徐州徐工随车起重机有限公司

- 4 -

Content:

A.00 General........................................................................................................................................................6

A.01 Definition of glossary.................................................................................................................................6

A.02 Symbols.......................................................................................................................................................6

A.03 Crane type & meaning...............................................................................................................................6

A.04 Crane nameplate........................................................................................................................................6

A.05 Warning.......................................................................................................................................................7

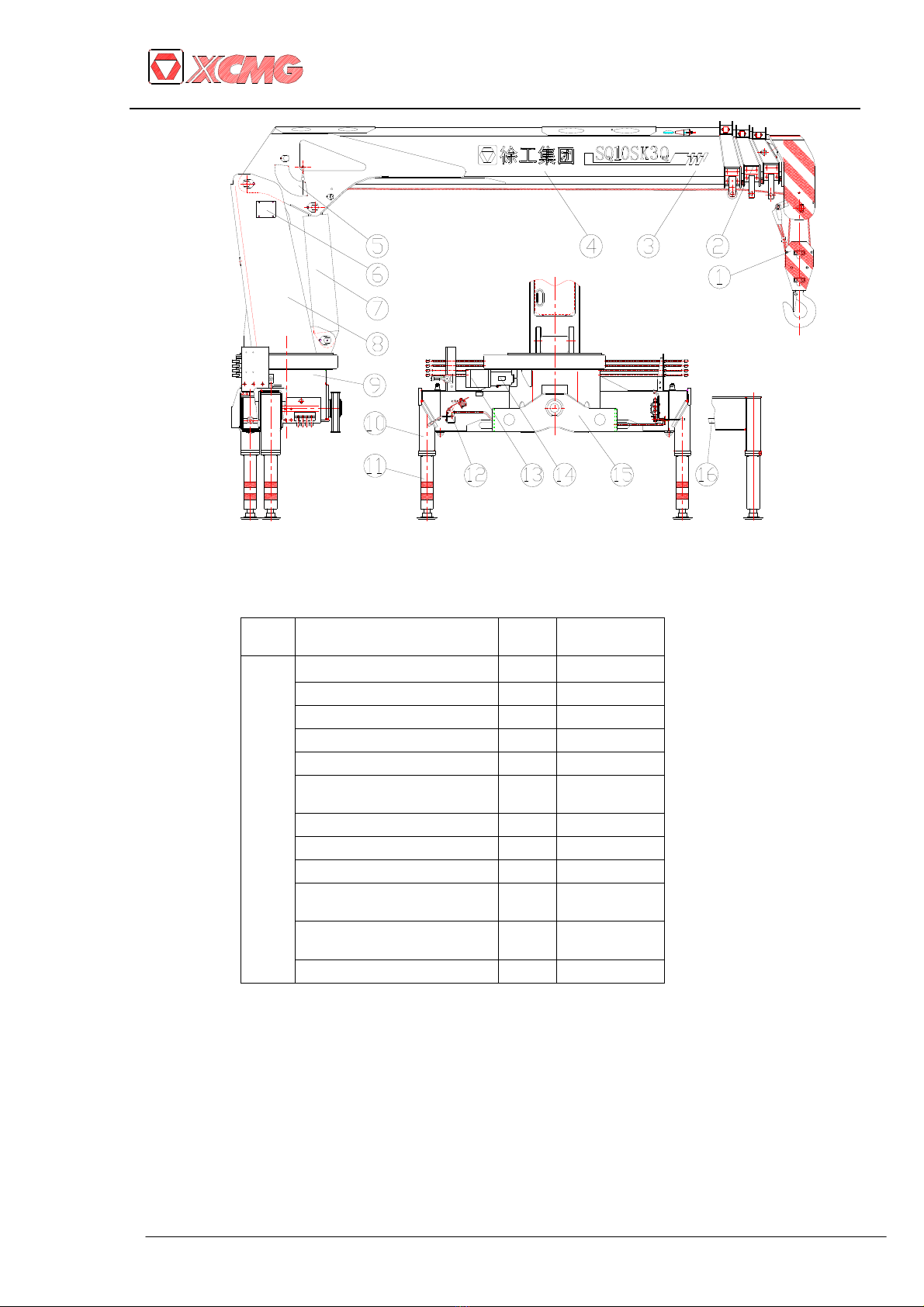

A.06 Main parts name of the crane...................................................................................................................7

B.00 Description of performance data ..............................................................................................................8

B.01 Working Data..............................................................................................................................................8

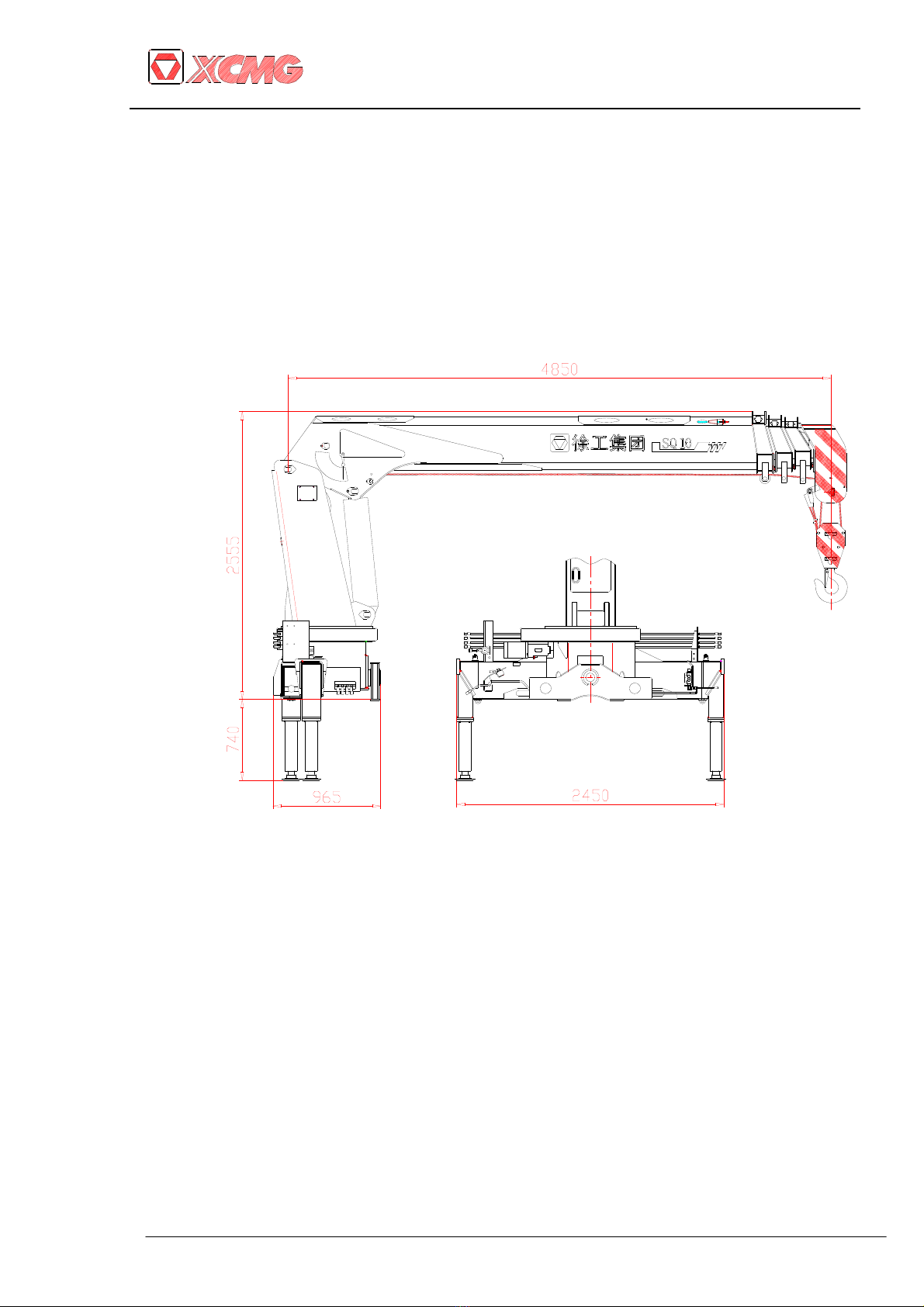

B.02 Slewing base and active leg........................................................................................................................9

B.03 Hydraulic system........................................................................................................................................9

B.04 Movement speed.........................................................................................................................................9

B.05 Overall dimensions...................................................................................................................................10

B.06 Boom working range................................................................................................................................10

B.07 Crane character graph.............................................................................................................................11

B.08 Theory chart of hydraulic system...........................................................................................................12

B.09 Selecting of parts line of rope..................................................................................................................12

C.00 Safety rules & device................................................................................................................................12

C.01 Working condition....................................................................................................................................12

C.02 Environment condition............................................................................................................................12

C.03 Requirement for rope use........................................................................................................................13

C.04 General description of safety rules.........................................................................................................13

C.05 Safety devices............................................................................................................................................17

C.05.1 Lock device on fixed legs ......................................................................................................................17

C.05.2 Valves on hydraulic cylinders...............................................................................................................17

C.05.3 Anti-rotation device...............................................................................................................................17

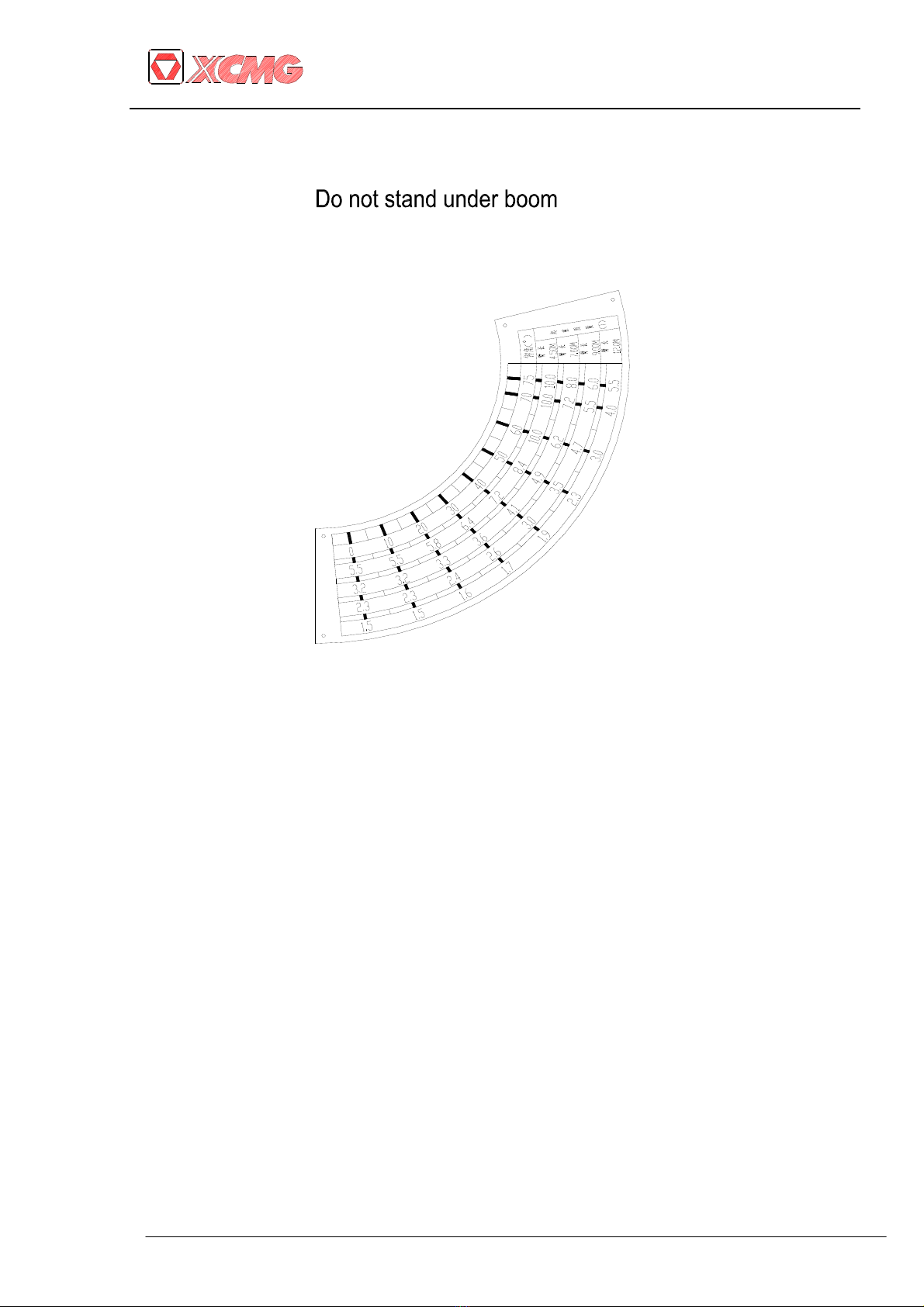

C.06 Forecast risk and unforecast risk area...................................................................................................18

D.00 Operator....................................................................................................................................................18

D.01 Essential requirements.............................................................................................................................18

D.02 Duties and Responsibilities......................................................................................................................19

D.03 Control stations........................................................................................................................................19

E.00 Control devices .........................................................................................................................................19

E.01 Oil level indicator.....................................................................................................................................19

E.02 Crane operation controls.........................................................................................................................19

E.02.1 Boom, column and lift machine control lever.....................................................................................20

E.02.2 Stabilizer control lever..........................................................................................................................21

F.00 Operating instruction...............................................................................................................................22

F.01 Notice before operating ............................................................................................................................22

F.02 Start-up operations...................................................................................................................................23

F.03 Stabilizing the crane..................................................................................................................................23

F.04 Opening the crane.....................................................................................................................................23

F.05 Operating telescopic boom.......................................................................................................................25

F.06 Closing the crane.......................................................................................................................................25