What we have done for you!

● 4-(A) Bed Face Panels

○ Cut to width and length

○ Edge band edges (Top and left for left pane, top and right on right panel and top on center panels)

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● 2-(B) Verticals

○ Cut to width and length

○ Edge band edges (Front edge)

○ Bore the 5 holes on each for mechanism

○ Countersink each hole

○ Bore hole for dowels to locate headboard.

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

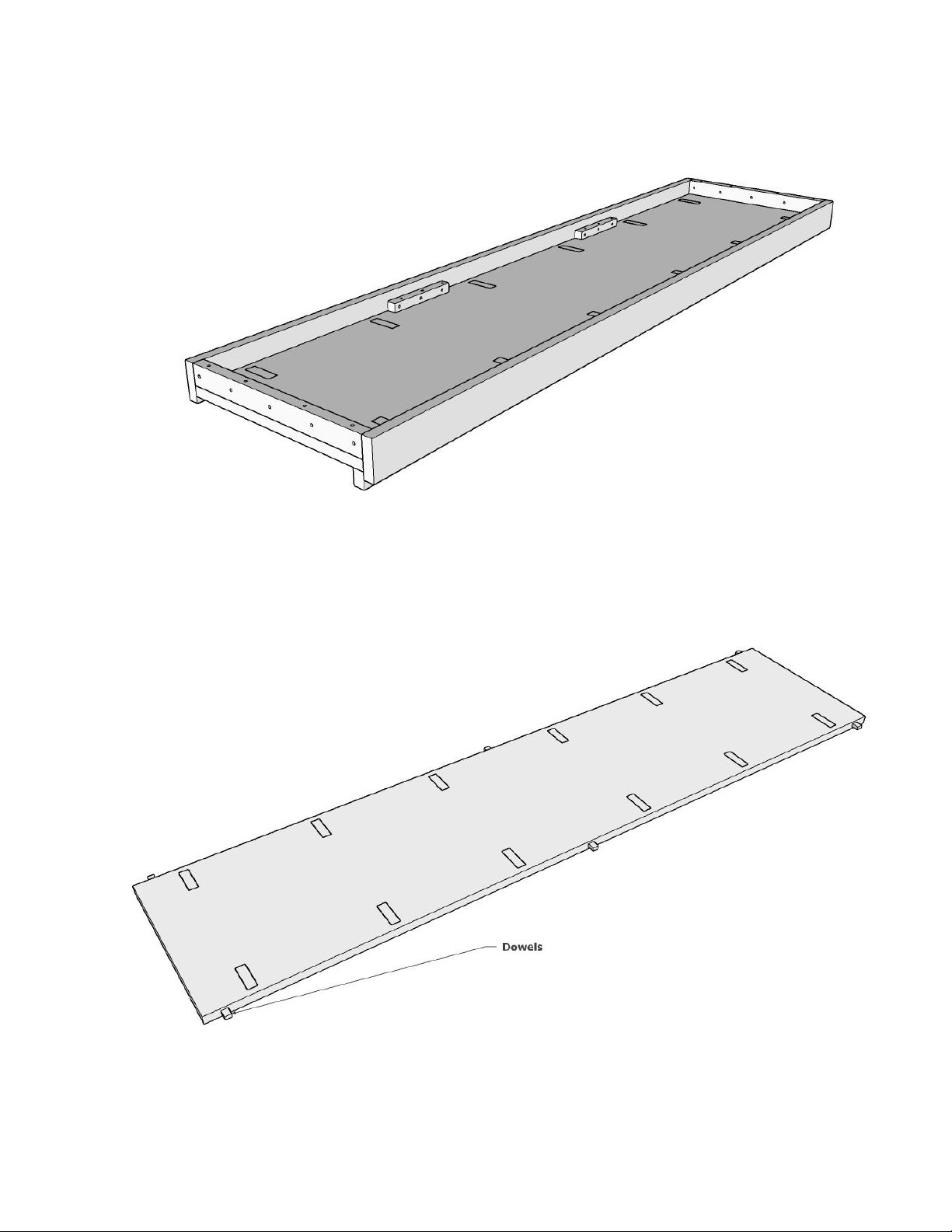

● (C) Headboard

○ Cut to width and length

○ Edge band edges

○ Bore holes for dowels

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● (D) Top Panel

○ Cut to width and length

○ Mortise dowel holes

○ Edge band edge

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● (E) Top Facia

○ Cut to width and length

○ Mortise dowel holes

○ Edge band edges

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● (F) Bottom Rear Base

○ Cut to width and length

○ Edge band edges

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● (G) Bottom Kick

○ Cut to width and length

○ Edge band edges

○ Broke over edges

○ Sanded with to 220 grit (prep for finish)

● (H) Header Cleats

○ Cut to width and length

○ Broke over edges

○ Pre-drilled 9 holes

● (I) Header Stop

○ Cut to width and length

○ Broke over edges

○ Pre-drilled and countersunk 5 holes