2

20230701

Thank you for purchasing this Wrekin Water Softener. We are sure this will provide you with many

years of trouble free service. This guide is designed to help you plan, install and commission your

softener correctly so that you get the best out of the machines capability

PLANNING YOUR INSTALLATION

The installation schematic found later in this guide covers all the aspects to assist you with the

correct installation of the softener and covers the main points you need to consider during the

planning stage of your installation (FIG 1)

Check that you have only one rising main and that you have allowed space to access the unit for

possible future maintenance and salt replenishment.

Unless you are replacing an existing water softener, this installation will require you to carry out

plumbing work and may require an electrical outlet to be fitted near the softener. You should only

attempt this if you have the necessary skills

POSITIONING THE SOFTENER

Where possible the softener should be placed close to the rising main. Allowances should be

made to take hard water take off points for untreated drinking water and/or outside taps if required.

Ensure that the drain and overflows will not freeze or reach temperatures higher than 40°C. If the

softener is to be placed inside a cupboard ensure that the base has adequate support. If you are

fitting in a loft space, then the softener should be placed inside a secondary tank/container with its

own overflow fitted at least 3/4in in size. This overflow on the tank must be positioned lower than

the overflow located on the softener. A tank size capable of holding 100 litres would be preferable

if space allows. If installation is to be outside, then this must be contained in a well, insulated

cabinet containing at least 2”of High Grade insulation on all sides and any other steps taken to

avoid freezing

SINGLE CHECK VALVE.

A suitable check valve should be fitted on the supply to the softener. This can be purchased

separately or will be included in the optional fixing kit supplied with the machine.

WATER PRESSURE TEST

It is important to test the water pressure. High and low water pressure can result in either damage

to or failure of the softener. Although the softener is tested to a pressure of 8 Bar (120psi), we

recommend fitting a pressure limiter should your daytime pressure exceed 5bar (70psi). A 5 Bar

PRV can be purchased separately. The minimum working pressure is 1.4bar (20psi). Please note

that partially closing the stop cock will not reduce maximum pressure, it will just reduce flow.

WASTE PIPE CONNECTION

The waste, or Drain pipe should be run to an up stand with a 20mm air gap or to an outside drain

or gully. Softened water waste will have no adverse effect on septic tanks. Should you need to

extend the drain hose this can be done by connecting to 15mm copper tube to a maximum run of

8mtrs with a daytime pressure of 40psi and can be run uphill to a maximum of 1m per 40psi of

daytime pressure Ensure that the drain hose is not kinked or obstructed in any way as this will

lead to an overflow of the softener. A plumbing out kit, with its own Non-Return Valve that can be

attached to a 32mm or 40mm waste pipe to assist in the drain connection can be purchased

separately if required

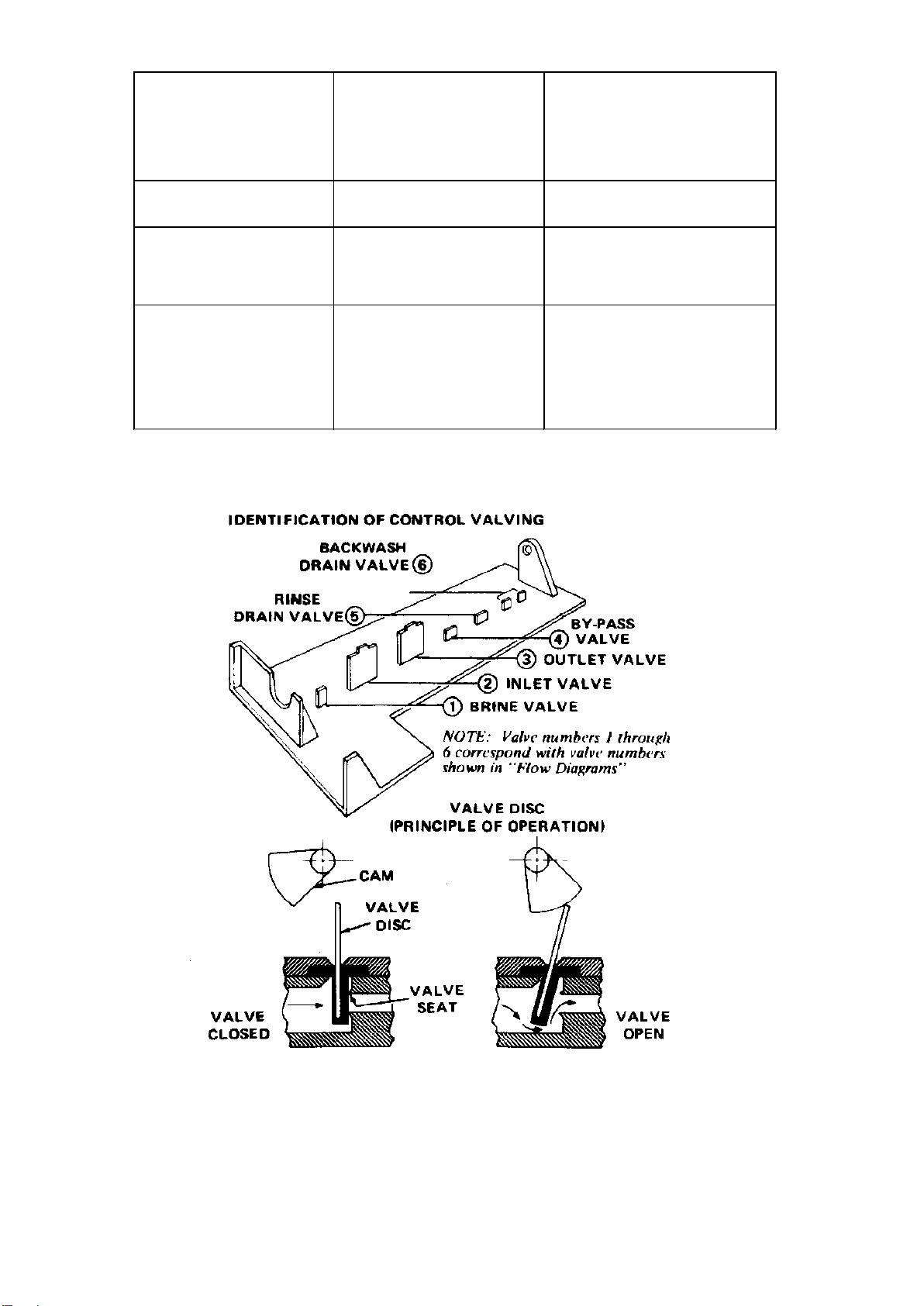

Now you can commence the installations of the valves. Before starting, ensure that you have

turned off the water supply at the main stop cock