Step 3: Finish all wood components

-Finish both sides of all components.

Tip: By placing pieces like the verticals, headboard and header on legs made from scrap material, you can

finish both sides at the same time and save time flipping.

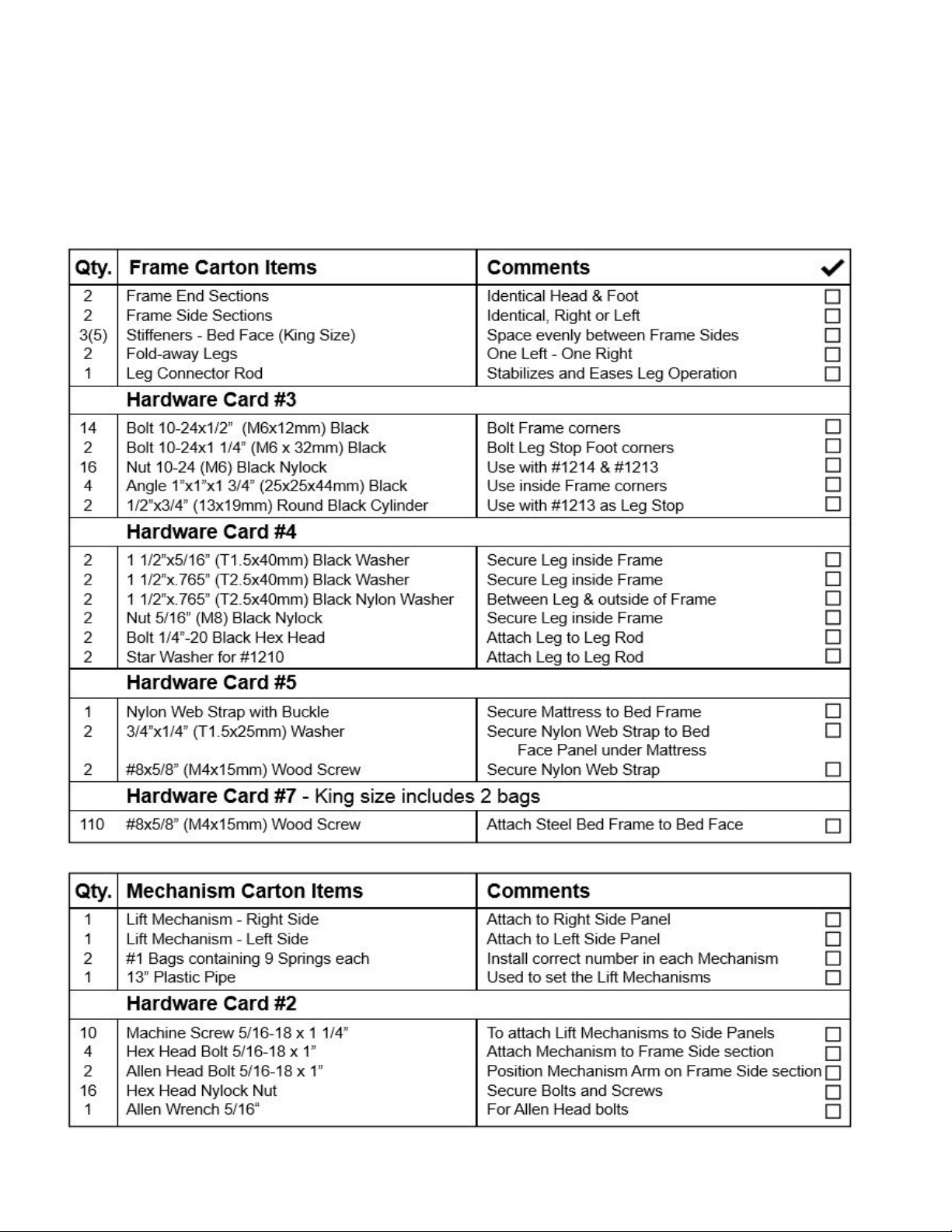

Install the Murphy Bed

Step 4: Install the springs and the Lift Mechanism

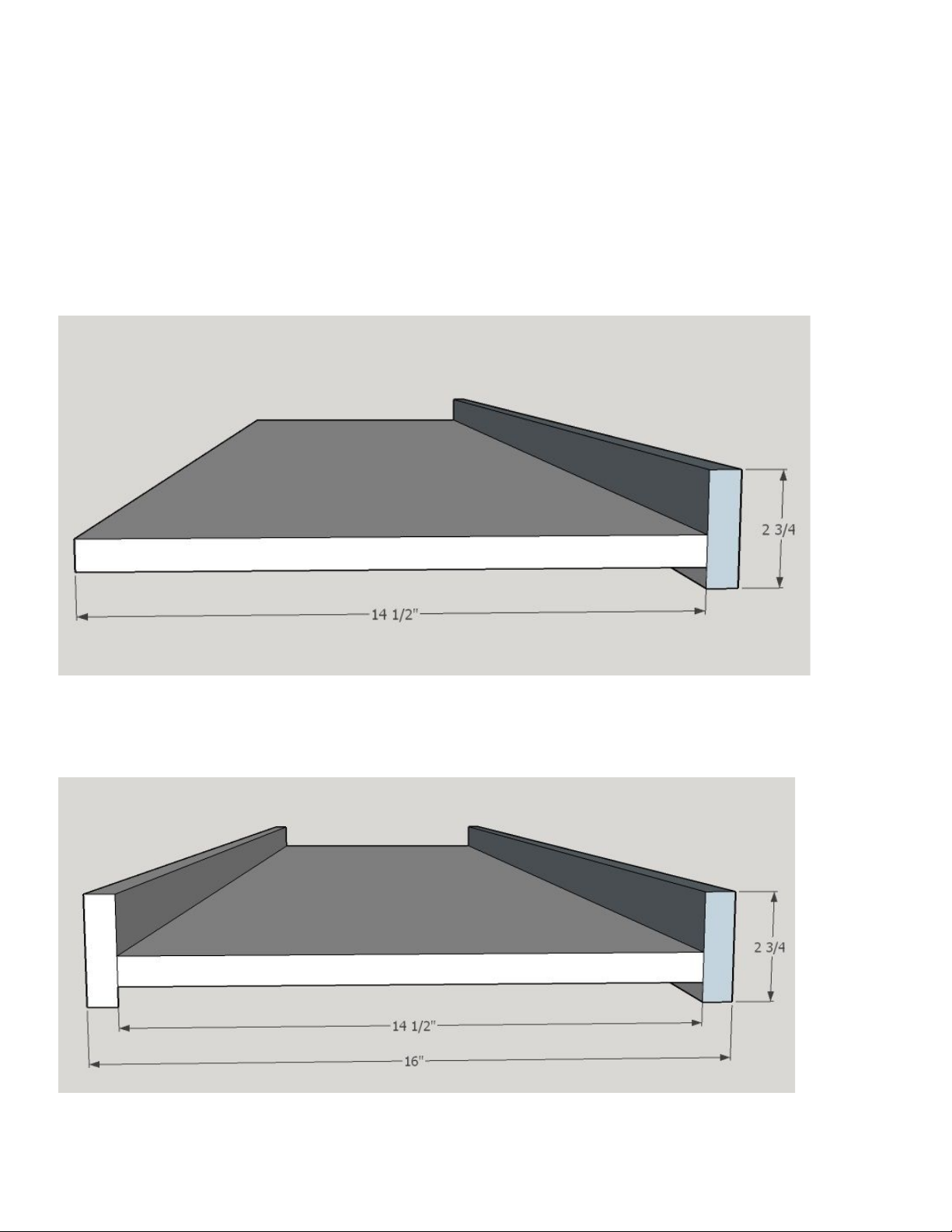

4-1: The left and right mechanism hole pattern will line up with the hole pattern on the Side Panel (B). The

bolts will be fed through the side that has the counter sinks drilled.

4-2 Hole A will not have a standard nut. It is either a threaded hole or it will use a disk like bolt “Arm Lock

Stop”. Get Hole A started.

4-3 Insert the bolt in the other holes and loosely tighten onto the nutes.

4-4 Once all are in place securely tighten using the Allen Wrench provided and a ½” wrench.

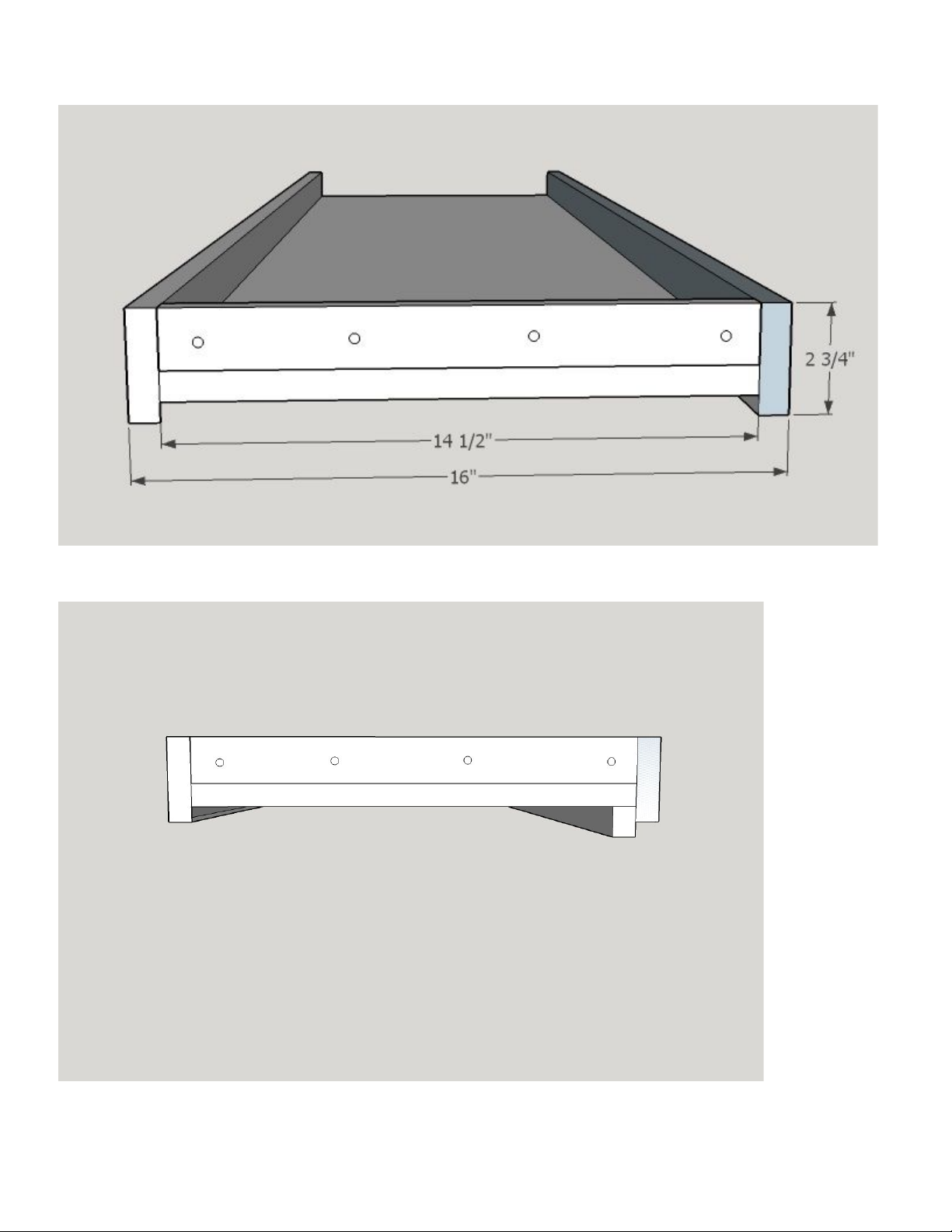

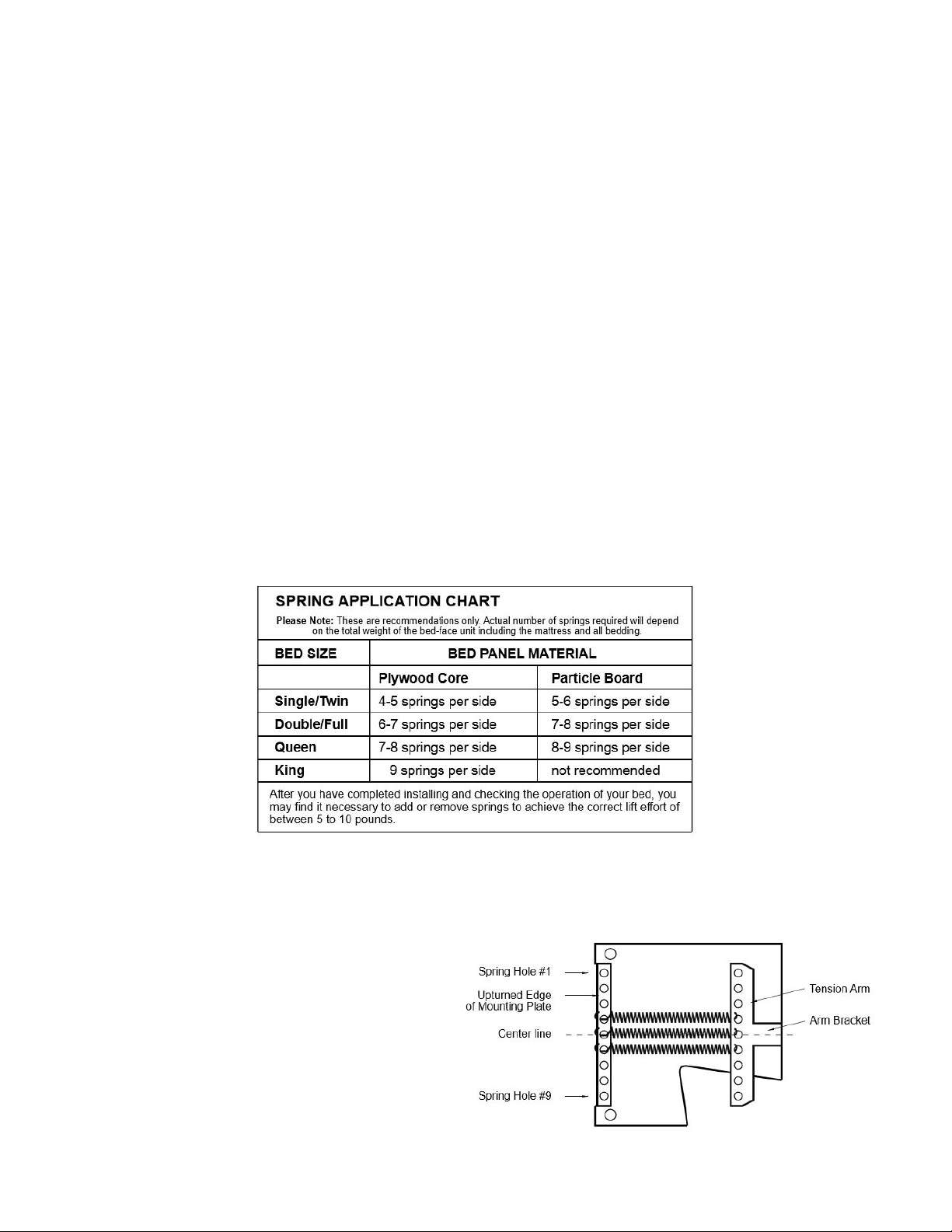

There are nine locations for springs. If the bed requires an even number of springs, do not use the center hole

(#5 from the top). If the bed requires an odd number of springs, start with the center hole (#5 from the top) and

work outward in both directions evenly.

Hook the springs so the open ends are facing

outward. You may have to gently pry up the

tension arm and slide the spring under and snap

them into place in the proper hole, matching the

same numbered hole from the top of the

mechanism back plate. You should have an equal

number of springs on each side of the center

hole.

Use the same number of springs and the same

layout on both the left and right mechanisms.