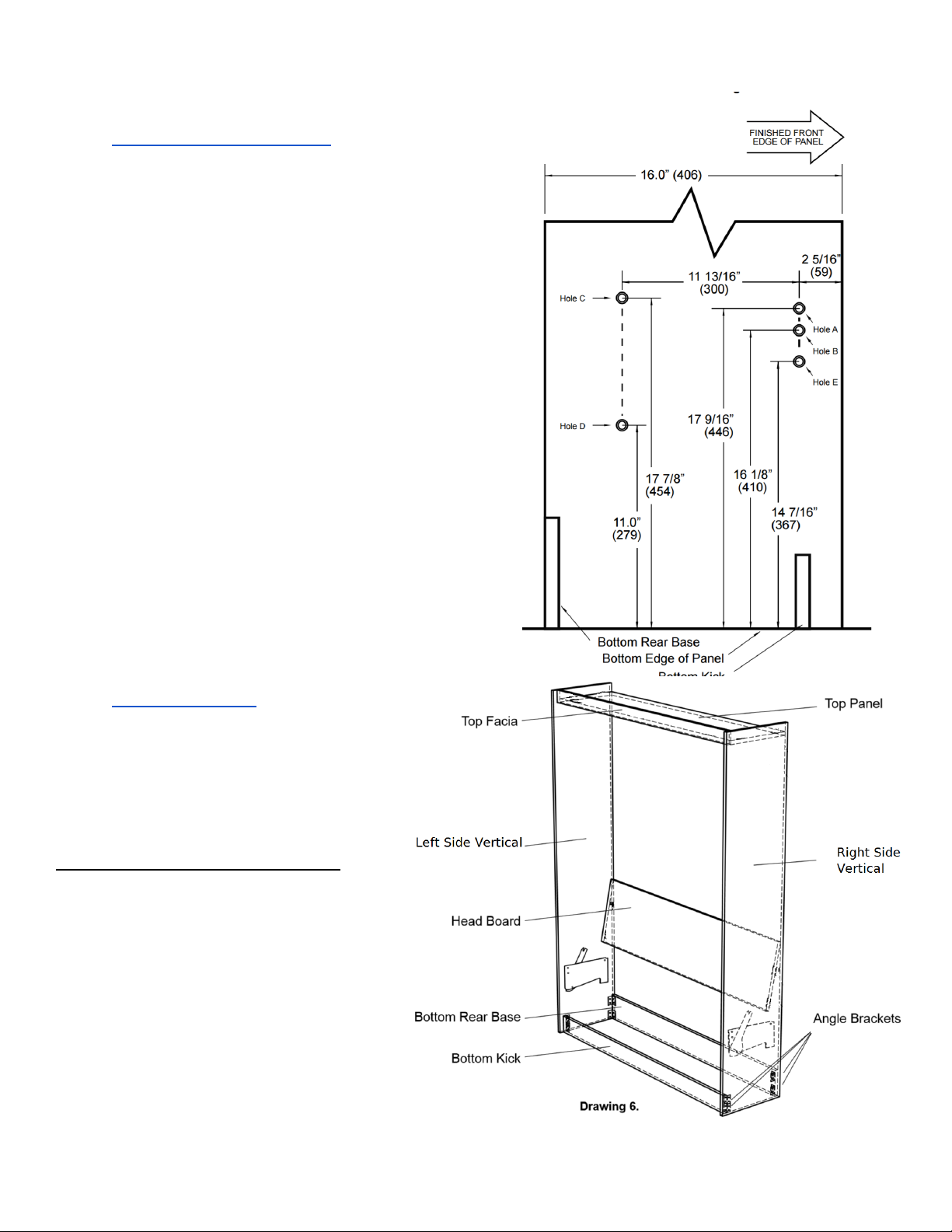

Attach Bed Cabinet Securely to Wall

Video: Attaching to wall

4-1: Find Studs

Prior to placing the cabinet against the wall, locate 3-4 studs on queen size (4-5 on King) or other wall frame

members at the level of the Top Panel (top of bed). Alert: The cabinet must be secured to studs or other wall

structural members or injury and damage could occur. If the wall is not a wood stud wall, use metal stud

screws, toggle bolts or concrete expansion bolts if necessary.

Tip: for help finding studs there are several websites of video available online, just do a google search. One

example: https://www.lowes.com/n/how-to/how-to-find-studs-in-walls

4-2: Attach to wall

Now that the cabinet is square and plumb,

pre-drill a hole in that backboard of the

Top Panel/header at the stud location

using a 3/16” drill bit. Only pre-drill that

back board and not the entire depth into

the stud. Fasten cabinet to wall using 3”

screws. Repeat this for other stud

locations.

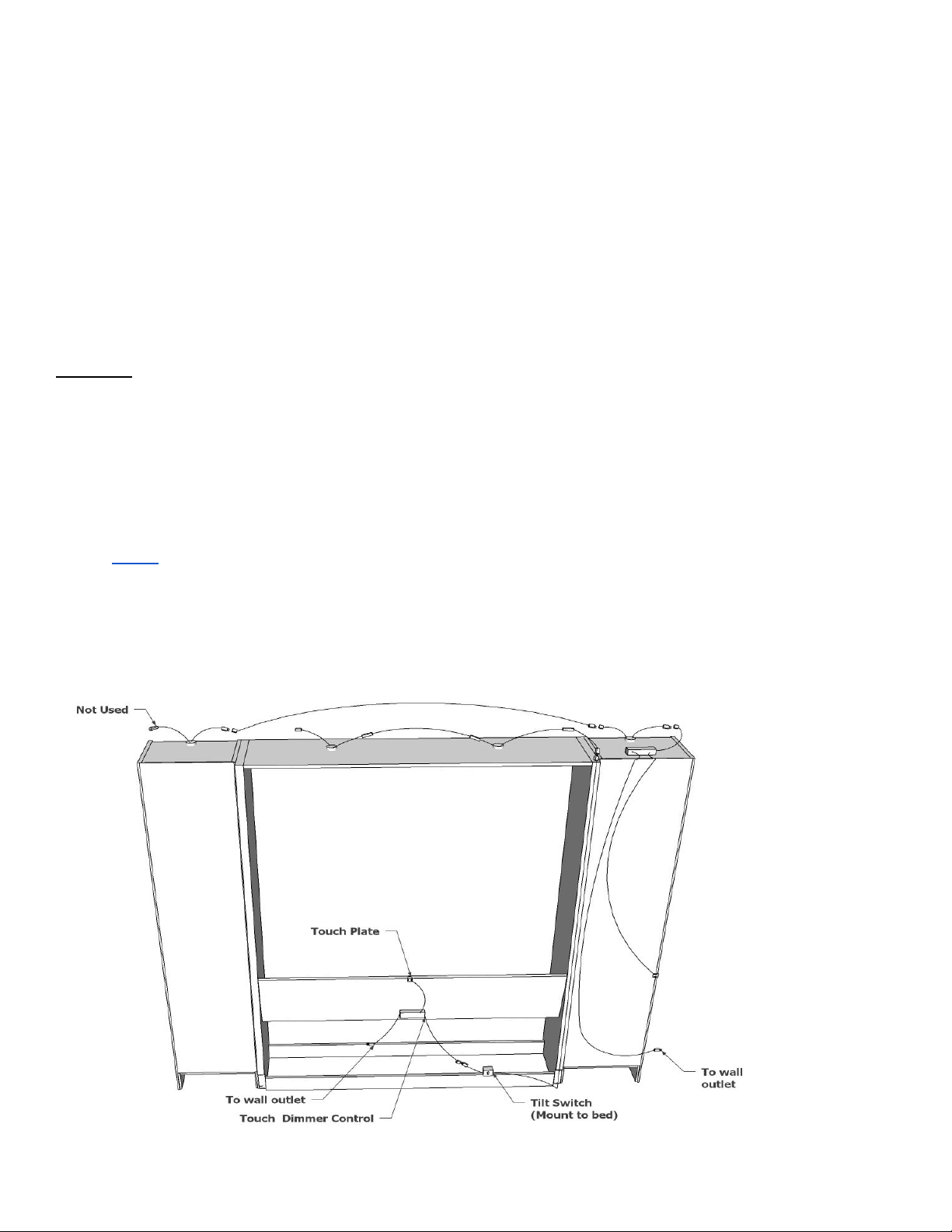

If the wall is CONCRETE, MORTAR OR

BRICK Construction, use masonry screws:

Drill three pilot holes through the rear rail of

the bed header into the wall for a twin or full

and four for a queen size bed. Using a

5/32” concrete drill bit, drill through the pilot

holes into the wall 2” deep. Anchor the bed

by screwing 3/16 x 2 ¼” masonry screw

through the rear rail of the bed header into

the wall.

IMPORTANT:

After the cabinet is securely fastened to the wall, pull on the top of the cabinet. If any movement away

from the wall is detected, repeat the previous steps.