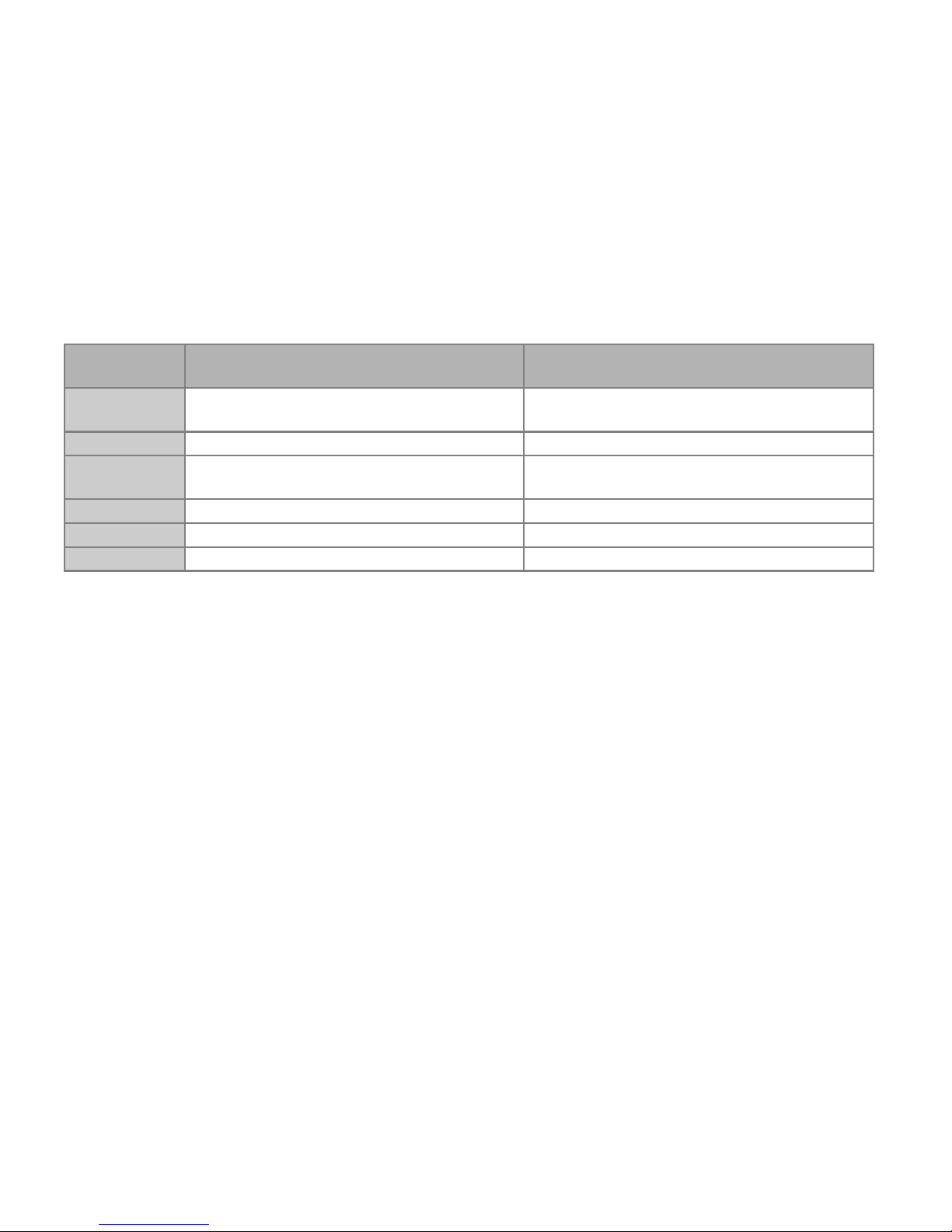

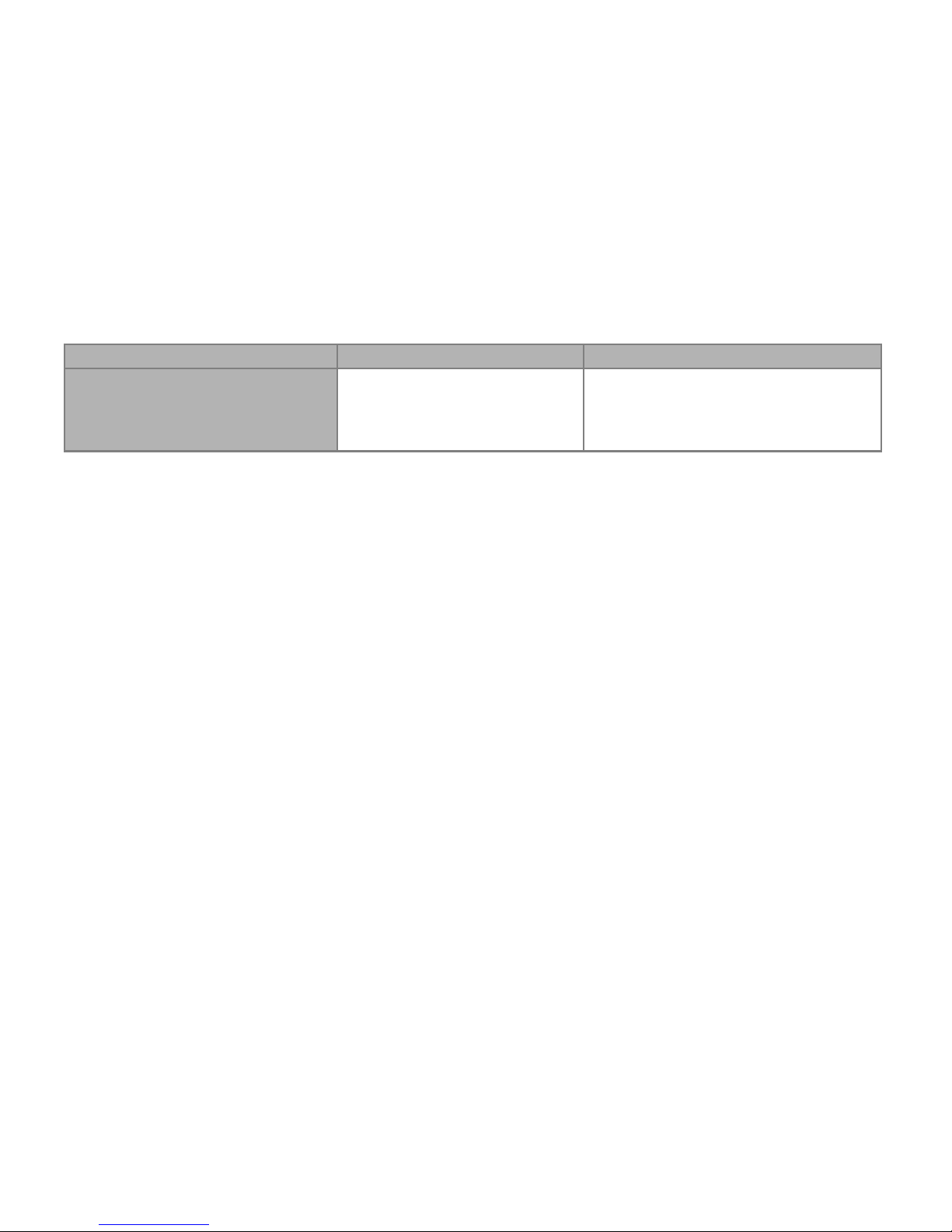

System LED Device Status Potential Error Cause Corrective Action

constant green

The device´s HMI is not operable.

There are no Softkeys shown on the

panel. Instead the panel shows

„Startup“ or just the device type (e.g.

MCA4) without any Softkeys.

The device is starting up. The

protection functions are already

working, but the HMI is still starting up.

If this is not finished after 5 minutes,

the device is probably busy with

handling Ethernet packets (Connector

X100).

Check if the following action makes the device´s HMI

operable:

Plug off the Ethernet (Connector X100). Is the HMI now

operable, there is an error on your Ethernet network (e.g. an

Ethernet storm). Please check your network traffic.

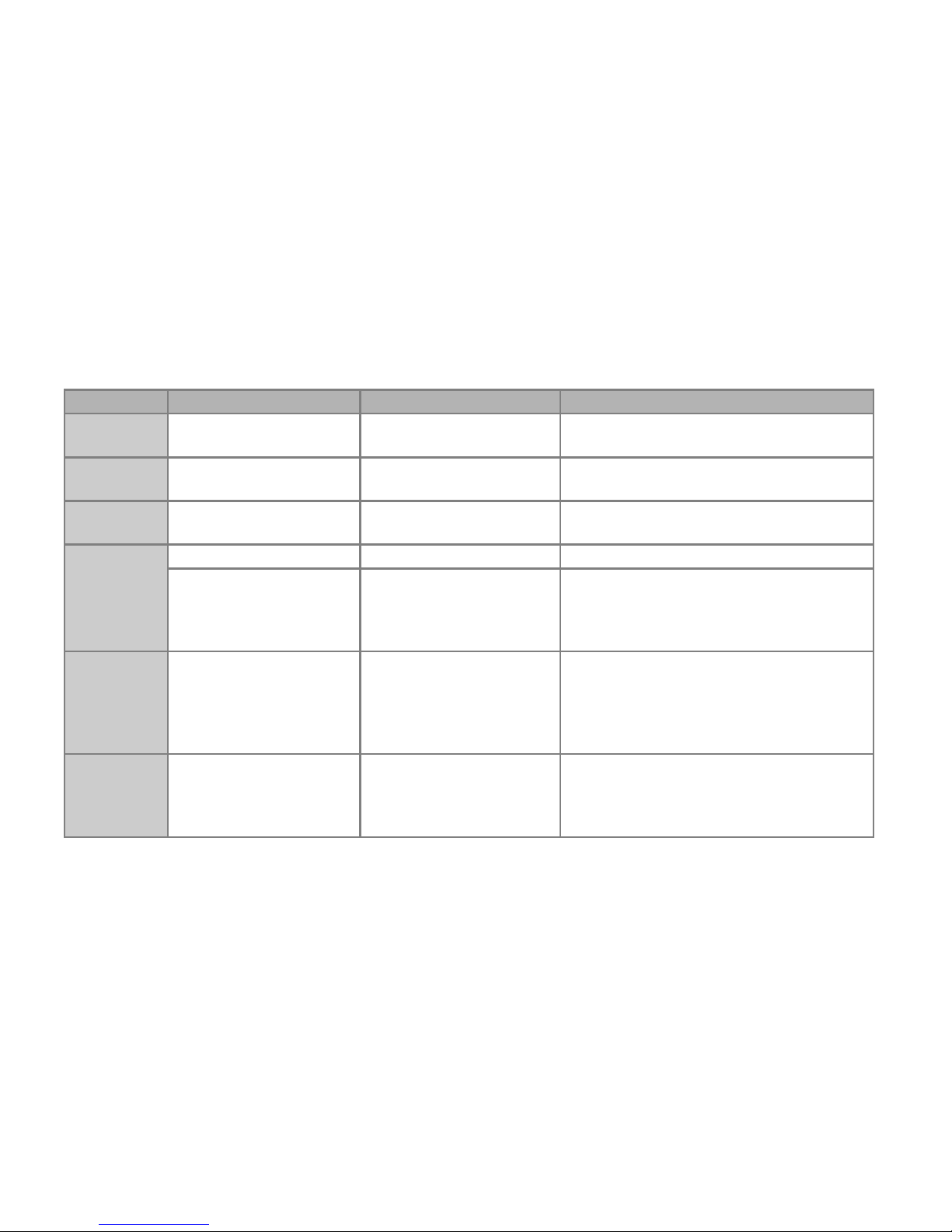

The HMI is not operable. A normal

page of the HMI is visible: Either

there are Softkeys visible or the LED

status page is being displayed.

The device is busy with handling

Ethernet packets (Connector X100).

The protection functions are working.

Plug off the Ethernet (Connector X100). Is the HMI now

operable, there is an error on your Ethernet network (e.g. an

Ethernet storm). Please check your network traffic.

Should this action not change the device´s behavior, please

read the next entry of this table.

The HMI is not operable. A normal

page of the HMI is visible: Either

there are Softkeys visible or the LED

status page is being displayed. There

is no Ethernet connector (Connector

X100).

Some of the device´s system parts are

not working. The protection functions

are working.

Leave the device connected to the supply voltage. Get in

contact with our service-team. You will be supplied with a tool

for error analysis.

HighPROTEC Troubleshooting Guide DOK-HB-TSE Rev. B 6