Assembly of Dryer

3730 E. Southern Avenue, Phoenix, AZ 85040 USA

800-778-8779 Workhorseproducts.com 4

Infeed

Oueed

Conveyor Belt

Front Pulley

Rear Pulley

Belt Tracking

Adjust

Exhaust

Convecon System

Panel Heang Elements

Control Box

Underneath the top panel there are three infrared radiant panel heang elements that are controlled by the tablet

controller. They can cure plassol, water-based ink, and any evaporave cured ink. They are capable of heang up

and cooling down within seconds.

Most of the machine’s electrical components are located within the control box. This box is easily accessible for any

necessary maintenance.

Used to raise and lower the heang elements to adjust heat distance to the garment. To raise the element turn the

crank handle clockwise. Turn the crank handle counterclockwise to lower the element.

The exhaust is used to release heat. Use the push pin handle next to the exhaust to control the amount of heat re-

leased.

Filters the incoming air and needs to be cleaned whenever it becomes lled.

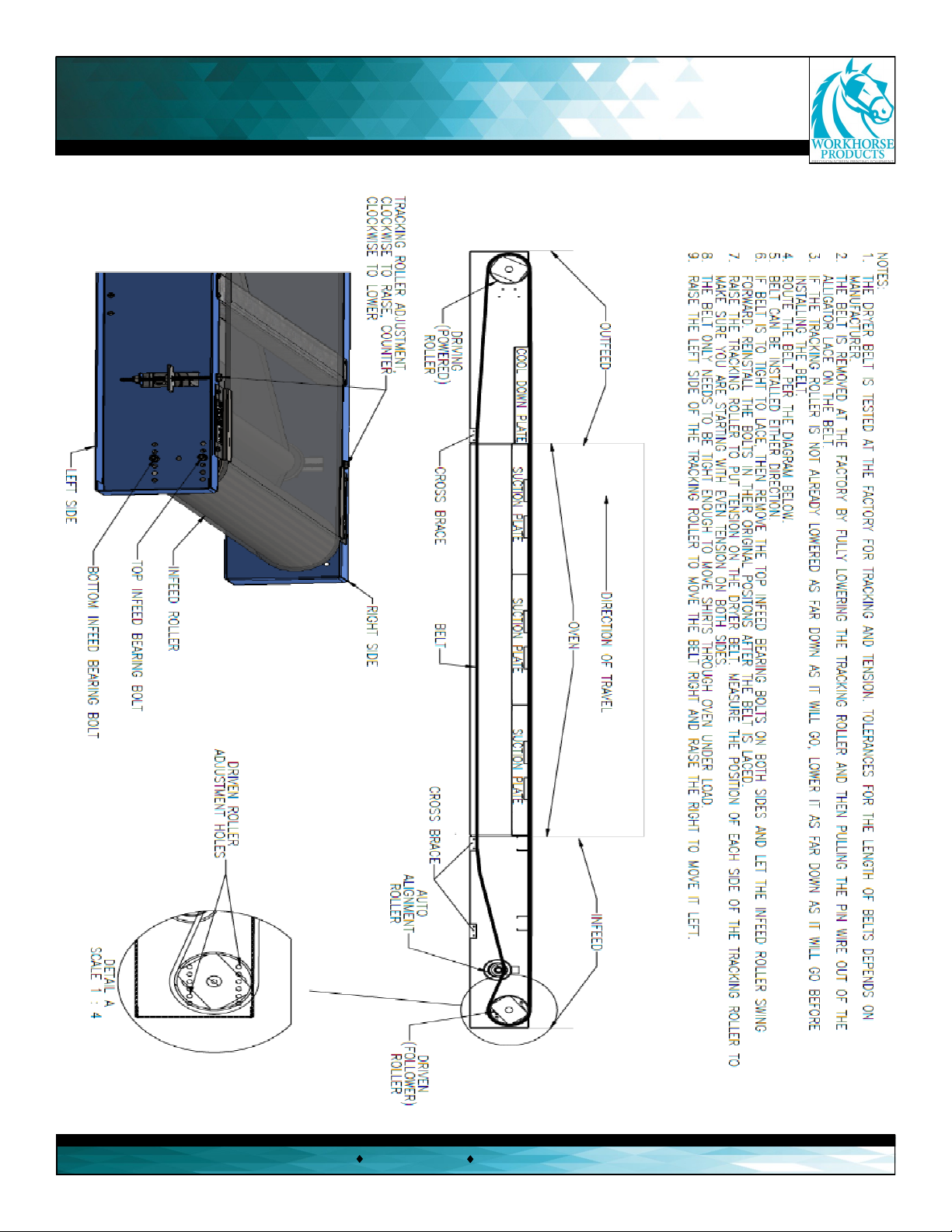

The conveyor belt is created of Teon coated ber glass and is placed on a self-aligning belt tracking system. The

belt is designed to withstand heat, but be sure the belt is always moving when the Powerhouse II is operang

above 300 degrees.

Used for tracking the belt and keeping the belt on the pulley. If the belt moves to the side, use the belt tracking

adjust to center it.

The pulleys are created for precise rolling at an even center.

The tablet controller is the main control system for the Powerhouse Series II. The tablet programs the temperature,

belt speed, warm up, cool down, power consumpon, create presets, access the owner’s portal, and contacts

Workhorse technical support if ever needed.

A precisely designed air system to ulize and release heat within the dryer.

Where the garments are placed to start the curing process.

Where the garments exit the curing process. They land on a cool down table and eventually run o the belt.

Crank Handle

Filtered Intake

Tablet Controller

Panel Heang

Elements

Control Box

Crank Handle

Exhaust

Filtered Intake

Conveyor Belt

Belt Tracking

Adjust

Pulley

Tablet

Controller

Convecon

System

Infeed

Oueed

E-Stop