K021 Instructions v1.0 First Things Page 4

SOME IMPORTANT INFORMATION

This is the first time we have made the entire Kit – always before we have made

Conversion Kits. We know we are not perfect. If you experience the slightest

difficulty assembling your X – 6 Squared – if you have trouble with an instruction

or if something does not fit properly – please contact us immediately. Even if you

figure out what needs to be done or modify the part to fit, we will make changes

to help the next person.

Here at X Factory we do not have customers. You have become a member of a

world-wide Family of R/C racing enthusiasts who love working on their cars,

trying new things, helping each other at the track, and winning races. The Family

constantly gives us ideas for new products or improvements to existing products.

We welcome and encourage this input. Thanks in advance for your help!

Phone +01 1-419-877-1787

(U.S.A.)

Snail mail

X Factory R/C Racing Products

P.O. Box 2361

Whitehouse, Ohio 43571 U.S.A.

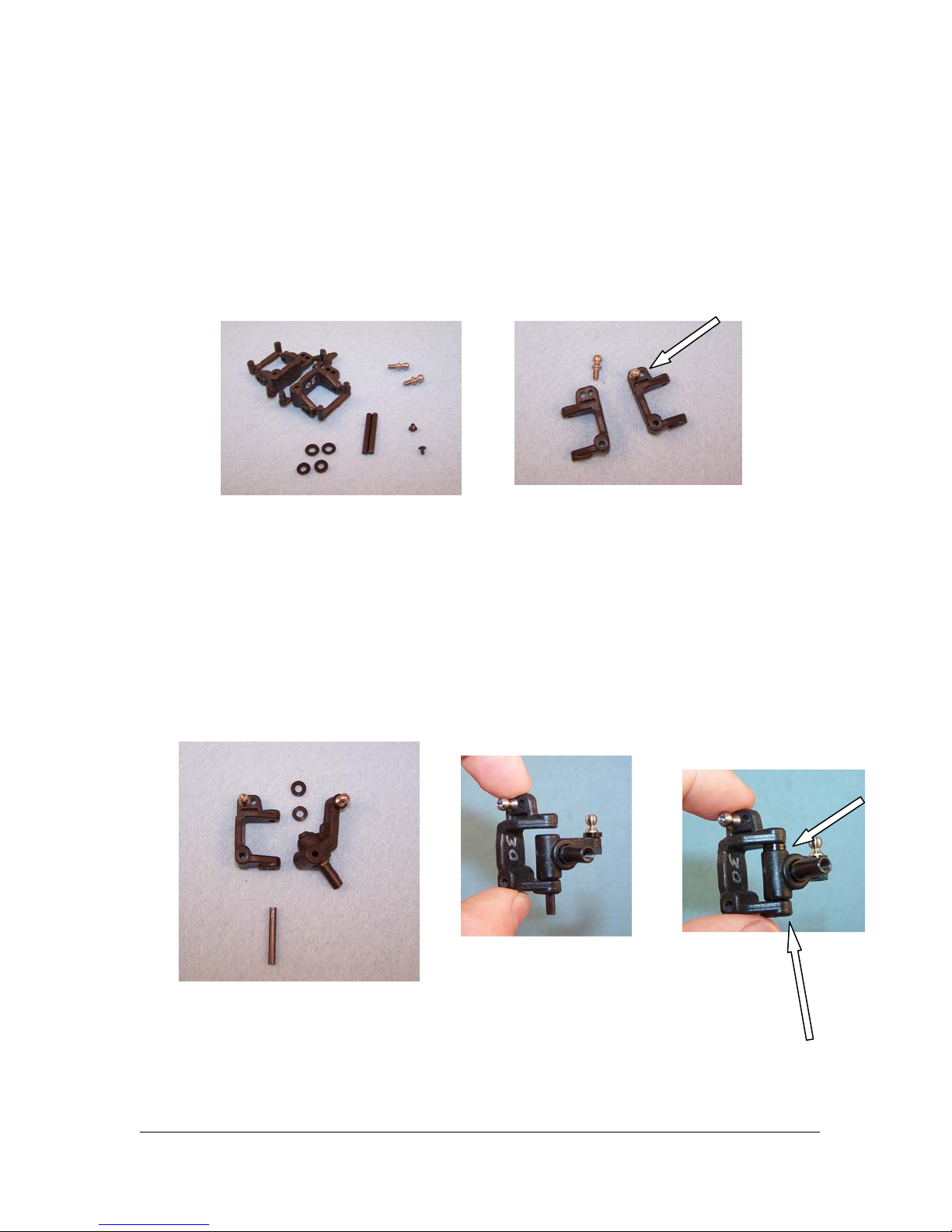

These instructions are available on our

Web site, www.xfactoryrc.com in the

Tech section. Many of the color photos

on the web are better than the black

and white versions here. You are

welcome to download all or any part

of the website manual.

THANK YOU FOR YOUR

CONFIDENCE IN

THE NEW MATH!

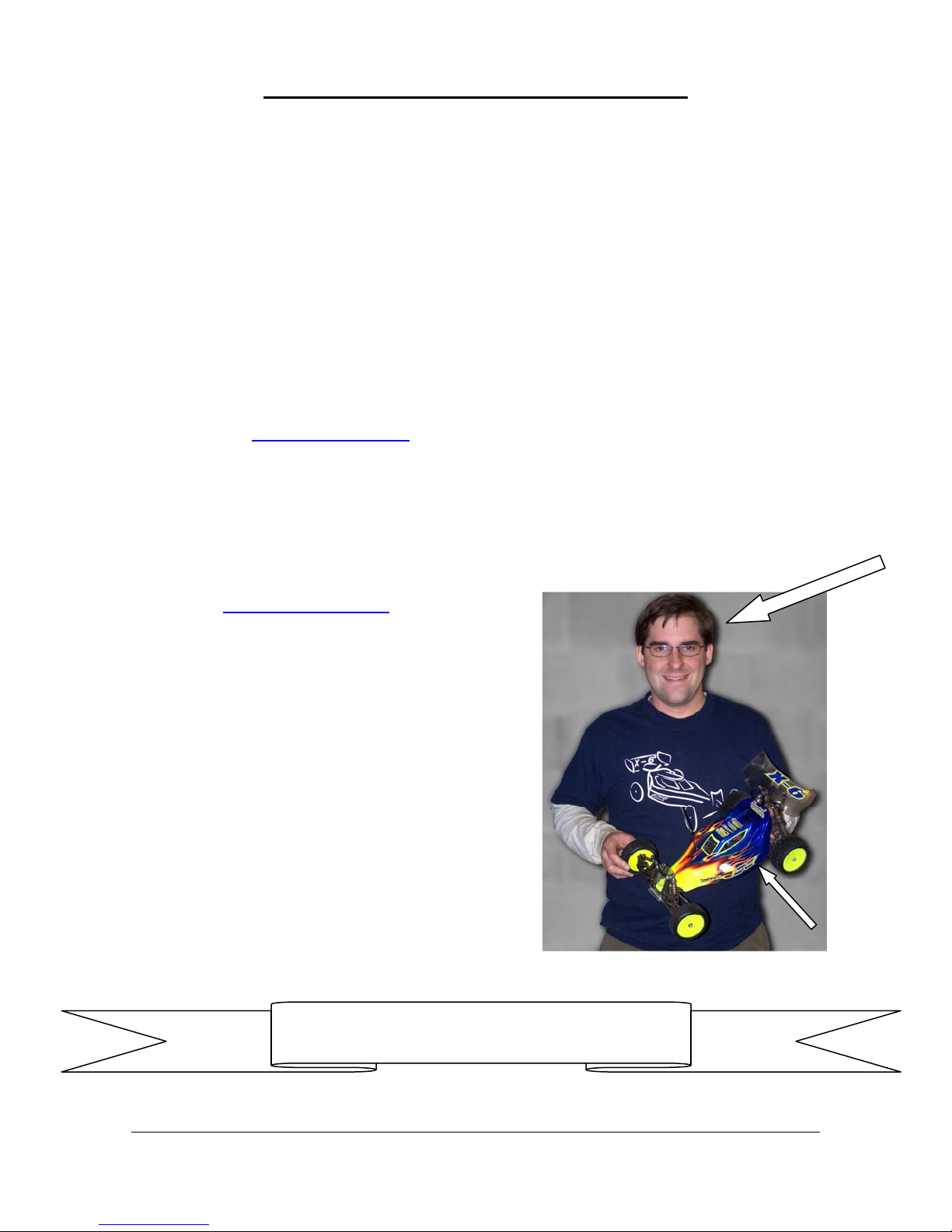

Chief Engineer and designer

Of the X – 6 Squared

Paul Sinclair (large arrow)

His X – 6 Squared (small arrow)