Contents

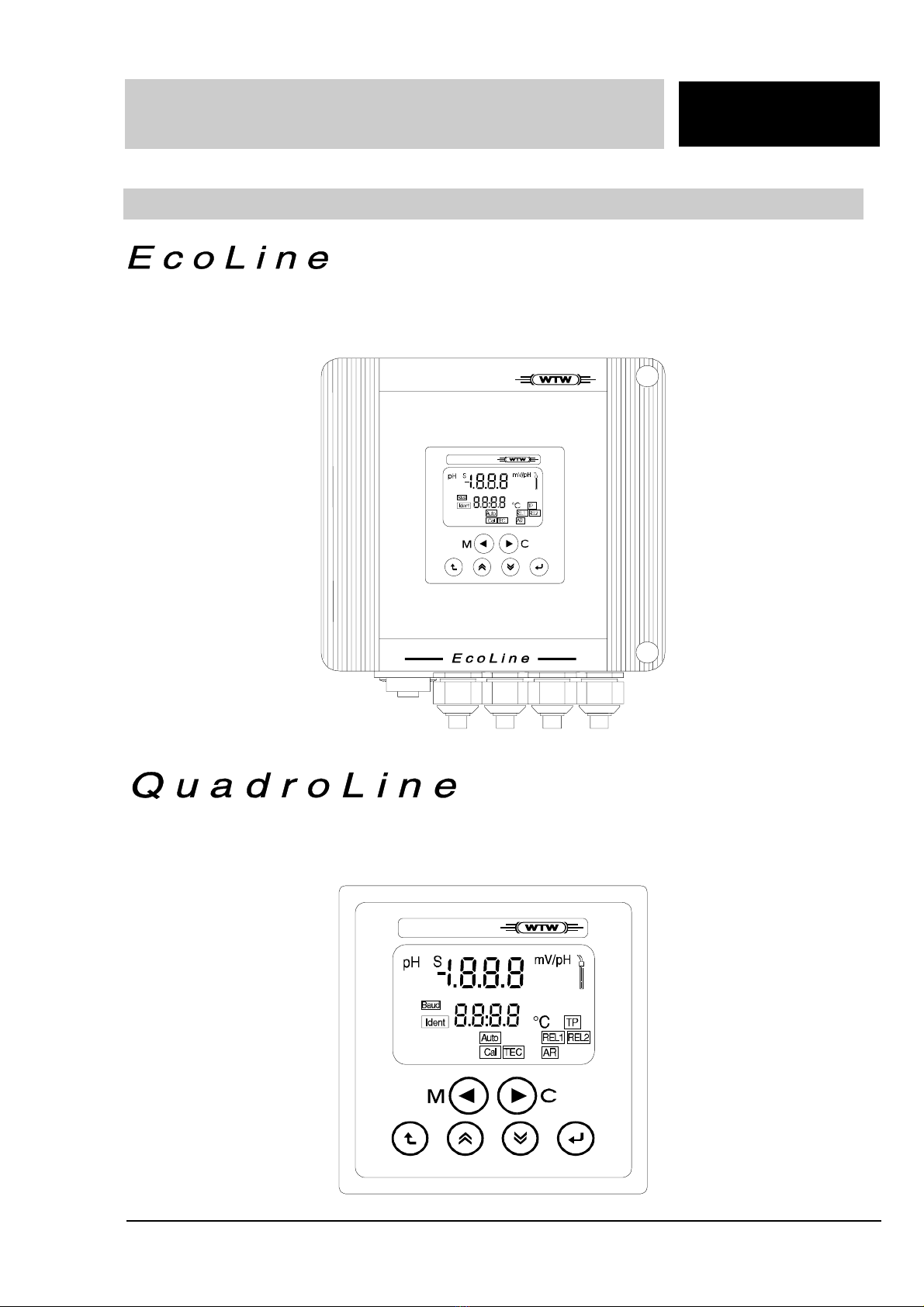

pH 170/

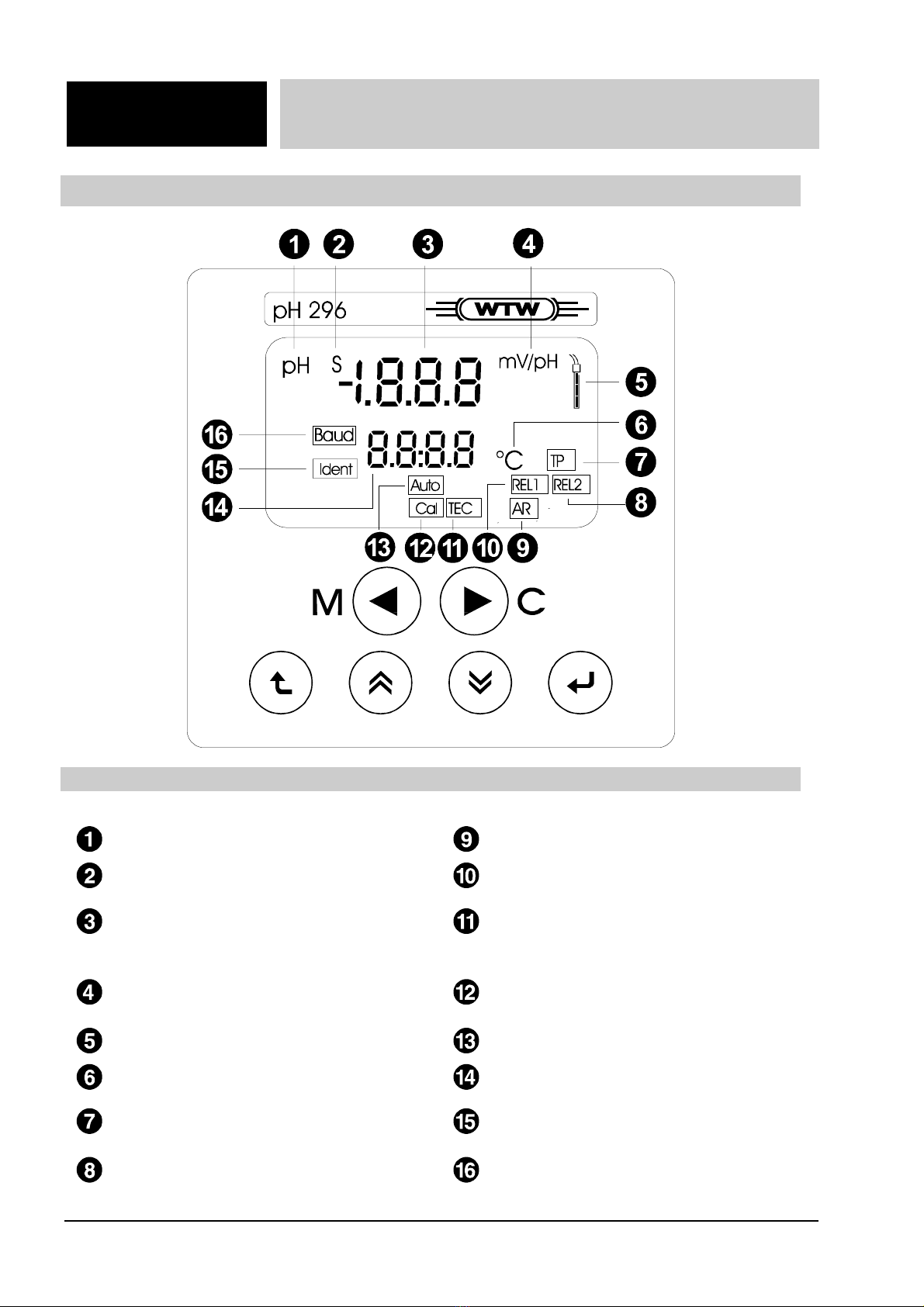

pH 296

95

Configuration......................................................................................................... 120

Factory settings ..................................................................................................... 120

Calling up the configuration level .......................................................................... 121

Overview table of the submenus ...................................................................... 122

Selecting the measuring mode .............................................................................. 122

Selecting the calibrating procedure ....................................................................... 123

Selecting the temperature compensation .............................................................. 124

Selecting the sensor .............................................................................................. 125

Selecting the REC 1 recorder output .................................................................... 126

Selecting the REC 2 recorder output .................................................................... 128

Relay 1/Relay 2 (R option) .................................................................................... 130

Selecting the relay functions.............................................................................. 130

Limit indicator (UL.LL) ................................................................................ 131

Pulse regulator (PI) ........................................................................................... 132

Frequency regulator (PF) ................................................................................. 134

Proportional band, Xp ....................................................................................... 136

Setting procedure for pulse or frequency regulation ......................................... 137

Selecting the switching direction (opener / closer) for FrC, UL.LL .................... 137

Parameterization ................................................................................................. 138

Factory settings ..................................................................................................... 138

Calling up the parameterization level .................................................................... 139

Calling up the parameterization level from the measuring mode ...................... 139

Calling up the parameterization level from the configuration mode .................. 139

Overview table of the submenus ...................................................................... 140

REC 1 and REC 2 recorder outputs (REC 2 only T option) .................................. 141

Relay 1 / Relay 2 (R option) .................................................................................. 142

Limit indicator (UL.LL) ............................................................................................ 142

Setting the parameters for limit indicators ........................................................ 143

Pulse regulator / Frequency regulator.................................................................... 145

Parameters for the pulse regulator / frequency regulator ................................. 146

RS 485 interface (RS option) ................................................................................ 147

Setting up the code ............................................................................................... 147

Redox shift ............................................................................................................ 150

Temperature input in manual temperature compensation ..................................... 151

Temperature compensation .................................................................................. 152

Timer for an external probe cleaning unit (CS) ..................................................... 153

Setting the intervals ............................................................................................... 154