3

14

TABLE OF CONTENTS

Warranty and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Speed Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Basic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Introduction

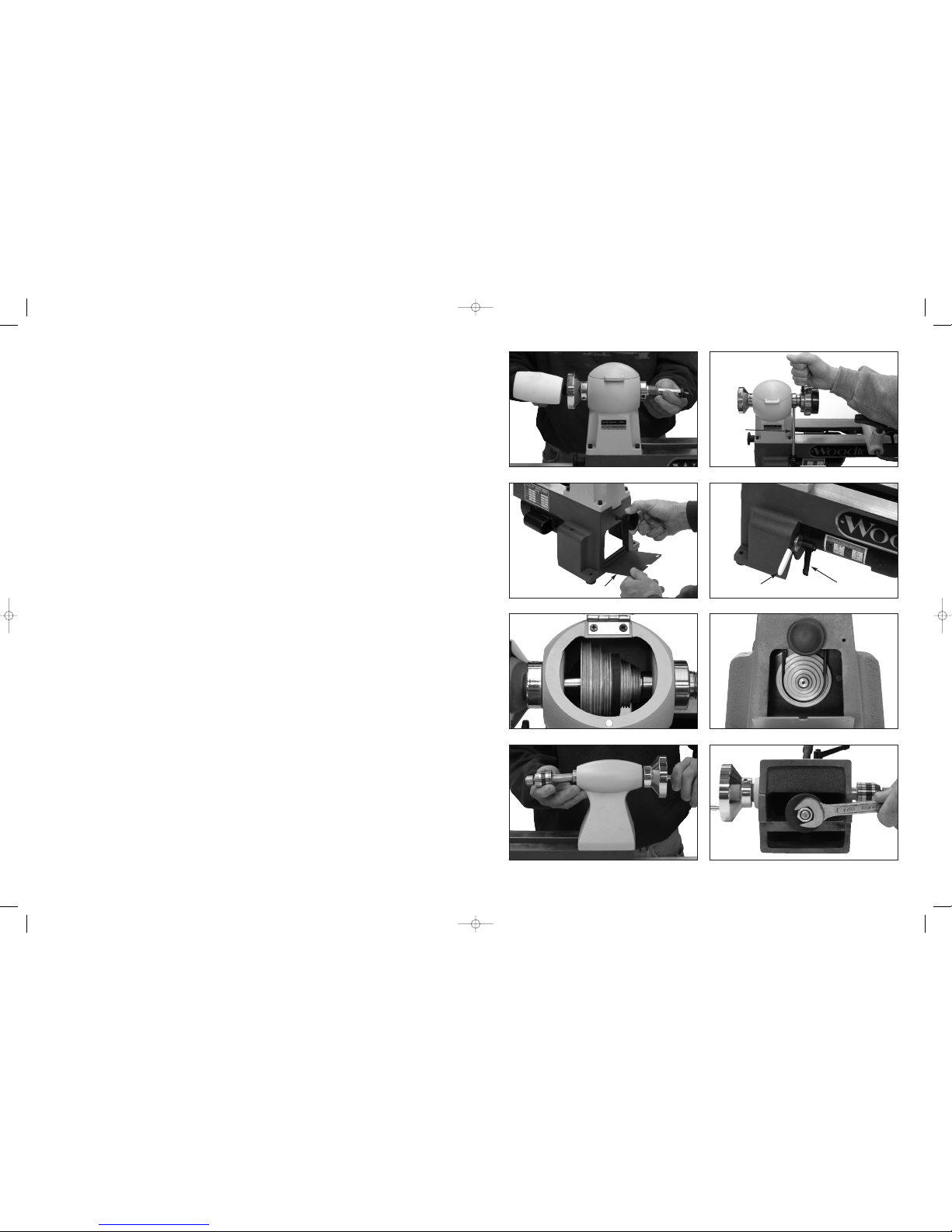

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Headstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Pulley Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Tailstock and Tool Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Operation

Turning Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sharpening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Spindle Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Bowl Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

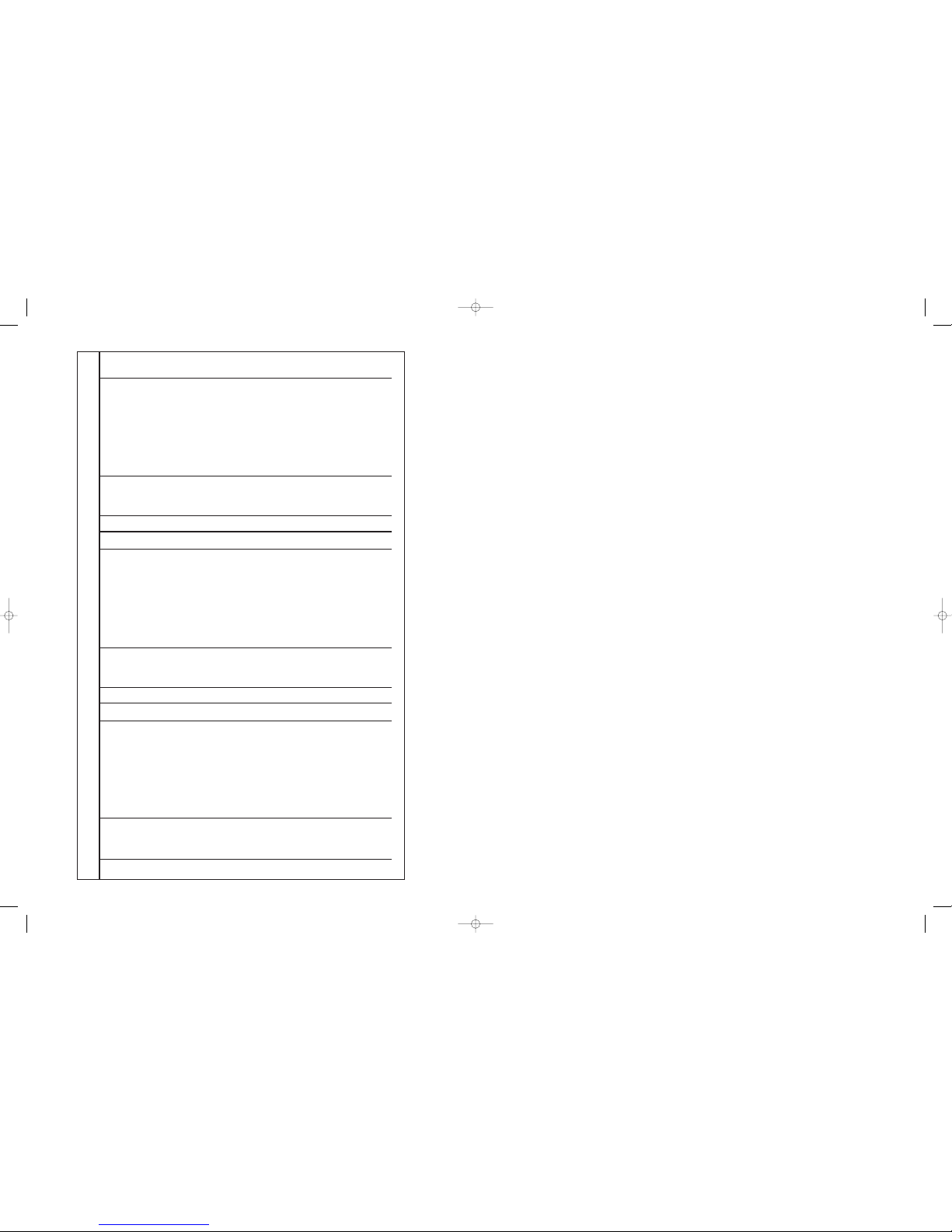

Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

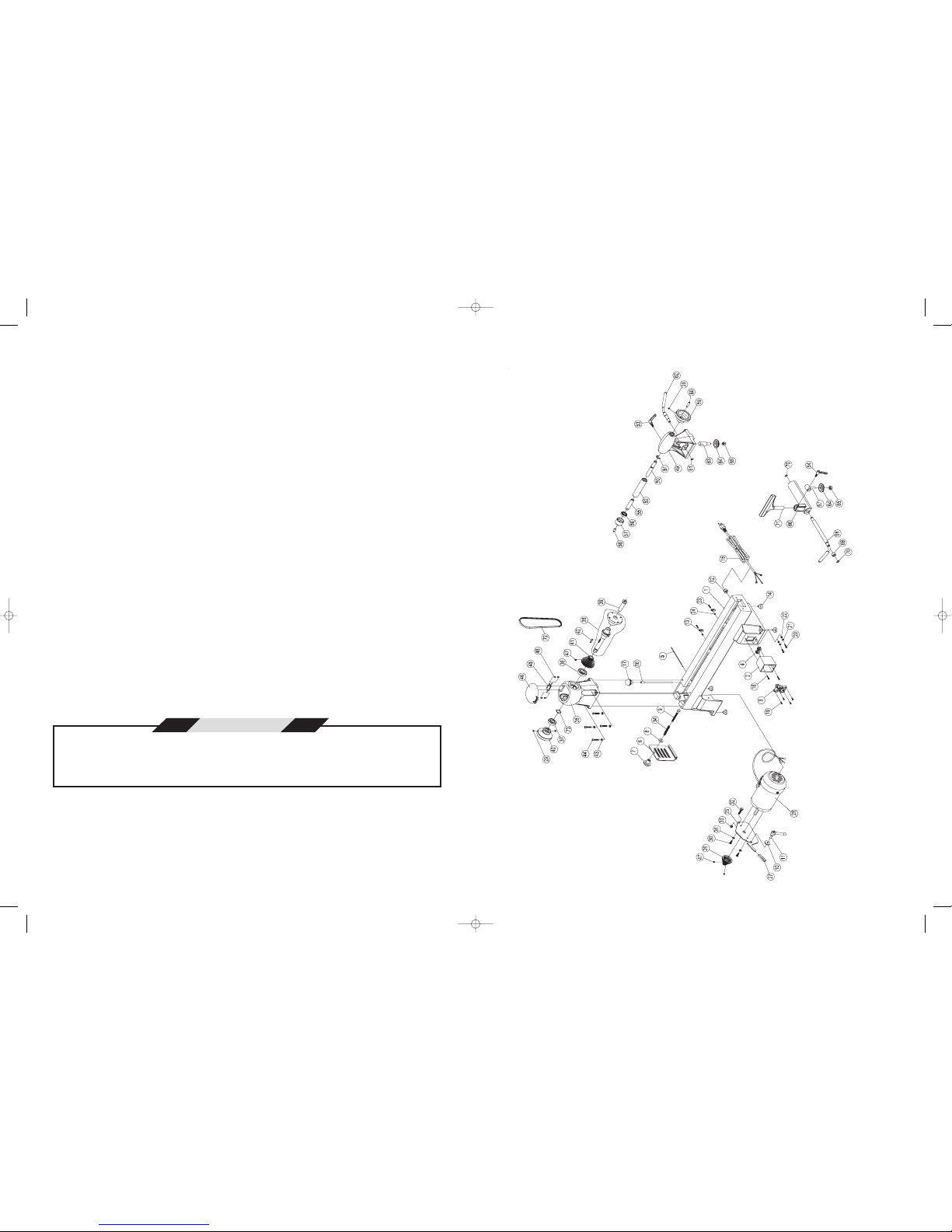

Schematic Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

REF REF REF

NO. PART NO. DESCRIPTION QTY NO. PART NO. DESCRIPTION QTY NO. PART NO. DESCRIPTION QTY

PARTS LIST

1 050763-000 LATHE BED 1

2 050764-000 SWITCH BOX 1

3 937335-000 ON/OFF SWITCH ASSY 1

4 020007-000 GROMMET, 6B3-2 2

5 380412-905 PIN 1

6 172019-000 MOTOR PULLEY COVER 1

7 250603-000 PULLEY COVER KNOB 1

8 006002-056 FLAT WASHER, 8.5x23x2t 1

9 000003-217 HEX CAP SCREW, 1

M8x1.25Px75

10 006002-040 FLAT WASHER, 8x30x3t 1

11 921457-000 MOTOR LOCKING HANDLE, 1

5/16"-18UNCx3/4"L

12 340063-615 GROMMET 1

13 021102-000 WIRE CLIP, ACC-2.5 2

14 250492-615 FOOT PAD 4

15 453011-028 POWER CORD, 1

SJT-18AWG-3C

16 380445-906 SHAFT LOCKING/KNOCKOUT 1

ROD

17 250372-615 KNOB 1

18 001102-208 ROUND HEAD TAPPING 2

SCREW, M4x1.59Px25

19 000302-109 ROUND HEAD SCREW, 2

M4x0.7Px16

20 000303-207 ROUND HEAD SCREW, 2

M5x0.8Px20

21 006502-200 STARWASHER, 2

5.3x10x0.6t(BW-5)

22 008004-200 HEX NUT, M5x0.8P 2

23 000302-205 ROUND HEAD SCREW, 2

M4x0.7Px15

24 008002-200 HEX NUT, M4x0.7P 2

25 171460-902 MOTOR TENSION PLATE 1

26 090116-000 MOTOR PULLEY 1

27 250495-625 HANDLE COVER 1

28 900540-000 MOTOR 1

29 003201-101 SET SCREW, 1/4x20UNCx1/4" 3

30 003001-106 HEX CAP SCREW, 2

1/4x20UNCx5/8"

31 006304-100 SPRING WASHER, 2

6.5x12.8x1.5t

32 003003-206 HEX CAP BOLT, 1

5/16x18UNCx1-1/4"

33 009105-200 LOCK NUT, 5/16"-18UNC 1

34 280117-901 SPRING 1

35 050761-000 HEADSTOCK 1

36 030408-000 BEARING, 6005-2HK 1

37 030407-000 BEARING, 6004-2HK 1

38 921604-000 SPINDLE SHAFT 1

39 921458-000 SPUR CENTER 1

40 240060-906 HEADSTOCK HANDWHEEL 1

41 090115-000 SPINDLE PULLEY 1

42 012003-009 KEY, 5x5x25 1

43 006304-100 SPRING WASHER, 4

6.5x12.8x2.0t

44 003103-104 SOCKET HEAD CAP SCREW, 4

1/4-20UNCx1-1/4"

45 921577-000 HINGE 1

46 050762-000 HEADSTOCK COVER 1

47 000203-102 SET SCREW, M6x1.0Px8 3

48 000401-201 FLAT HEAD SCREW, 4

M4x0.7Px8

49 050765-000 TAILSTOCK 1

50 360369-901 QUILL SCREW 1

51 010208-000 E-RING, ETW-12 1

52 360361-000 TAILSTOCK QUILL 1

53 921556-000 LOCKING HANDLE, 1

5/16"-18UNC-20L

54 921455-000 LOCKING HANDLE, 1

5/16"-18UNC-15L

55 380414-901 LIVE CENTER SHAFT, #2MT 1

56 030112-000 BEARING, 6002ZZ 1

57 380413-901 LIVE CENTER HEAD 1

58 380415-901 LIVE CENTER POINT 1

59 240053-906 TAILSTOCK HANDWHEEL 1

60 380444-906 HANDWHEEL HANDLE 1

61 010206-000 S-RING, ETW-9 1

62 380409-902 TAILSTOCK LOCKING HANDLE 1

63 380408-905 TAILSTOCK EYE BOLT 1

64 160053-901 LOCK PLATE 2

65 008312-200 LOCK NUT, M10x1.5P 2

66 050764-000 TOOL REST BASE 1

67 380411-902 TOOL REST EYE BOLT 1

68 380410-902 LOCKING SHAFT 1

69 160058-000 BUSHING 1

70 010003-000 S-RING, STW-12 2

71 070026-901 TOOL REST 1

72 014313-000 POLY-V BELT, 240J3 1

73 006711-100 WAVY WASHER, WW-20 1

74 570929-000 FACEPLATE, 3-1/8" DIA 1

75 383447-901 SPINDLE ADAPTER, 1

1"-8TPI TO 1-1/4"-8TPI

76 380443-906 SPUR CENTER POINT 1

77 940333-000 MANUAL 1

78 042607-000 GOGGLES 1

79 040005-00 ALLEN KEY, 5MM 1

80 004003-000 ALLEN KEY, 3MM 1