4. Test of hand pallet truck

4.1 After the truck is assembled, try to pump the hand grip and operate

different positions of control handle knob (10) to examine the lifting, free

position and dropping and check that whether the different positions are

normal or not. See fig 5.

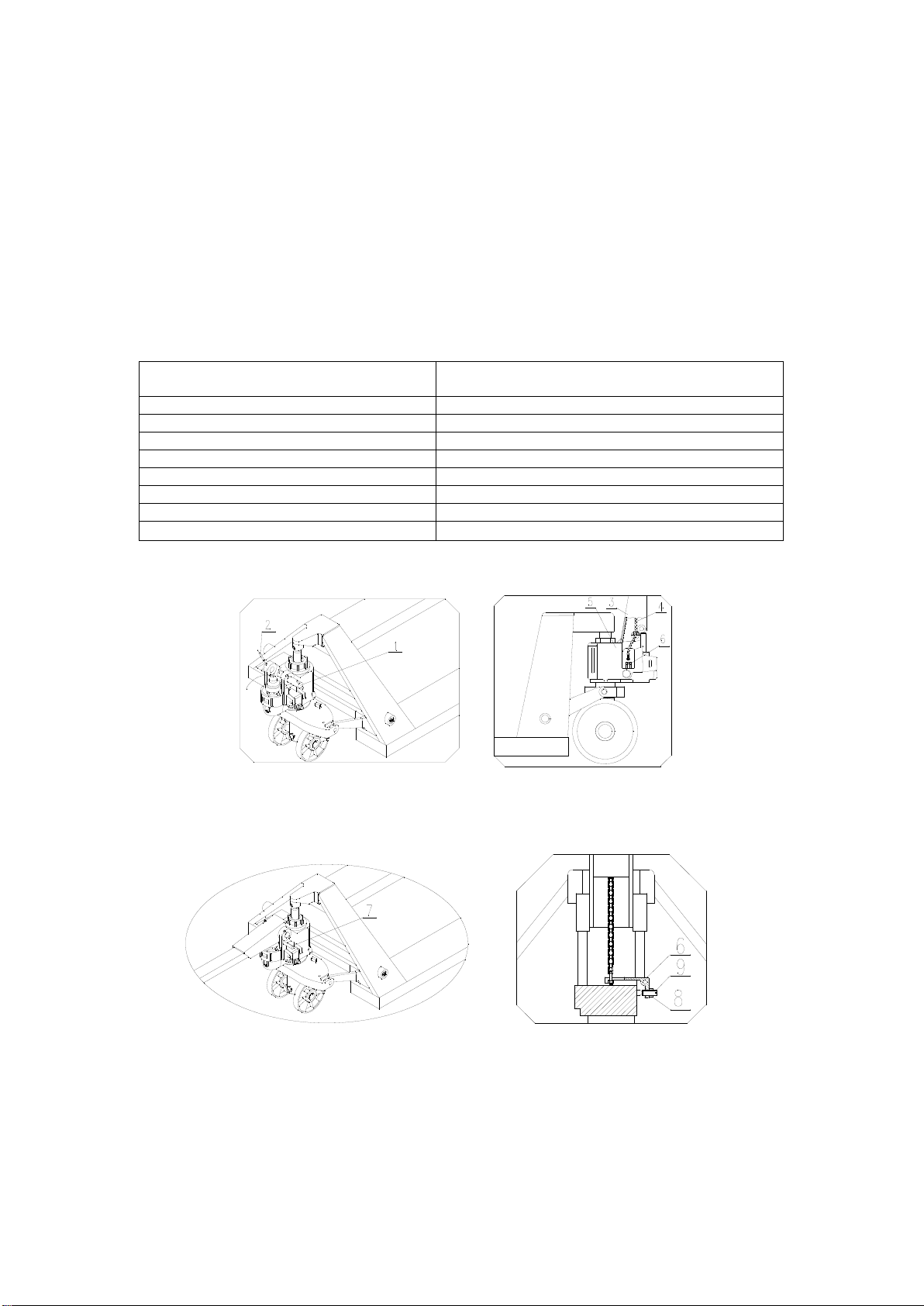

4.2 The screw (9) in fig 4 is used to adjust the truck situation. When the truck

body drops immediately after it is lifted, you should turn the screw (9)

a little counter-clockwise. And then try the truck again until truck body

could lift normally. If the truck body won’t drop after it is lifted, you should

turn the screw (9) a little clockwise. Then try to operate truck again until

the truck body could drop normally. The external hexagon nut (8) at screw

(9)

plays the locking function in the truck. So you should undo the external hexagon nut (10) before

adjustment and screw down the nut (8) after you finish the adjustment.

5. Operation Manual

5.1 Before operation of the hand pallet truck please make sure that whether the cargo

weight exceeds the rated load or not.

5.2 The cargo loading type is shown as fig 6.

5.3 See fig 5, when hand knob (10) is placed on the lift position, the truck will be in a

state of lift. At this time, if you pump the hand grip, the truck will be lifted.

5.4 See fig 5, when hand knob (10) is placed on the free position, the truck will travel.

At this time, if you pump the hand grip, the truck will neither lift nor drop.

Then, you can use the truck to move the cargo.

5.5 See fig 5, when the hand knob (10) is placed on

the drop position, truck forks will drop. At this time, the truck forks will drop

automatically.

5.6 See fig 5, when the hand knob (12) is placed blow, the truck will be in a state of

free walking.

5.7 See fig 5, when the hand knob (12) is placed above, the truck will be in a state of

brake.

5.8 See fig 5, hand knob (11) is used for release brake.

6. Points for attention and safety norms.

6.1 The operator should put on proper work clothes, safety shoes and gloves during the operation of the hand

pallet truck.

6.2 When the hand pallet trucks are transported by truck, they should be locked in order to prevent the trucks

from moving.

6.3 The wheels, bearings and bushings of the truck are wearing parts. Please change them according to

situation.

6.4 Do not park the truck on a slope or in emergency passages.

6.5 When the hand pallet truck is used on a slope, the operator should operate the pallet truck carefully to

avoid tipping.

6.6 When the hand pallet truck is not in use, the forks should be lowered to the lowest position.

6.7 Do not stop the truck on the slope.

6.8 Do not park the truck at places where will block the traffic or is inconvenient for work.

6.9 Do not use the truck in rainy environment.

6.10 The operator should not sit or stand on the hand pallet truck to operate the truck.

6.11 Do not make turns on a slope.

6.12 Do not pile the cargo too high in order to prevent the goods from falling down or overturning of the truck.

6.13 Do not use the hand pallet truck to carry people.

6.14 Untrained personnel are not allowed to stand around the operation area in order to avoid injury caused by

sudden malfunction.

6.15 Before the hand pallet truck is pushed into the elevator, the operator shall make sure that the elevator can

bear the total load of hand pallet truck and cargo as well as the total weight of the operator and other

personnel in the elevator. When entering the elevator, people should let the load enter first and not

operator. When the load or hand pallet truck enters or leaves the elevator, other personnel should not stay

in the elevator.

6.16 The hand pallet truck should be stored in a dry and ventilated environment.

6.17 When the cargo weight exceeds 2500kg/5500lbs, please operate the truck by two persons together for

labor-saving.

7. Inspection before use

Fig. 6