- 3 -

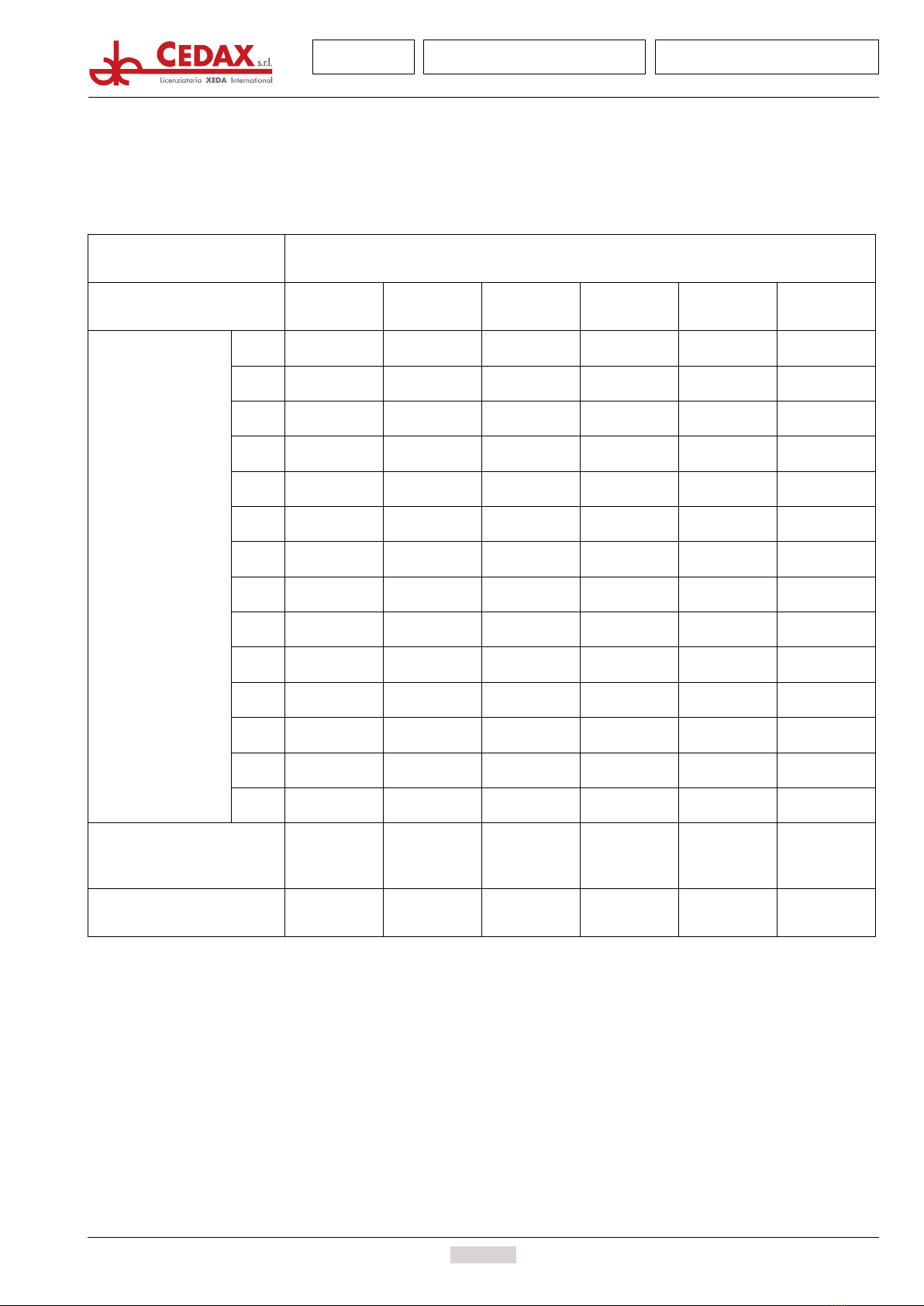

TABLE OF CONTENTSELECTROFOGEWV

3.4.a Risks for exposed persons ...............................................................................................28

3.5 RULES FOR ADJUSTMENTS AND MAINTENANCE ......................................................29

3.6 SAFETY STANDARDS FOR ELECTRICAL EQUIPMENT...............................................30

3.7 SAFETY STANDARDS FOR TESTING AND TRAINING .................................................31

3.8 SAFETY STANDARDS ON ENVIRONMENTAL IMPACT.................................................31

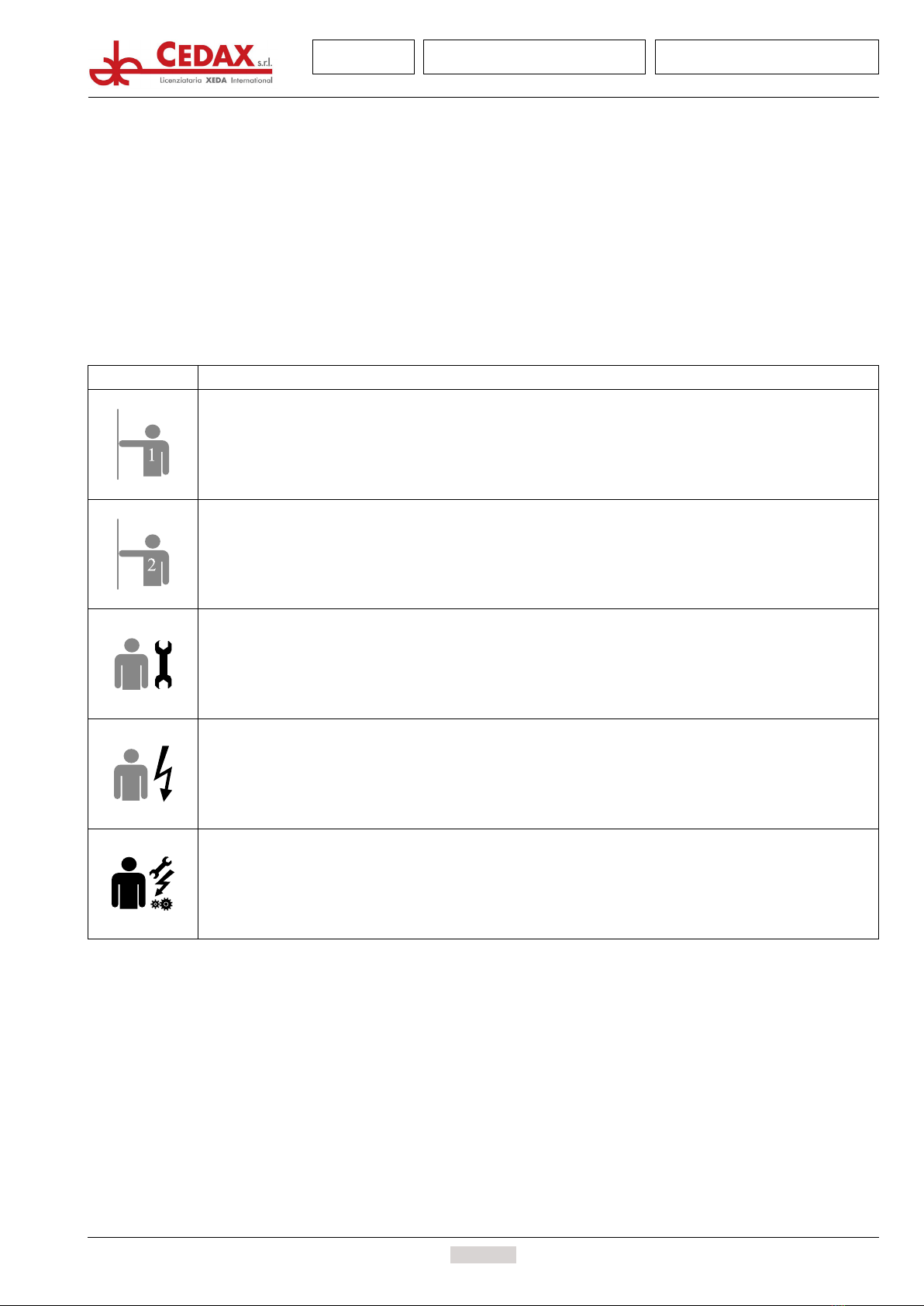

3.9 DESCRIPTION OF SAFETY SIGNS .................................................................................32

3.10 DESCRIPTION OF SAFETY DEVICES.............................................................................33

3.11 RESIDUAL RISKS.............................................................................................................33

4. TRANSPORTATION, HANDLING, STORAGE...............................................35

4.1 GENERAL WARNINGS.....................................................................................................35

4.2 TRANSPORTATION METHODS .......................................................................................35

4.3 STORAGE AND WAREHOUSING METHODS .................................................................36

4.4 PACKAGED MACHINE TRANSPORTATION AND HANDLING ......................................37

4.4.a Unpacking ........................................................................................................................37

5. INSTALLATION...............................................................................................39

5.1 PERMITTED ENVIRONMENTAL CONDITIONS...............................................................39

5.1.a Temperature .....................................................................................................................39

5.1.b Lighting.............................................................................................................................39

5.1.c Atmospherewithriskofexplosionand/orre...................................................................39

5.2 SPACE REQUIRED FOR USE AND MAINTENANCE......................................................39

5.3 MACHINE ASSEMBLY......................................................................................................40

5.4 PLACEMENT OF THE MACHINE.....................................................................................41

5.5 CONNECTION TO ENERGY SOURCES AND RELEVANT CONTROLS ........................43

5.5.a Electrical connection ........................................................................................................43

6. USING THE MACHINE ...................................................................................45

6.1 GENERAL WARNINGS.....................................................................................................45

6.1.a Operator workstation ........................................................................................................45

6.2 PRELIMINARY OPERATIONS ..........................................................................................45

6.2.a Fire prevention .................................................................................................................46

6.2.b Safety device....................................................................................................................47

6.3 USING THE MACHINE......................................................................................................48

6.3.a Commissioning instructions..............................................................................................48

6.3.b Stopping the machine.......................................................................................................48

6.3.c Using XEDA Aerosol Products .........................................................................................49

6.3.d Emergency conditions ......................................................................................................49

7. MAINTENANCE AND REPAIR .......................................................................51

7.1 GENERAL WARNINGS.....................................................................................................51