3

OPERATION / MAINTENANCE

The correct position during cutting and must be properly set for each rebar before making a cut.

Screw in stopper to provide sufcient clearance for rebar. Insert rebar fully into U-shaped support.

Make sure that rebar is resting on the base of the stopper. Keeping rebar at right angels (90 °) to front

cutter block, screw out the stopper until it is just touching the rebar. Once set, the stooper needs no

further adjustment while cutting rebar of the same diameter, but must be re-set for a different size rebar.

Caution: Failure to correctly set the stopper will result in excessive wear of the cutter block and may cause

the cut end to y out.

CUTTING

Insert rebar between stopper and front cutter block, making sure that it is properly seated in U-shaped support..

Pull the trigger switch and keep depressed while piston advances and rebar is cut. If the switch is released at

an intermediate point, the piston will stop. When the cut is completed, release the switch. The Piston retracts

automatically. Note that the switch can’t be re-activated until piston has fully retracted.

Be especially careful when cutting off short lengths (11.5 inches or less) the cut end tends to y out at shorter

lengths.

Caution: Flying ends are a hazard to all personnel in the vicinity.

Do not cover air vents. If events are covered, the motor will overheat and may burn out.

If hydraulic oil exceeds (158 F) in temperature the power will drop.

Insert rebar between stopper and front cutter block, making sure that it is properly seated in U-shaped support..

Pull the trigger switch and keep depressed while piston advances and rebar is cut. If the switch is released at

an intermediate point, the piston will stop. When the cut is completed, release the switch. The Piston retracts

automatically. Note that the switch can’t be re-activated until piston has fully retracted. Allow until to cool before

resuming operation. (Be particularly careful in summer, when the aluminum pump case heats up quicker.)

If a drop in power is observed and motor is unusually hot, check carbon brush.

If piston should ever fail to retract completely, push rear cutter block backwards to manually retract piton.

Caution: Use a rebar or at metal bar for this purpose. Never push cutter block with any part of the hand,

even if gloved. Once piston has been retracted , pull trigger-switch long enough to partially advance piston.

Unplug unit. And check piston and housing for accumulated dust iron lings that may be jamming the piston.

After cleaning, piston still does not automatically retract when fully extended, the piston itself may be damaged.

Return the unit to an authorized agent for repair.

MAINTENANCE

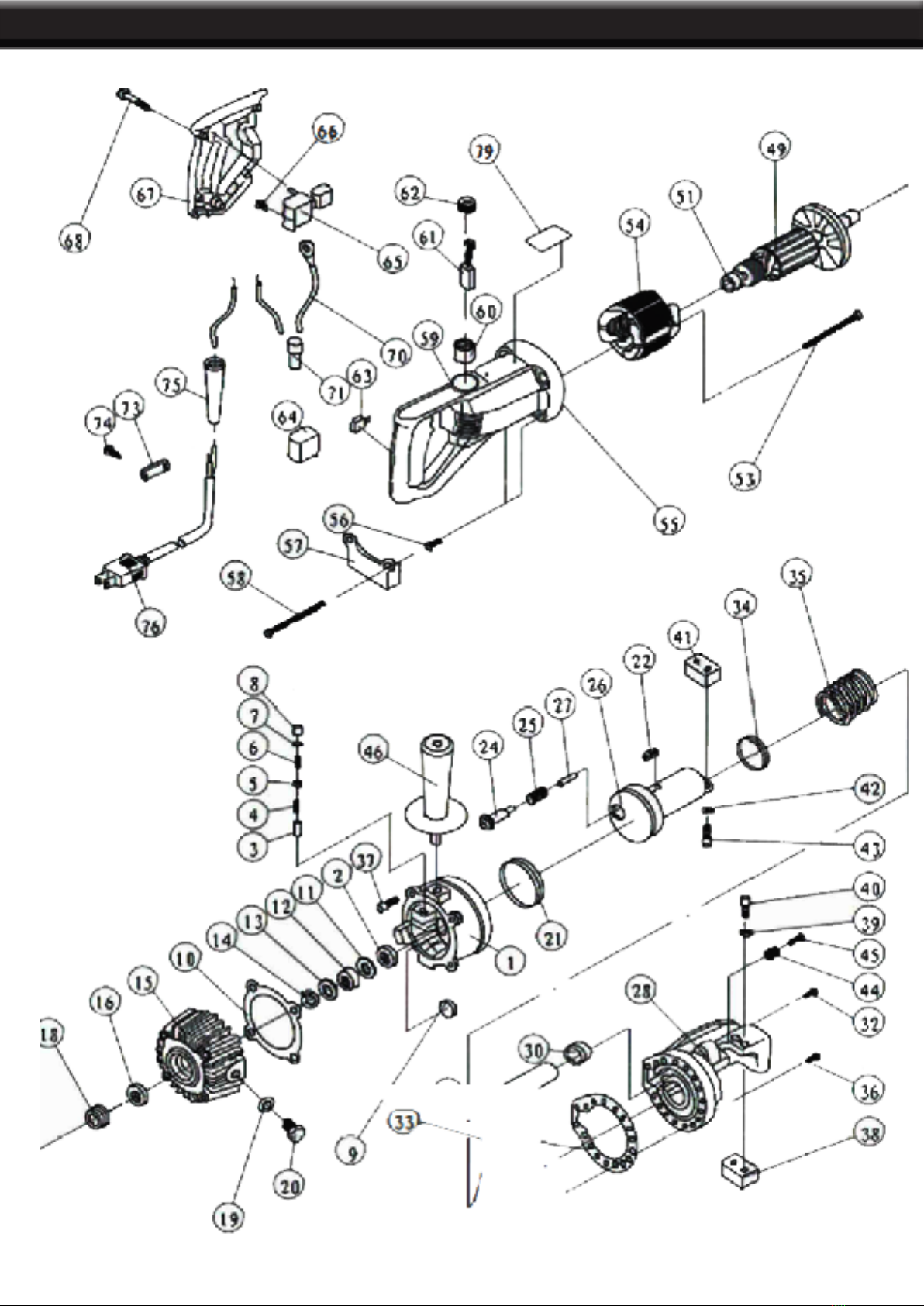

Cutter blocks: Before using, always check that the two bolts on each cutter block are properly

tightened. Using a loose block will result in damage to block and housing. Also check condition of

cutter blocks. If either cutting edge is dull or chipped, remove retaining bolts and rotate both blocks

so that two new edges come into use. Replace and tighten bolts (each block has four cutting edges)

When all four cutting edges have been used or if either block is cracked or otherwise damaged, replace both

block.

CLEANING

Caution: Wear gloves to protect hands from metal splinters. Do not use an air-gun, blasting with air can cause

metal ling and/or dust to get into eyes and respiratory system.

Disconnect the unit and wipe or brush away all dirt and metal lings. Pay particular attention to the lower half

of the piston, where dirt is more easily accumulated.