www.wto-tools.comB80000-0 ENG4

1 Safety

1.1 General

Description

The following instructions should enable the person responsible for the product and the

person who actually uses the equipment to anticipate and avoid operational hazards.

The person responsible for the product must ensure that all users understand these

instructions and adhere to them.

Generalities

When operating and using our DTH, observe the safety regulations of the regional associations

and the safety laws and guidelines of the respective state and/or the European Union.

Above such regulations, observe the safety instructions of the manufacturer of your machine

tool.

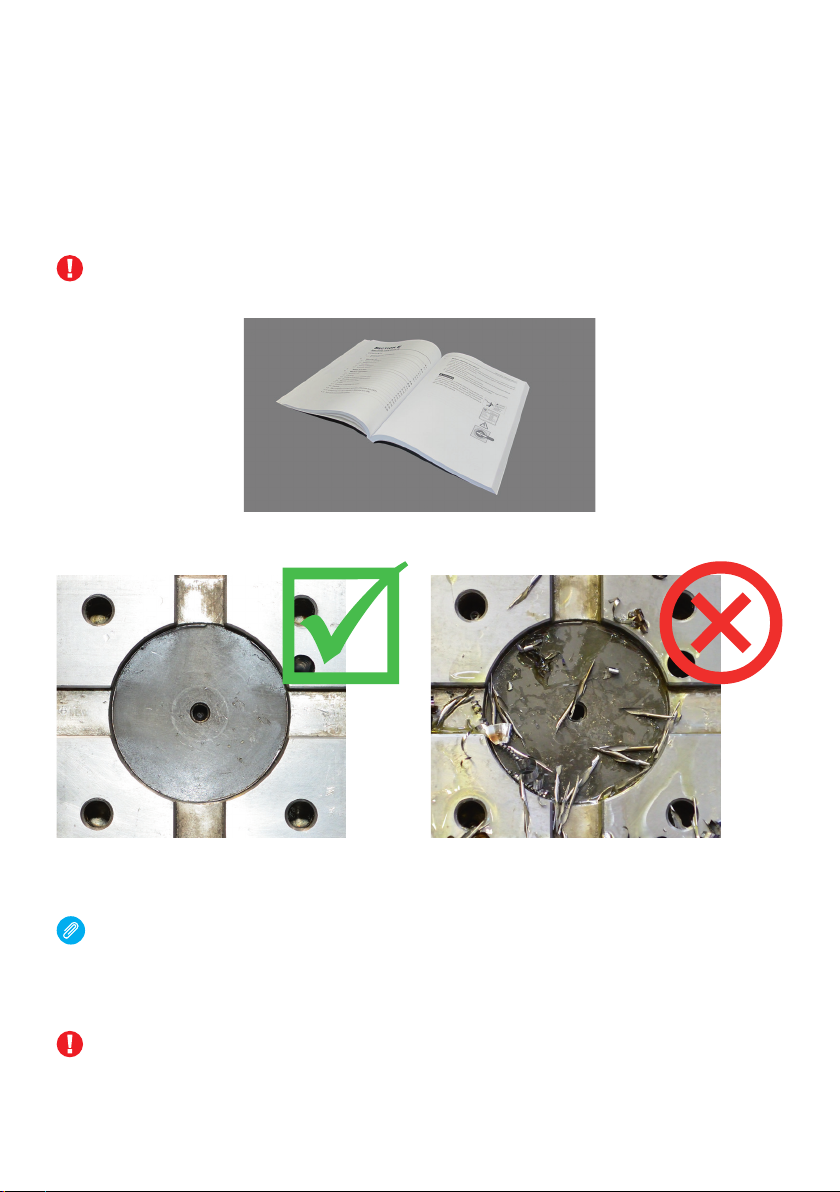

About warning messages

Warning messages are an essential part of product safety. They appear wherever hazards or

hazardous situations can occur.

For user safety, all safety instructions and safety messages shall be strictly observed and fol-

lowed. Therefore, the manual must always be available to all product users.

DANGER, WARING, CAUTION an NOTICE are standardized signal words for identifying levels

of hazards and risks related to personal injury and property damage. For your safety it is

important to read and fully understand the table below with the different signal words and

their definitions. Supplementary safety information symbols may be placed within a warning

message as well as supplementary information.

DANGER

WARNING

CAUTION

NOTICE

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation or an unintended use

which, if not avoided, could result in death or serious injury

Indicates a potentially hazardous situation or an unintended use which, if

not avoided, may result in minor or moderate injury.

Important information which must be adhered to in practice as it

enables the product to be used in a technically correct and efficient

manner.