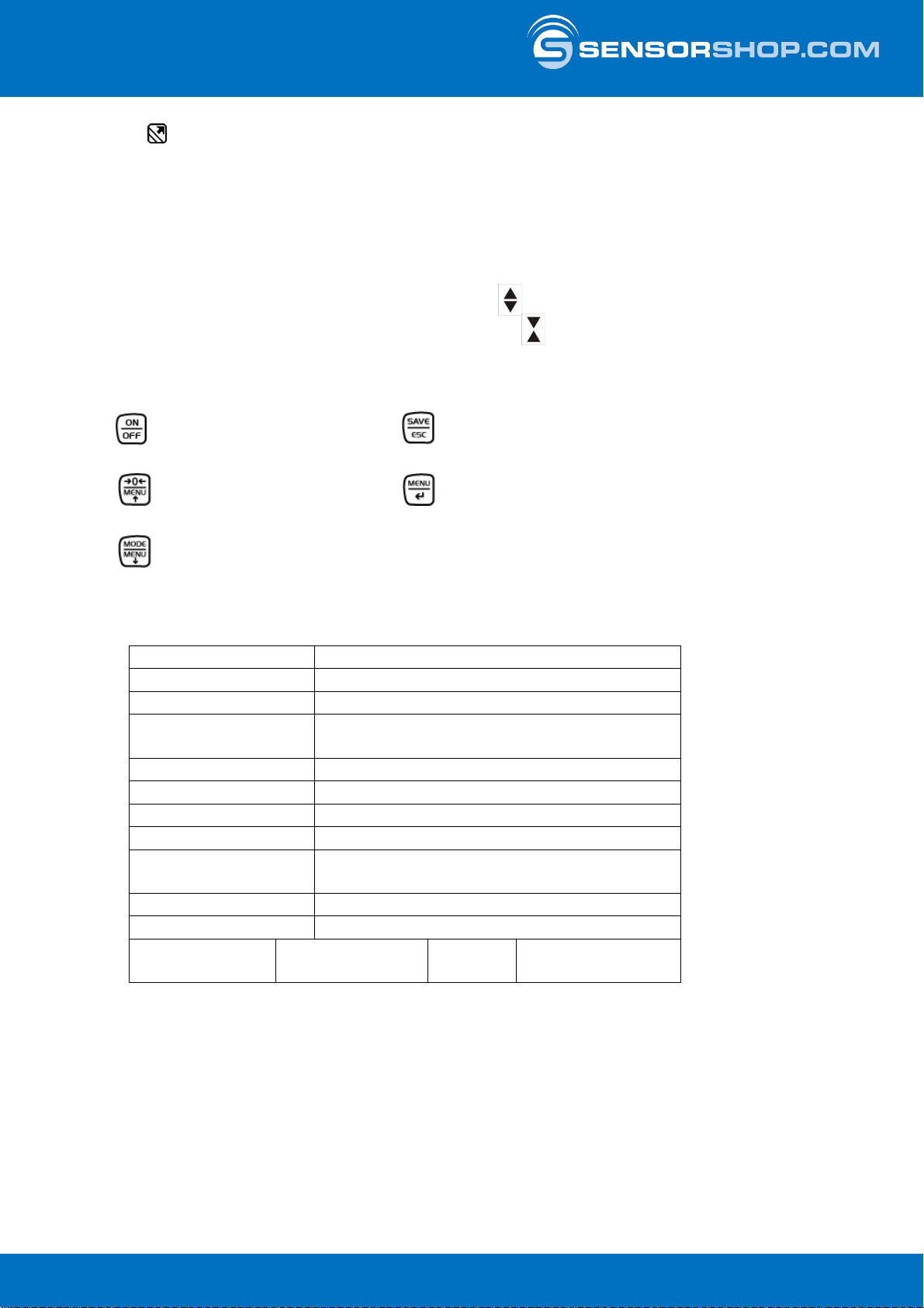

Adjusting program (CAL):

For quick setting of the balance’s accuracy.

External adjusting weight required.

Calibration block:

standard for adjusting or correcting

the measuring device.

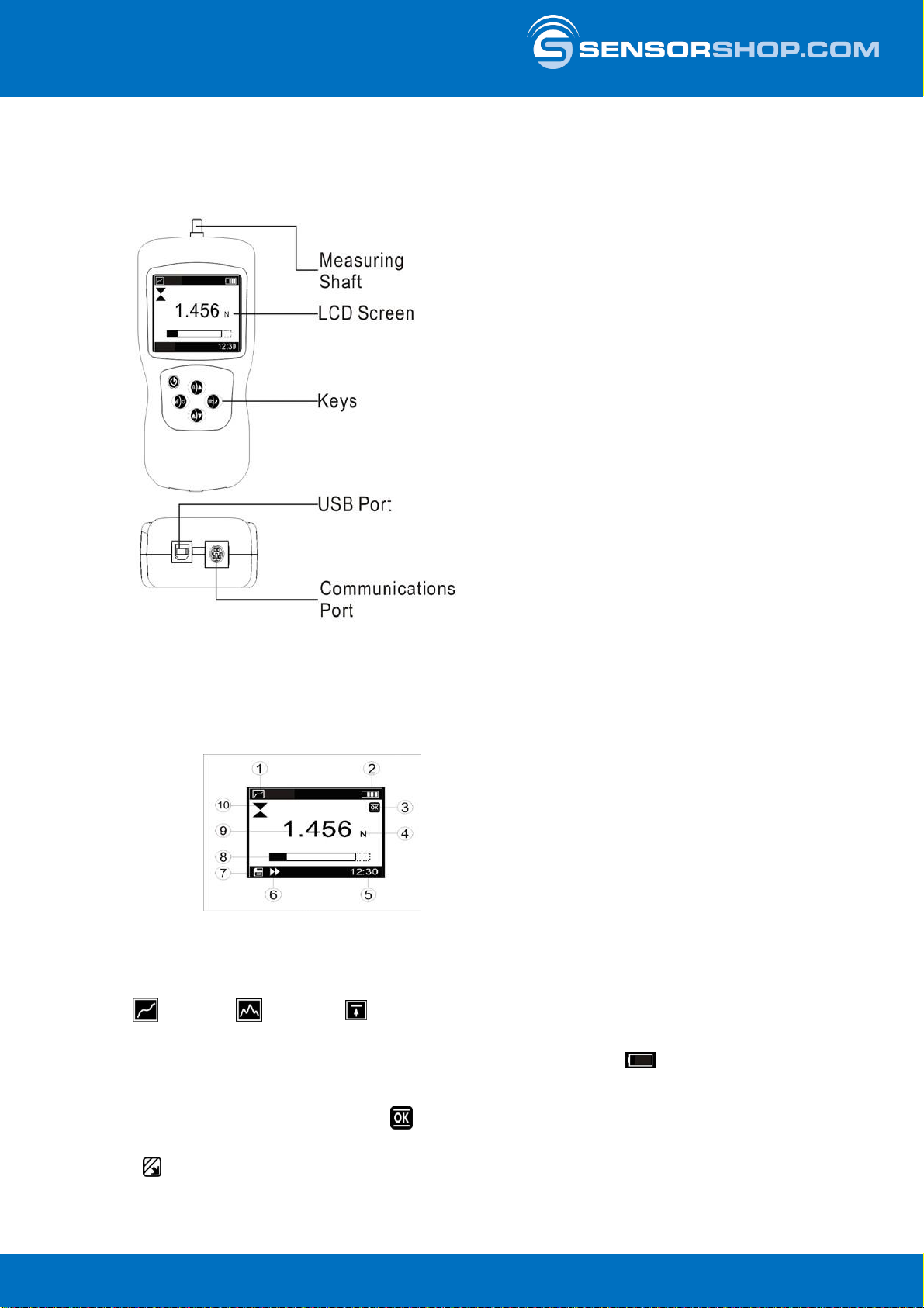

Peakhold function:

capturing a peak value within a

measuringprocess.

Scanmode:

continuous capture and display

of measurements.

PushandPull:

the measuring device can capture tension

and compression forces.

Lengthmeasurement:

captures the geometric dimensions of

a test object or the movement during

a test process.

Focus function:

increases the measuring accuracy of a

device within a defined measuring range.

Internal memory:

to save measurements

in the device memory.

Data interface RS-232:

bidirectional, for connection

of printer and PC.

Data interface USB:

Toconnect the balance to a printer,

PC or other peripheral devices.

Datainterface Infrared:

Totransfer data from the balance to a

printer, PC or other peripheral devices.

Controloutputs

(optocoupler, digital I/O):

to connect relays, signal lamps, valves, etc.

Analogue interface:

to connect a suitable peripheral device for

analogue processing of the measurements.

Statistics:

using the saved values, the device

calculates statistical data, such as

average value,standard deviation etc.

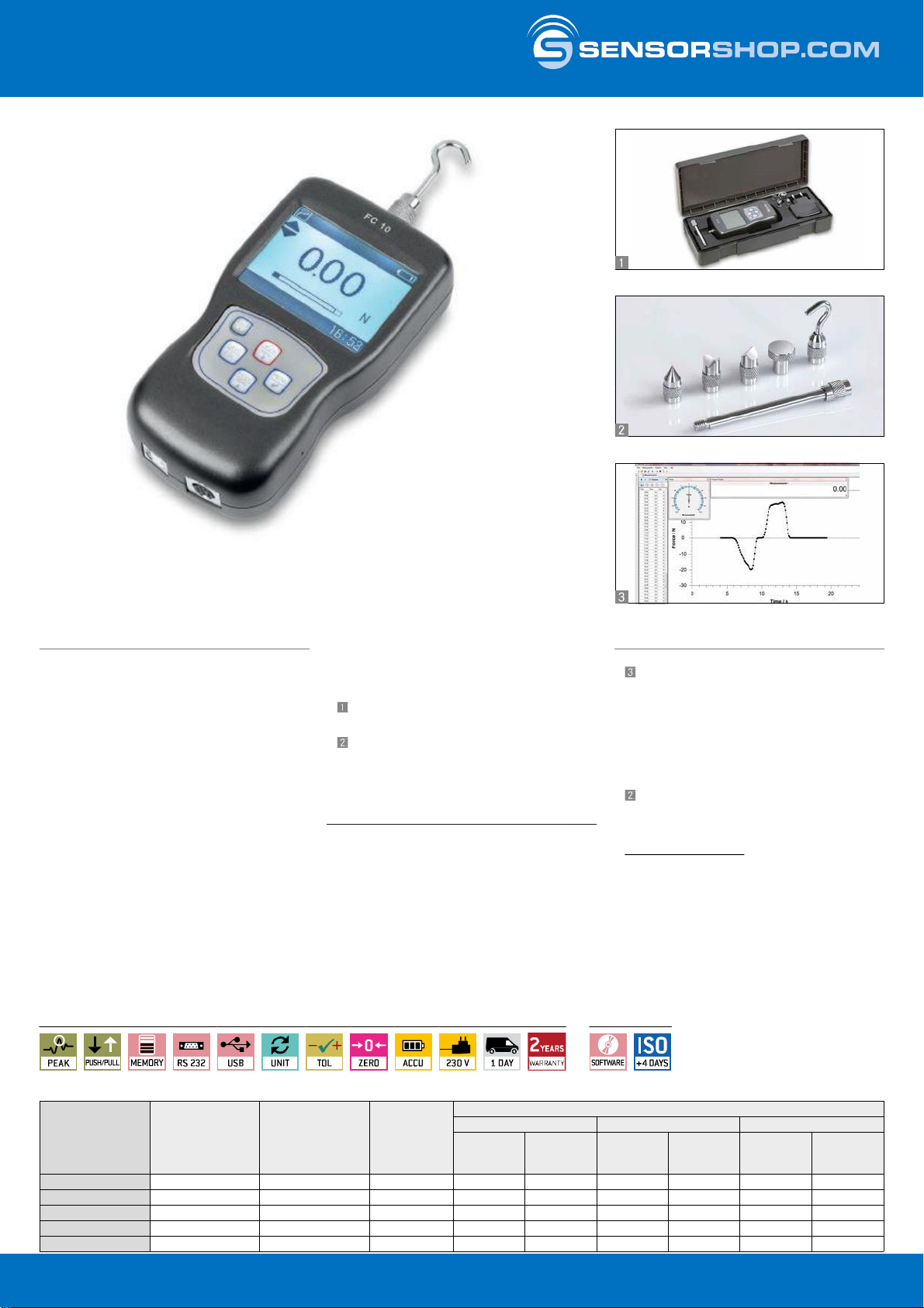

PC Software:

to transfer the measurements from

the device to a PC.

Printer:

a printer can be connected to the

device to print out the measurements.

GLP/ISO recordkeeping:

of measurements with date, time and

serial number. Only with printers.

Measuringunits:

Weighing units can be switched to

e.g. non-metric at the touch of a key.

Please refer to website for more details.

Measuring with tolerance range:

Upper and lower limiting can

be programmed individually,

e.g. for sorting and dosing.

ZERO:

Resets the display to “0”.

Batteryoperation:

Ready for battery operation.

The battery type is specified

for each device.

Rechargeable battery pack:

rechargeable set.

Mainsadapter:

230V/50Hz in standard version for EU.

On request GB, AUS or USA version

available.

Powersupply:

Integrated, 230V/50Hz in EU.

More standards e.g. GB, AUS

or USA onrequest.

Motoriseddrive:

The mechanical movement is carried out

by a motorised drive.

Fast-Move:

the total length of travel can be covered

by a single lever movement.

ISO Calibration:

The time required for ISO calibration

is shown in days in the pictogram.

Packageshipment:

The time required for internal

shipping preparations is shown

in days in the pictogram.

Palletshipment:

The time required for internal

shipping preparations is shown

in days in the pictogram.

Warranty:

The warranty period is shown

in the pictogram.

Pictograms:

X-SENSORS GmbH l Steinbrechstr.9, 71106 –Magstadt, Deutschland l Tel: +49 7159/49697-0 l info@sensorshop.coml www.sensorshop.com

FC X-SENSORS GmbH

Magstadt, Deutschland l Tel: +49 7159/49697-0

info@sensorshop.com l www.sensorshop.com Kompetenz in Messtechnik und Kundenbetreuung