3

following way: move the control handle (G117) to the LOWER position, then move the draw-bar up and

down several times.

4.3 DAILY CHECK AND MAINTENANCE

Daily check of the pallet truck can limit wear as much as possible. Special attention should be paid to the

wheels, and axles, as thread, rags, etc. may block the wheels. The forks should be unloaded and lowered

in the lowest position when the job is over.

4.4 LUBRICATION

All bearings and shafts are provided with long-life grease at the factory. You should only need to provide

with long-life grease at monthly intervals or after each time the truck is cleaned thoroughly to the lubrication

points.

5 GUIDE TO SAFETY OPERATION

5.1 Operator should read all warning signs and instructions here and on the pallet truck before using this

truck.

5.2 Do not use on sloping ground.

5.3 Do not operate a pallet truck unless you are familiar with it and have been trained or authorized to do so.

5.4 Do not operate a pallet truck unless you have checked its condition. Give special attention to the wheels

and rollers, the draw-bar unit, the fork unit, the lever plate, etc..

5.5 To pull the truck, always move the control handle into the drive position. This makes the draw-bar easier

to move and depressurizes the pump section of the hydraulics. This preserves the hydraulic seals and

the valve components. A long service life can be expected.

5.6 Do not take up any people on the pallet truck.

5.7 The operator should use gloves for protection.

5.8 When the goods have been transported, all people should be away from the forks for 600mm.

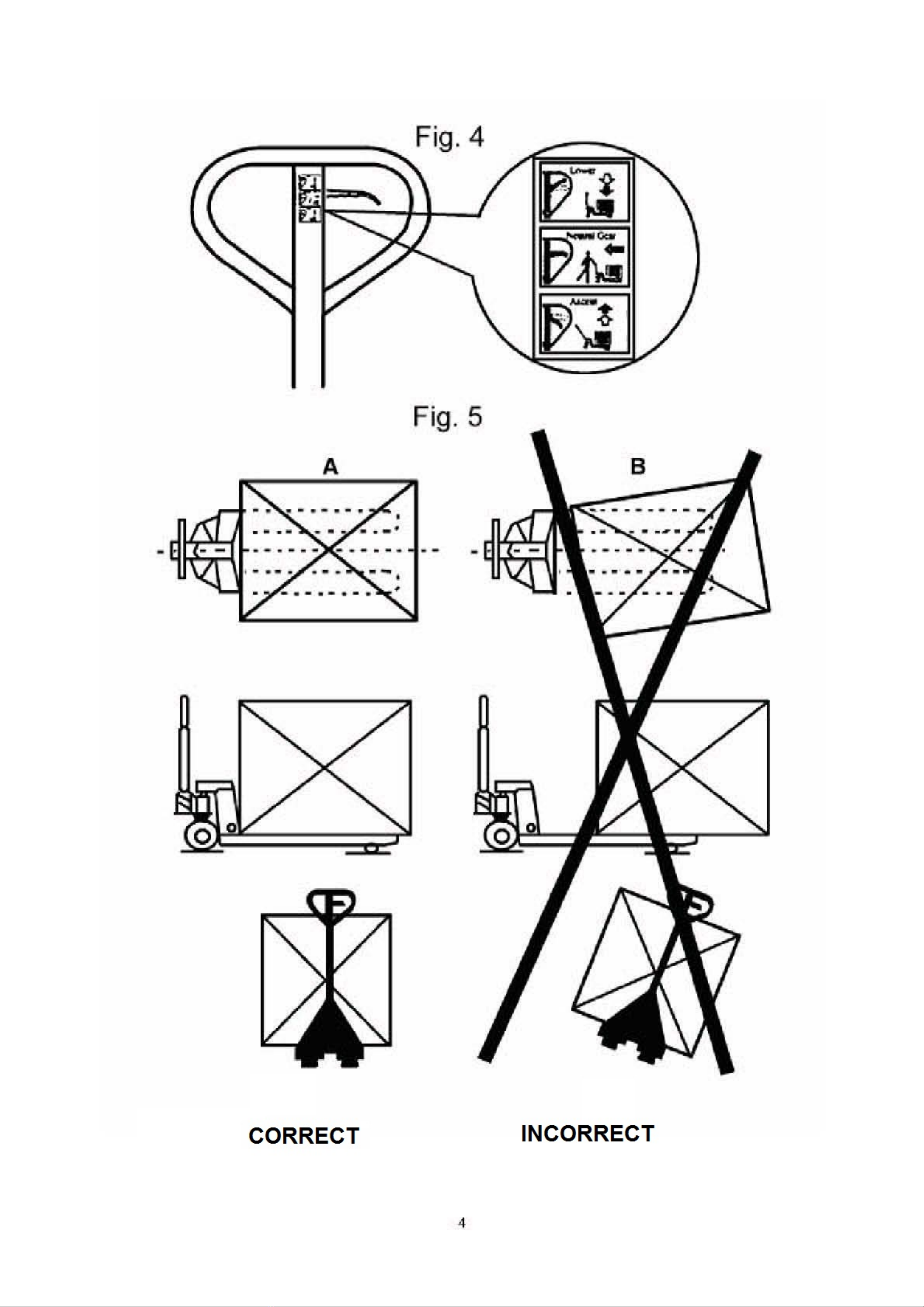

5.9 Do not load goods like fig. 5IB or load over maximum capacity.

6. TROUBLESHOOTING

No. Trouble Cause Fixing Methods

1 Forks won't raise

to max. height. -Not enough hydraulic oil. -Add hydraulic oil.

2 Forks won’t raise. -No hydraulic oil.

- The oil has impurities.

- The nut (G104) is too high keeping the pumping

valve open.

- Air has entered the hydraulic oil.

- Add hydraulic oil.

- Change the oil.

- Adjust the nut (G104) or

screw (318) see step 3.4

- Expel the air (see step 4.2)

3 Forks won’t lower -The piston rod(328) or pump((322) is deformed

resulting from partial loading slanting to one side or

over-loading.

-The fork was kept in the high position for a long time

with piston rod bared resulting in rusting and

jamming of the rod.

-The adjusting nut (G104) or screw (318) is not in the

correct position.

-Replace the piston rod (328)

or pump (322).

- Keep the fork in the lowest

position when not using and

lubricate the rod.

-Adjust the nut (G104) or screw

(318) (see item 3.3).

4 Leaks -Sealing parts worn or damaged.

- Some parts are cracked or worn. -Replace parts with new ones.

5 The fork descends

without the

release valve

working.

- Impurities in the oil are causing the release valve to

not close tightly.

- Some parts of the hydraulic system are cracked or

bored

- Air has entered the hydraulic oil.

- Sealing parts are worn or damaged.

- The adjusting nut (G104) or screw (318) are not in

the correct position.

- Replace with new oil.

- Inspect and replace the bad

parts.

- Expel the air (see step 4.2).

- Replace parts with new ones.

- Adjust the nut (G104) or

screw (318) see step 3.2.

NOTE: DO NOT ATTEMPT TO REPAIR THE PALLET TRUCK UNLESS YOU ARE TRAINED AND AUTHORIZED TO

DO SO.