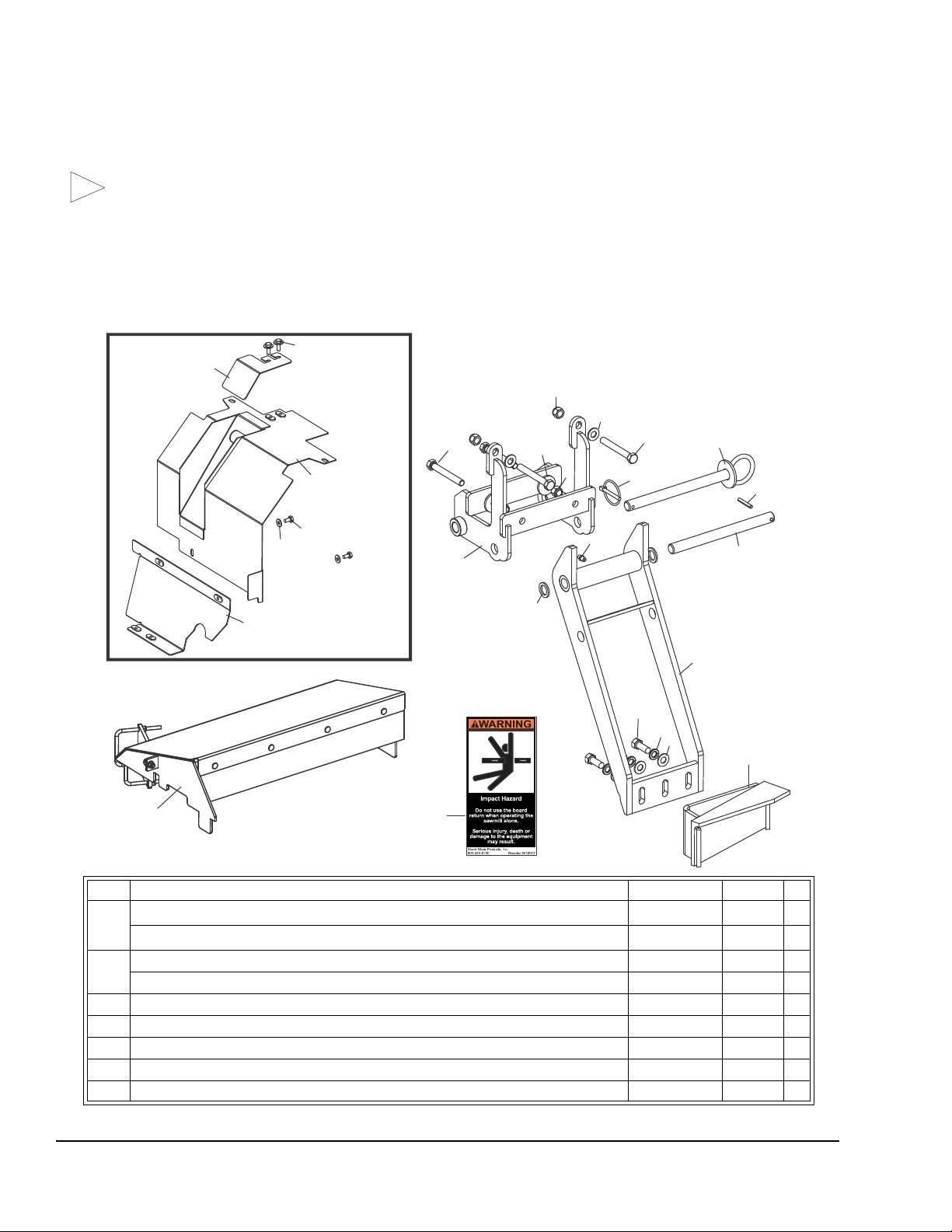

woodmizer LT30 User manual

Other woodmizer Saw manuals

woodmizer

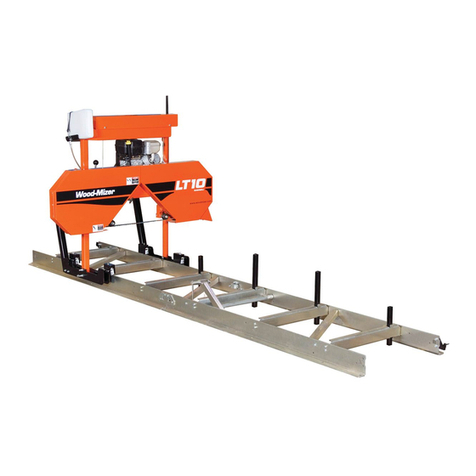

woodmizer LT10 User manual

woodmizer

woodmizer PC200A10 User manual

woodmizer

woodmizer LT30HD Manual instruction

woodmizer

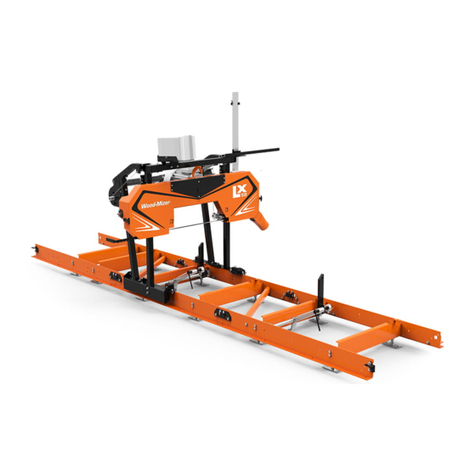

woodmizer LX25 Guide

woodmizer

woodmizer LT15 AL-KO Manual instruction

woodmizer

woodmizer 1992 LT30HD Manual

woodmizer

woodmizer LT30HD Manual instruction

woodmizer

woodmizer Simple Set SSW Guide

woodmizer

woodmizer SVSE11S User manual

woodmizer

woodmizer LT40 Series Manual instruction

woodmizer

woodmizer LX55 Guide

woodmizer

woodmizer LX50 EH7S User manual

woodmizer

woodmizer LT30HD Manual instruction

woodmizer

woodmizer LT15S3 E11S Manual instruction

woodmizer

woodmizer LT15 Guide

woodmizer

woodmizer HR200 User manual

woodmizer

woodmizer LT28 Manual instruction

woodmizer

woodmizer SHR-T Series User manual

woodmizer

woodmizer LT50HD Manual instruction

woodmizer

woodmizer LT15S3 G13 Manual instruction