69W3D1X

General information

How to use this manual.................................................................................... 1

Manual format............................................................................................... 1

Symbols........................................................................................................ 2

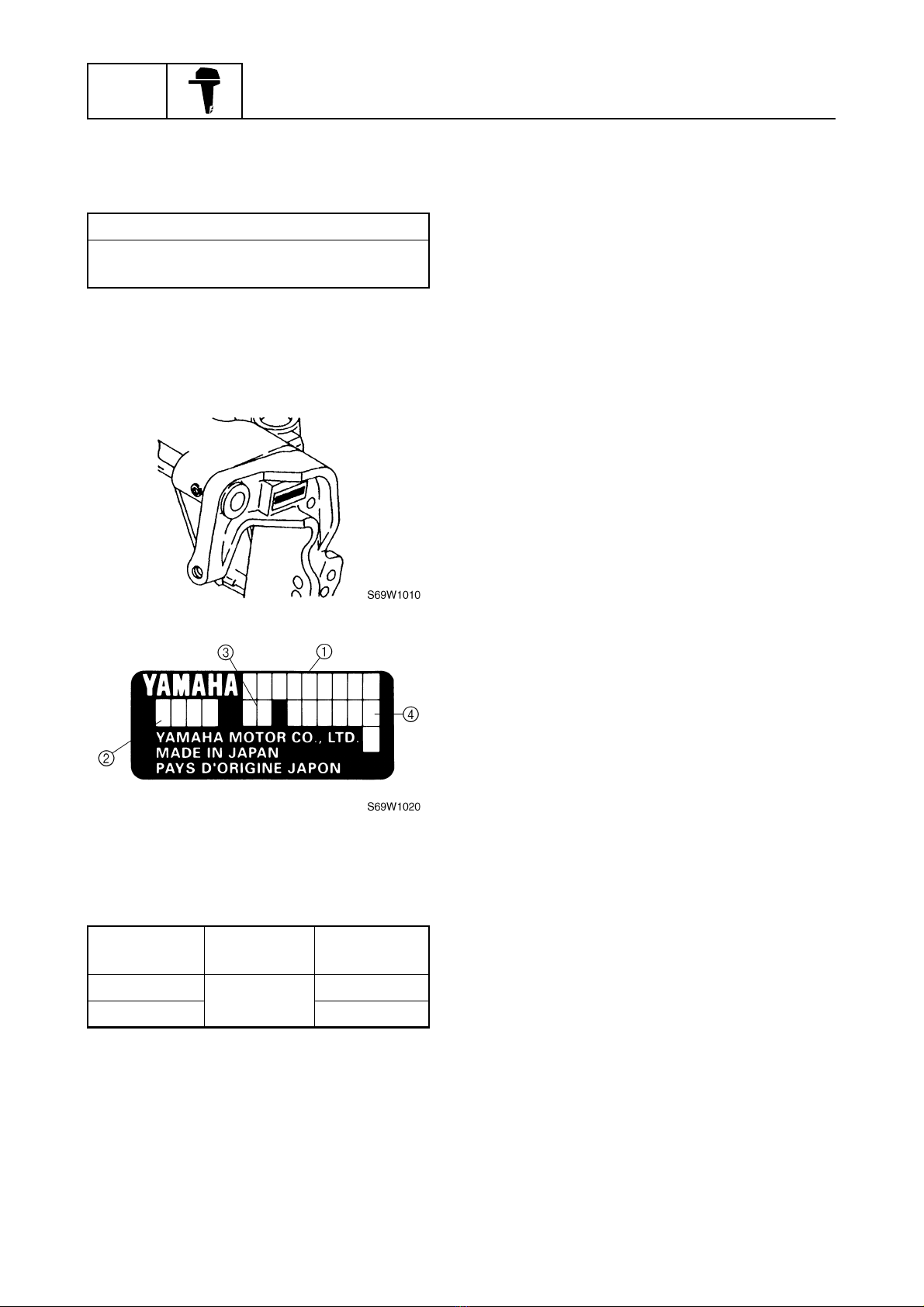

Identification...................................................................................................... 3

Applicable models ........................................................................................ 3

Serial number ............................................................................................... 3

Features and benefits....................................................................................... 4

Power unit..................................................................................................... 4

Carburetors................................................................................................... 5

Lower unit ..................................................................................................... 7

Bracket unit................................................................................................... 9

Electrical unit .............................................................................................. 10

Technical tips .................................................................................................. 11

Carburetor .................................................................................................. 11

PTT (Power Trim and Tilt) unit ................................................................... 12

Propeller selection.......................................................................................... 13

Propeller size.............................................................................................. 13

Selection..................................................................................................... 13

Predelivery checks ......................................................................................... 14

Checking the fuel system ........................................................................... 14

Checking the gear oil.................................................................................. 14

Checking the engine oil .............................................................................. 14

Checking the battery................................................................................... 14

Checking the outboard motor mounting height........................................... 14

Checking the shift/throttle cables................................................................ 15

Checking the steering system .................................................................... 15

Checking the gearshift and throttle operation............................................. 16

Checking the tilt system.............................................................................. 16

Checking the engine start switch and engine stop switch/

engine shut-off switch ............................................................................... 16

Checking the cooling water pilot hole ......................................................... 17

Test run ...................................................................................................... 17

Break-in ...................................................................................................... 17

After test run ............................................................................................... 17