TEAM TIP: This is the easiest point at which to center your servo. The quickest way

to do this is to plug the servo into another car, and power it on briefly.

Alternatively, if you have the electronics you’ll be installing in your X – 6 Squared

handy, simply hook the battery, speed controller, receiver, and servo. Turn it on

long enough for the servo to power up and center itself (and who can resist

moving the transmitter just a little?). You’ll do the fine adjustments once

everything is installed in the car; this quick centering process gets the servo in

the ballpark.

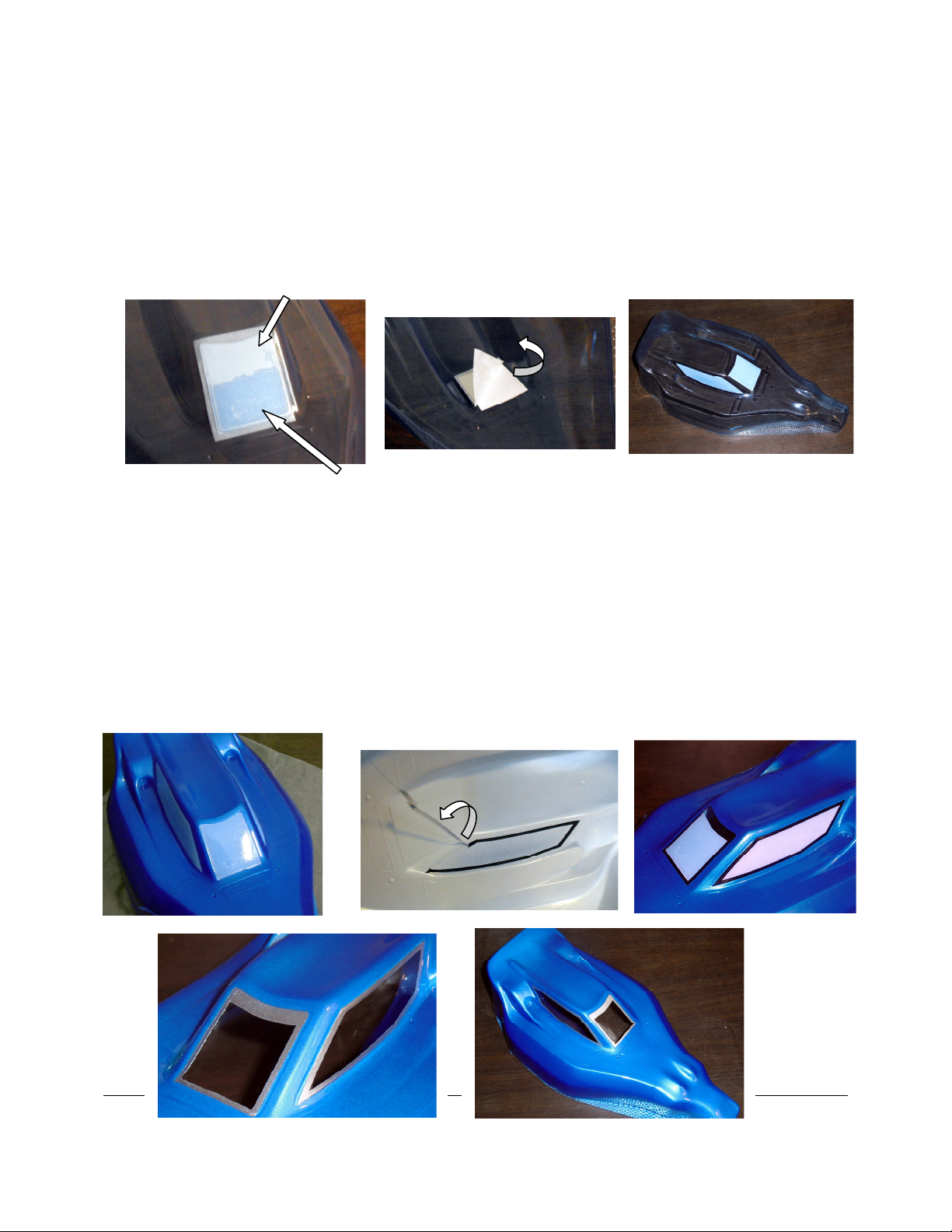

I3) Remove the servo horn tree (ASC

9180); notice each horn has a letter on

it. Choose the horn appropriate for

your servo:

A – Airtronics/Sanwa

H – Hitec

J – JR and KO

F – Futaba

The only difference in the horns is the number of splines; if the horn seems

unusually hard to install on your servo try a different horn. With the servo

centered, put the horn on pointing straight up. (left) Carefully remove the horn

and move it one spline to the right, or clockwise. (center) Secure the horn with

the bolt included with your servo. (right)

I4) Find the 3/16” ball stud (6170) in the hardware bag for

installation in the servo horn. If you’re installing the

servo in the forward position, you’ll want to put the ball

stud in from the back, so it faces the servo (shown in

these pictures). If the servo will be in the rear position,

install the ball stud from the front of the servo horn.