69M3E11

GEN

INFO

1

2

3

4

5

6

7

8

9

General information

How to use this manual.................................................................................1-1

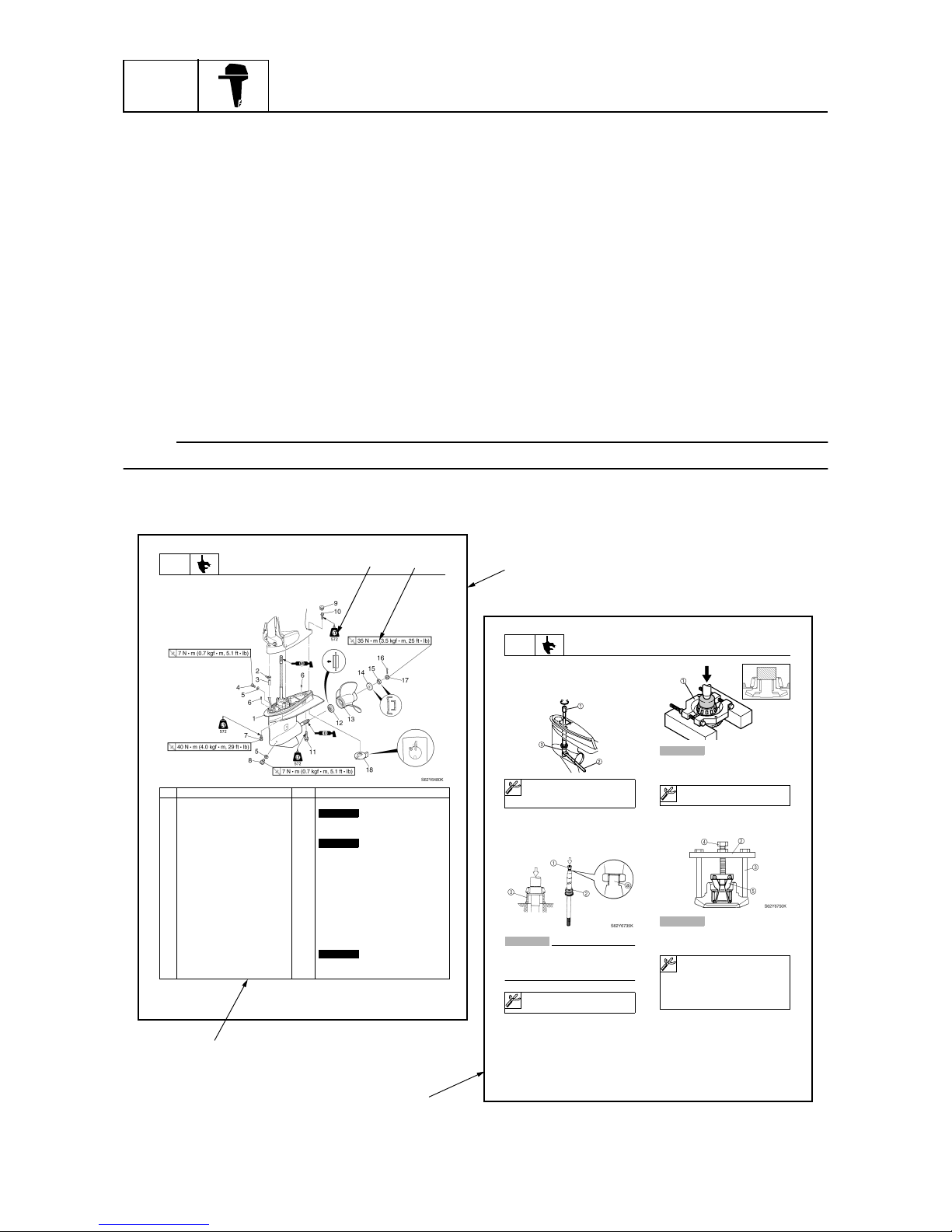

Manual format............................................................................................1-1

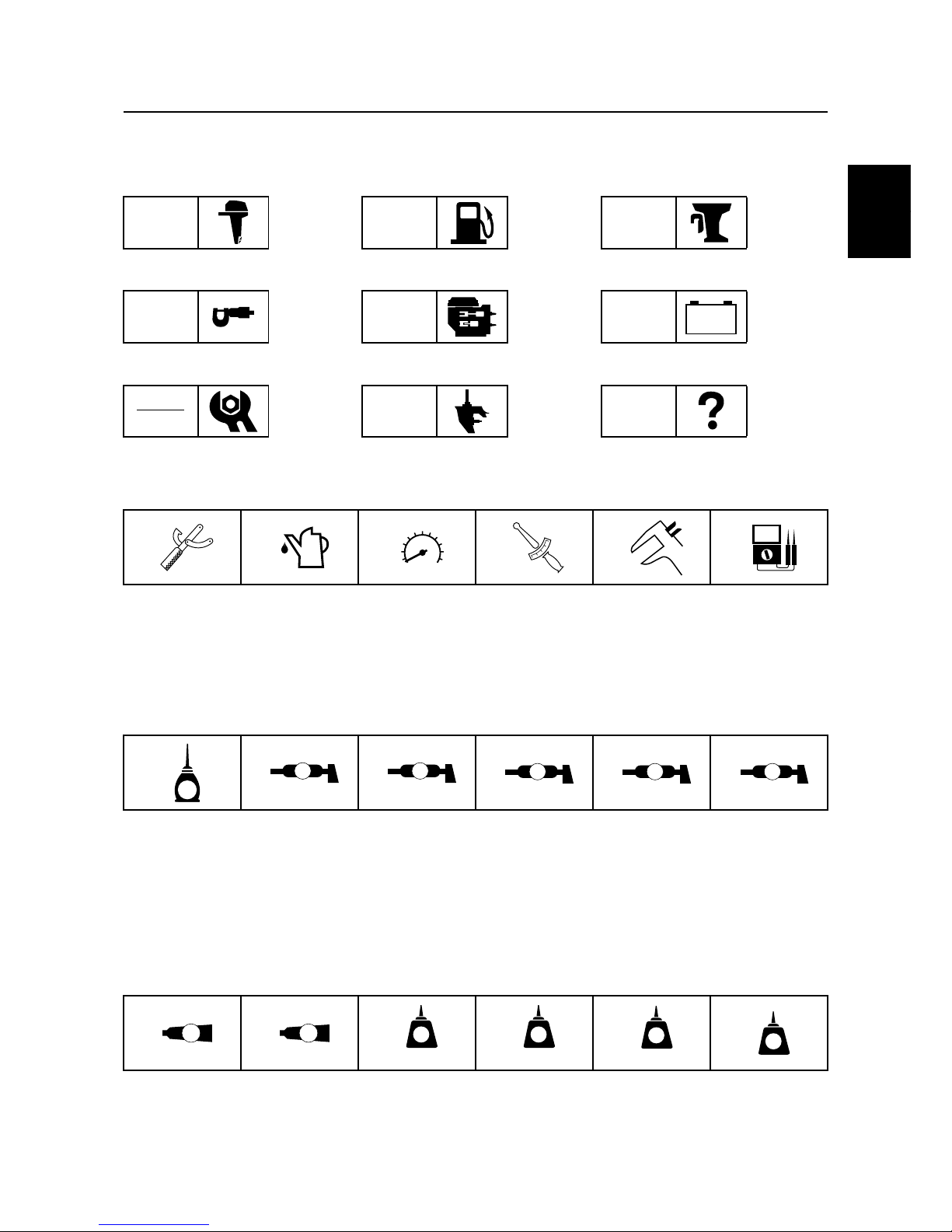

Symbols.....................................................................................................1-2

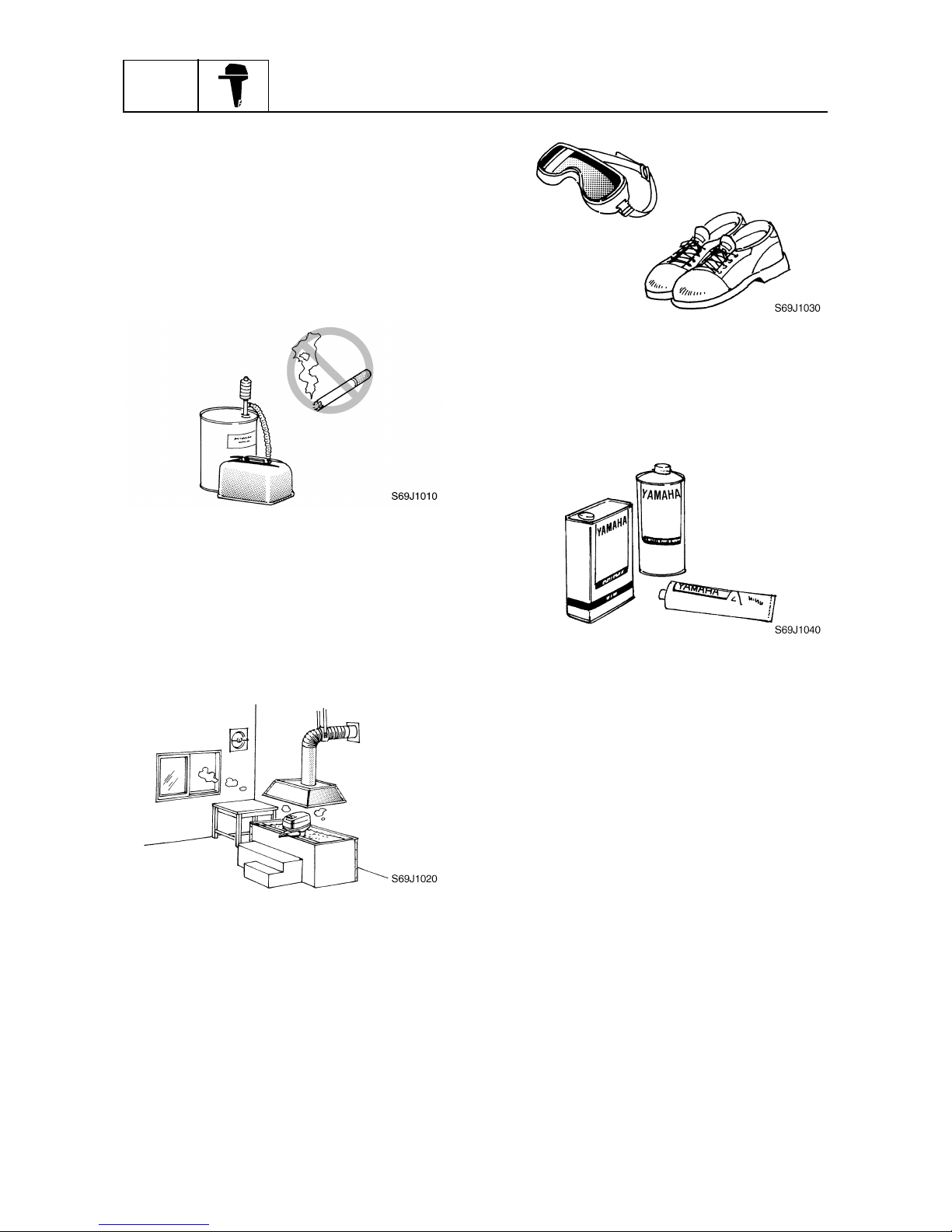

Safety while working......................................................................................1-3

Fire prevention...........................................................................................1-3

Ventilation..................................................................................................1-3

Self-protection ...........................................................................................1-3

Parts, lubricants, and sealants ..................................................................1-3

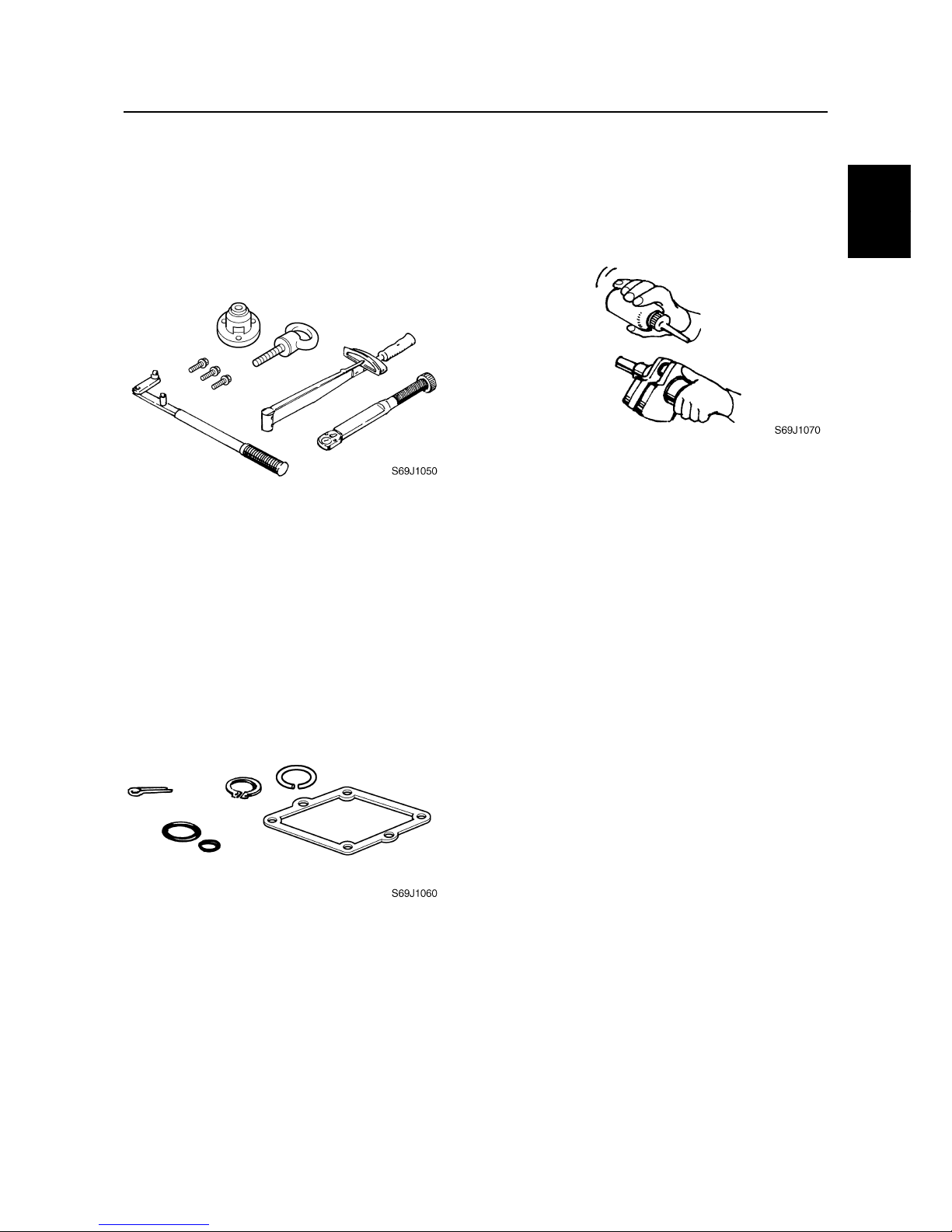

Good working practices .............................................................................1-4

Disassembly and assembly .......................................................................1-4

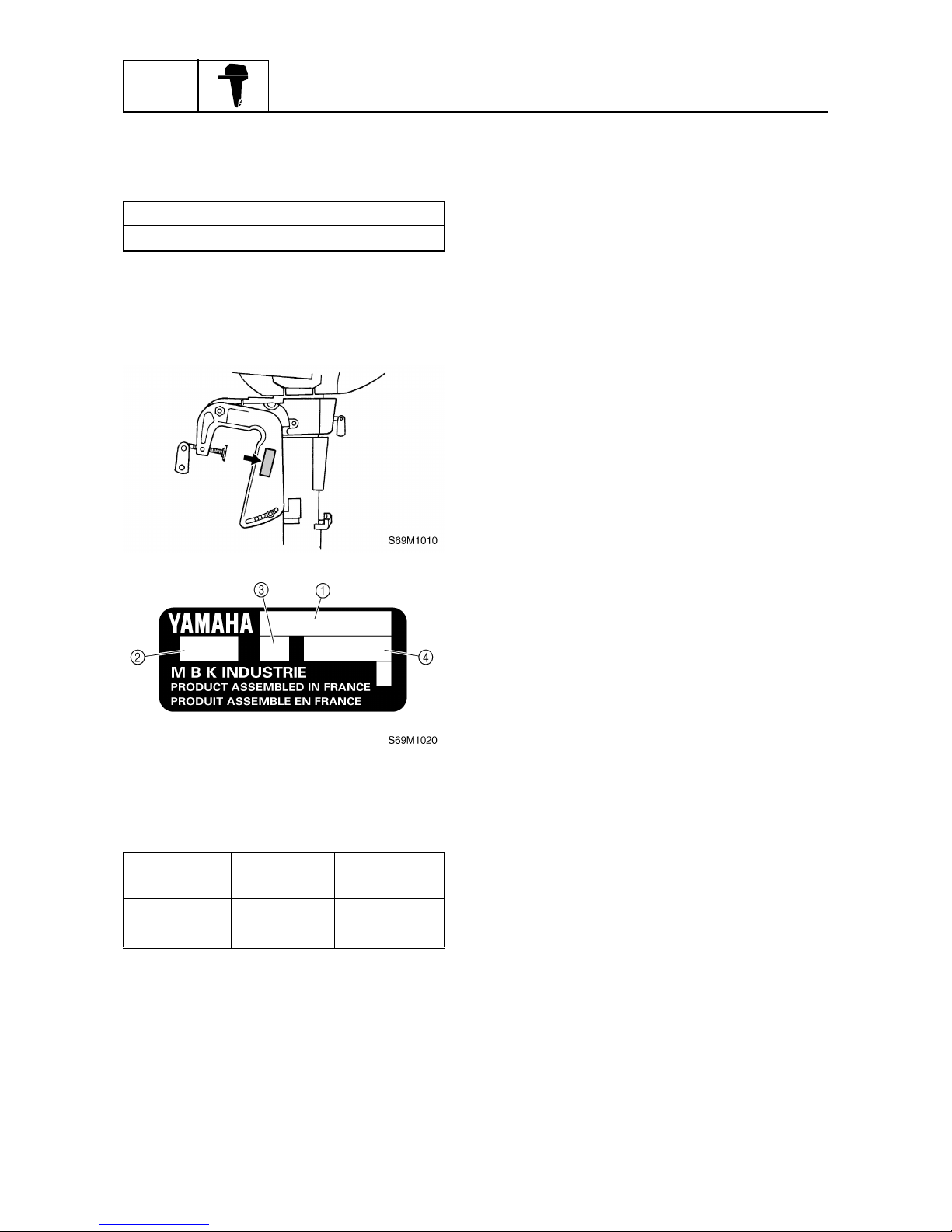

Identification...................................................................................................1-5

Applicable model .......................................................................................1-5

Serial number ............................................................................................1-5

Features and benefits....................................................................................1-6

Ignition system...........................................................................................1-6

Blowby gas reburning system....................................................................1-7

Oil check window.......................................................................................1-8

Idle silencer ...............................................................................................1-9

Splash lubrication system........................................................................1-10

Low vibration tiller handle ........................................................................1-11

Technical tips ...............................................................................................1-12

TCI system ..............................................................................................1-12

Automatic tilt support and steering pivot immobilization system .............1-13

Cooling water flow chart ..........................................................................1-14

Propeller selection.......................................................................................1-15

Propeller size...........................................................................................1-15

Selection..................................................................................................1-15

Predelivery checks ......................................................................................1-15

Checking the fuel system ........................................................................1-15

Checking the gear oil...............................................................................1-15

Checking the engine oil ...........................................................................1-16

Checking the outboard motor mounting height........................................1-16

Checking the steering system .................................................................1-16

Checking the gear shift and throttle operation.........................................1-17

Checking the engine shut-off switch........................................................1-17

Checking the cooling water pilot hole ......................................................1-17

Test run ...................................................................................................1-18

Break-in ...................................................................................................1-18

After test run ............................................................................................1-18

Adjusting the engine idle speed...............................................................1-18