E

A50000-0

HOW TO USE THIS MANUAL

MANUAL FORMAT

This manual provides the mechanic with descriptions of the operations of disassembly,

repair, assembly, adjustment and inspection, each of which is presented in a sequential, step-

by-step procedure.

To assist you to find your way about this manual, the Section Title and Major Heading is

given at the head of every page.

An Index to contents is provided on the first page of each section.

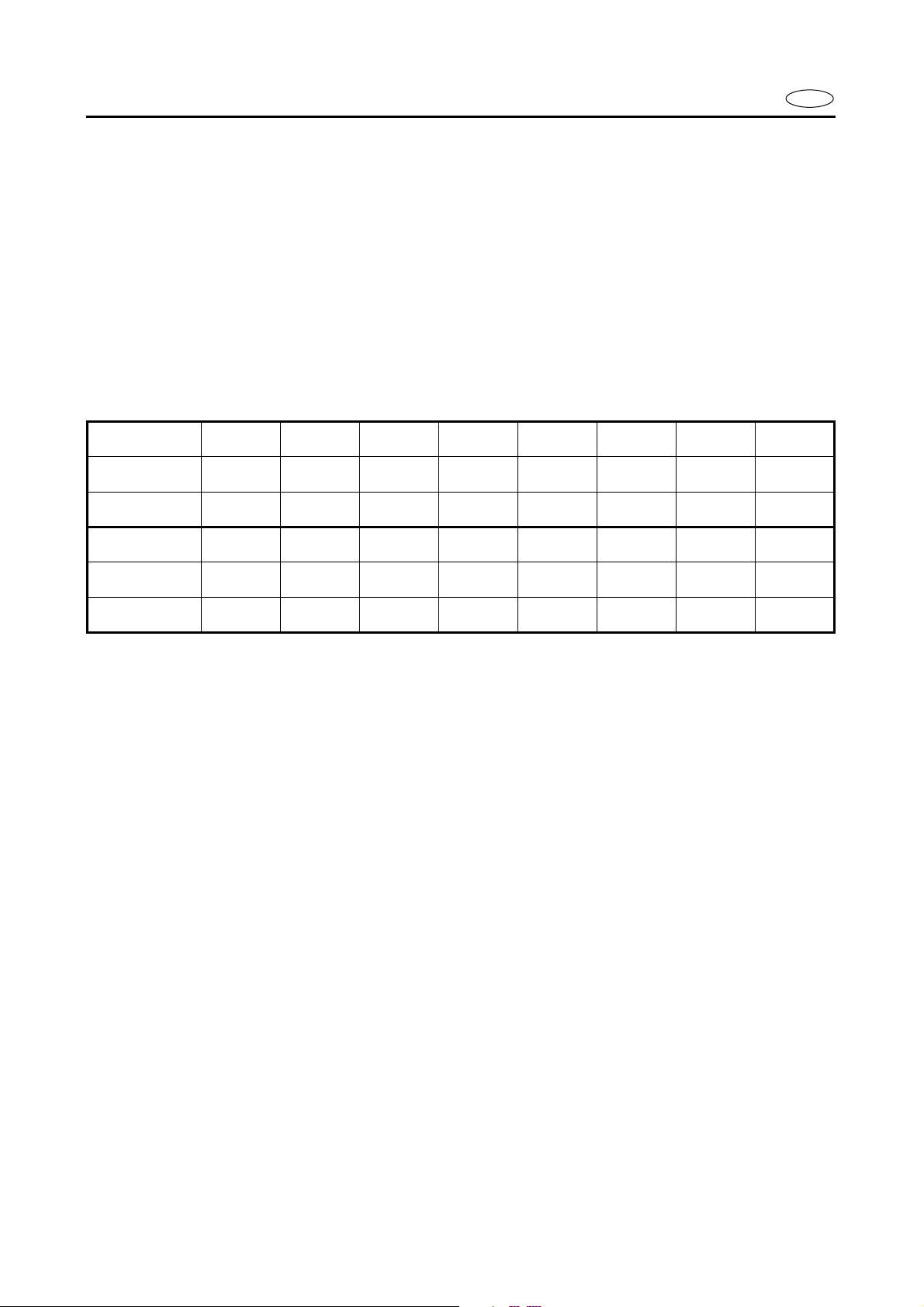

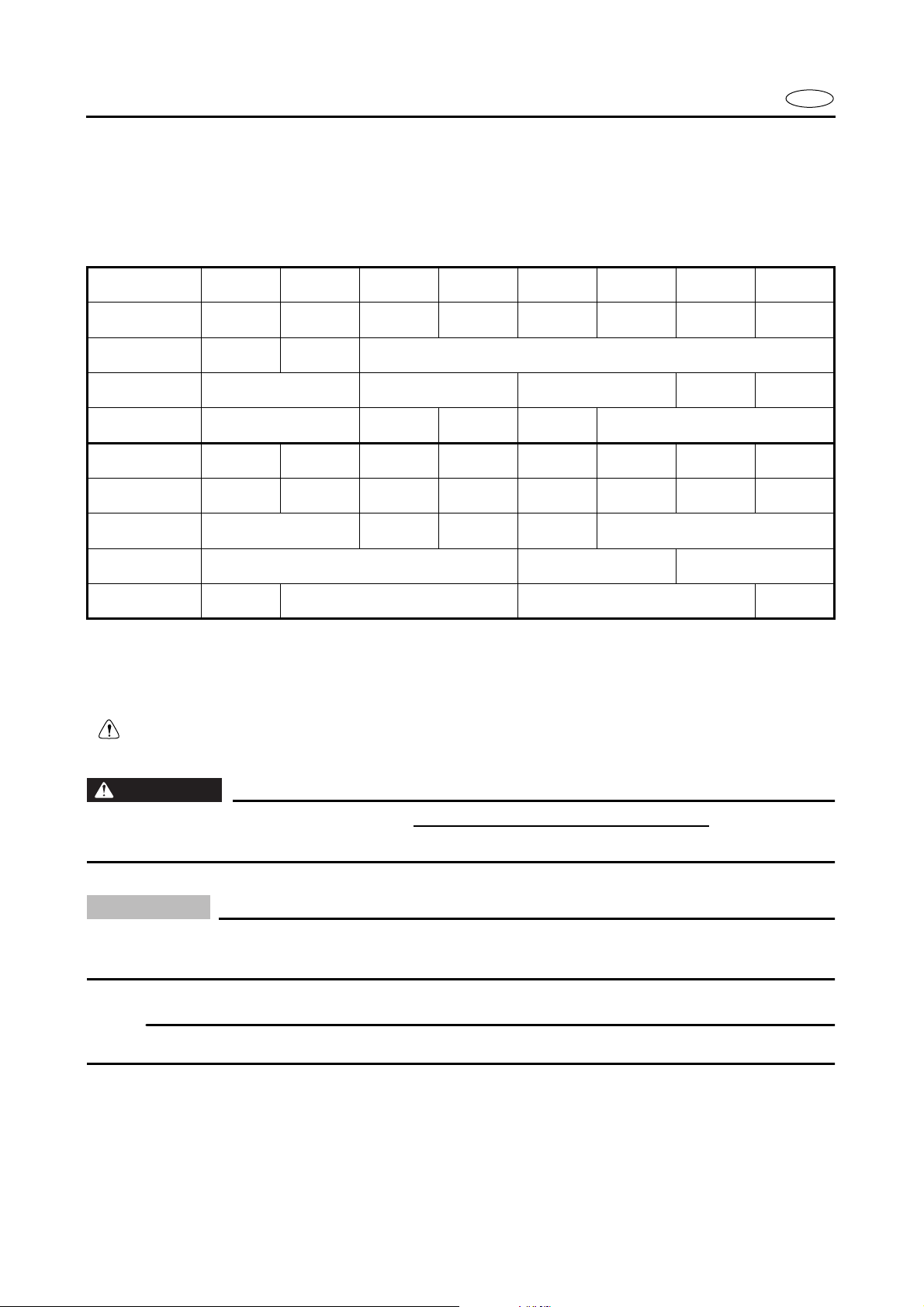

MODEL INDICATION

Multiple models are shown in this manual. These indications are noted as follows.

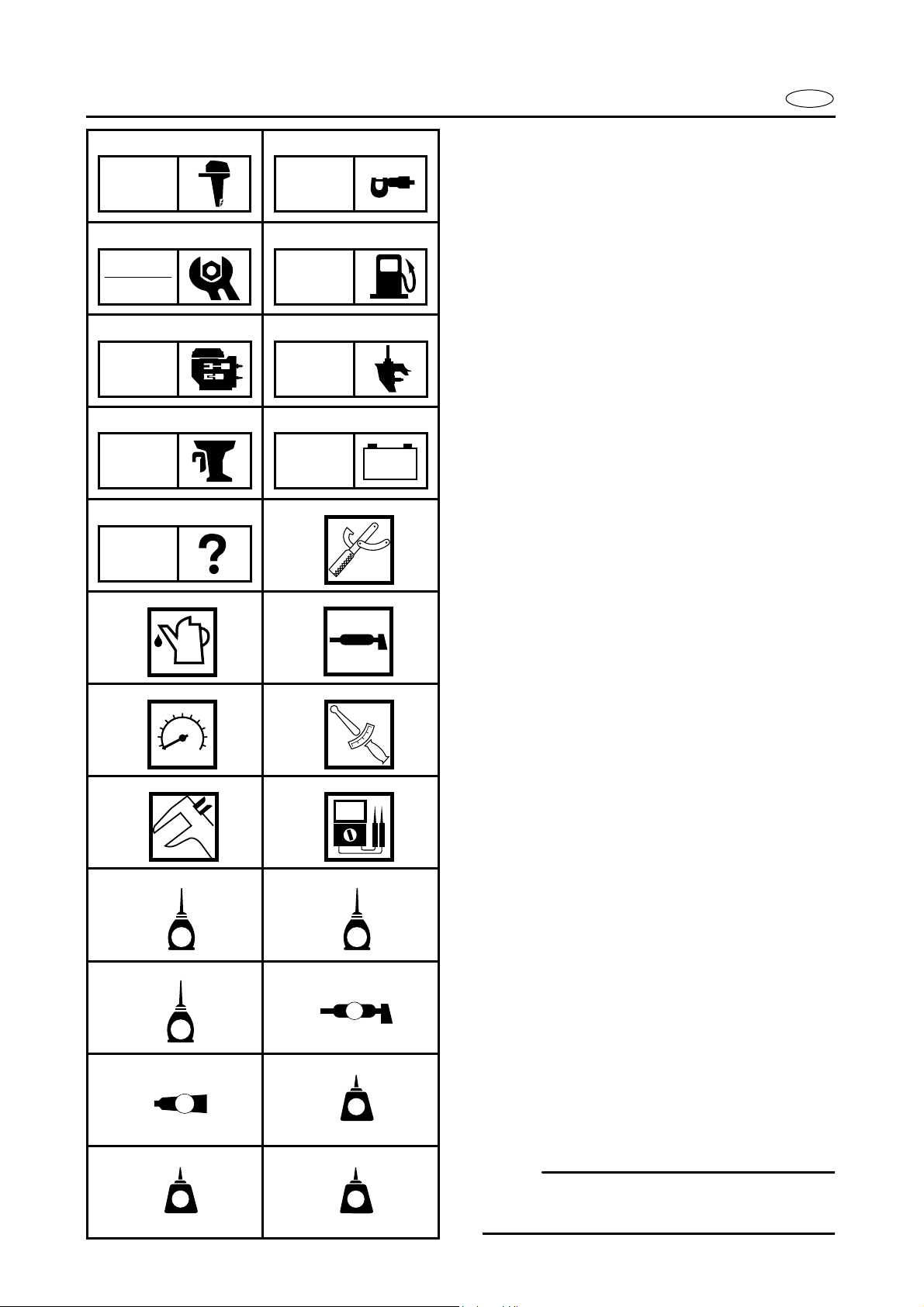

THE ILLUSTRATIONS

Some illustrations in this manual may differ from the model you have. This is because the

procedure described may relate to several models, though only one may be illustrated. (The

name of the model described will be mentioned in the description.)

To help you identify components and understand the correct procedures of disassembly and

assembly, exploded diagrams are provided. Steps in the procedures are numbered thus: 1),

2), 3). Parts shown in the illustrations are identified thus:

1

,

2

,

3

.

REFERENCES

These have been kept to a minimum, however, when you are referred to another section of

the manual, you are told the page number to go to.

Model name 50GETO 60FEHTO 60FED 60FEDO 60FET 60FETO 70BEDO 70BETO

USA and

Canada name — P60TH C60ER — C60TR — — 70TR

Indication 50GETO 60FEHTO 60FED 60FEDO 60FET 60FETO 70BEDO 70BETO

Model name 75CET 75CETO 75CEHTO 80AETO 90AEHD 90AED 90AET 90AETO

USA and

Canada name C75TR 75TR P75TH — — — C90TR 90TR

B90TR

Indication 75CET 75CETO 75CEHTO 80AETO 90AEHD 90AED 90AET 90AETO