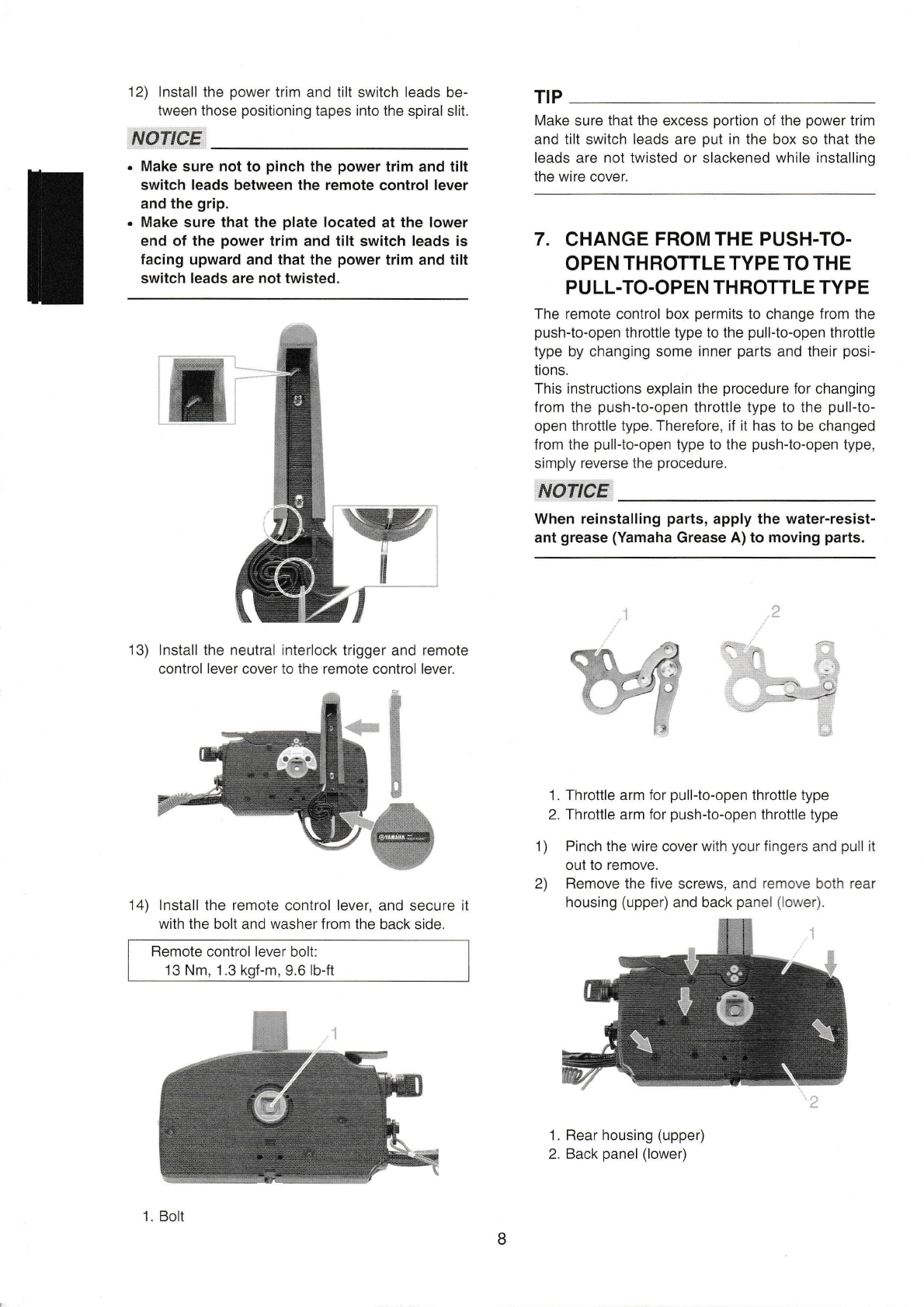

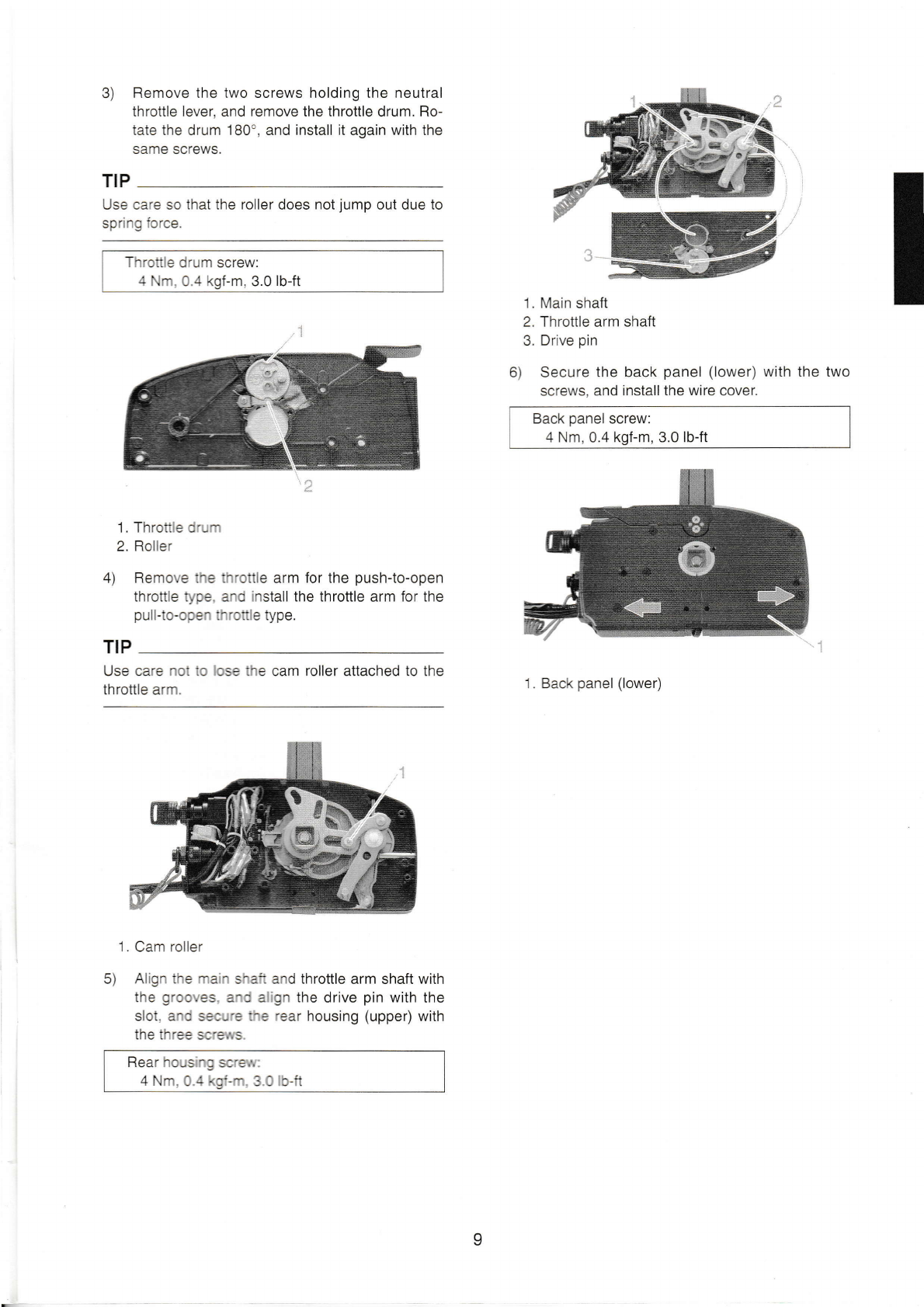

3. SAFETY FUNCTIONS

Depending on the combination of the remote control

box and engine, following function may not apply

some models. Refer to the Outboard motor Owner's

Manual for further information.

(1) Warning buzzer

The buzzer will sound if the engine overheats, the

engine oil pressure drops (4-stroke engine) or the

engine oil tank nearly empties (2-stroke engine)

which activated by the sensor installed on the en-

gine.

If the warning buzzer sounds, turn off the engine

and check the cooling water inlet and engine oil

quantity- Then, return to nearest port immedi-

ately at low speeds. Please consult your Yamaha

dealer.

(2) Neutralswitch

The neutral switch prevents the engine from start-

ing with in-gear position. When the remote control

lever is in forward or reverse, the engine cannot be

started by operating the main switch.

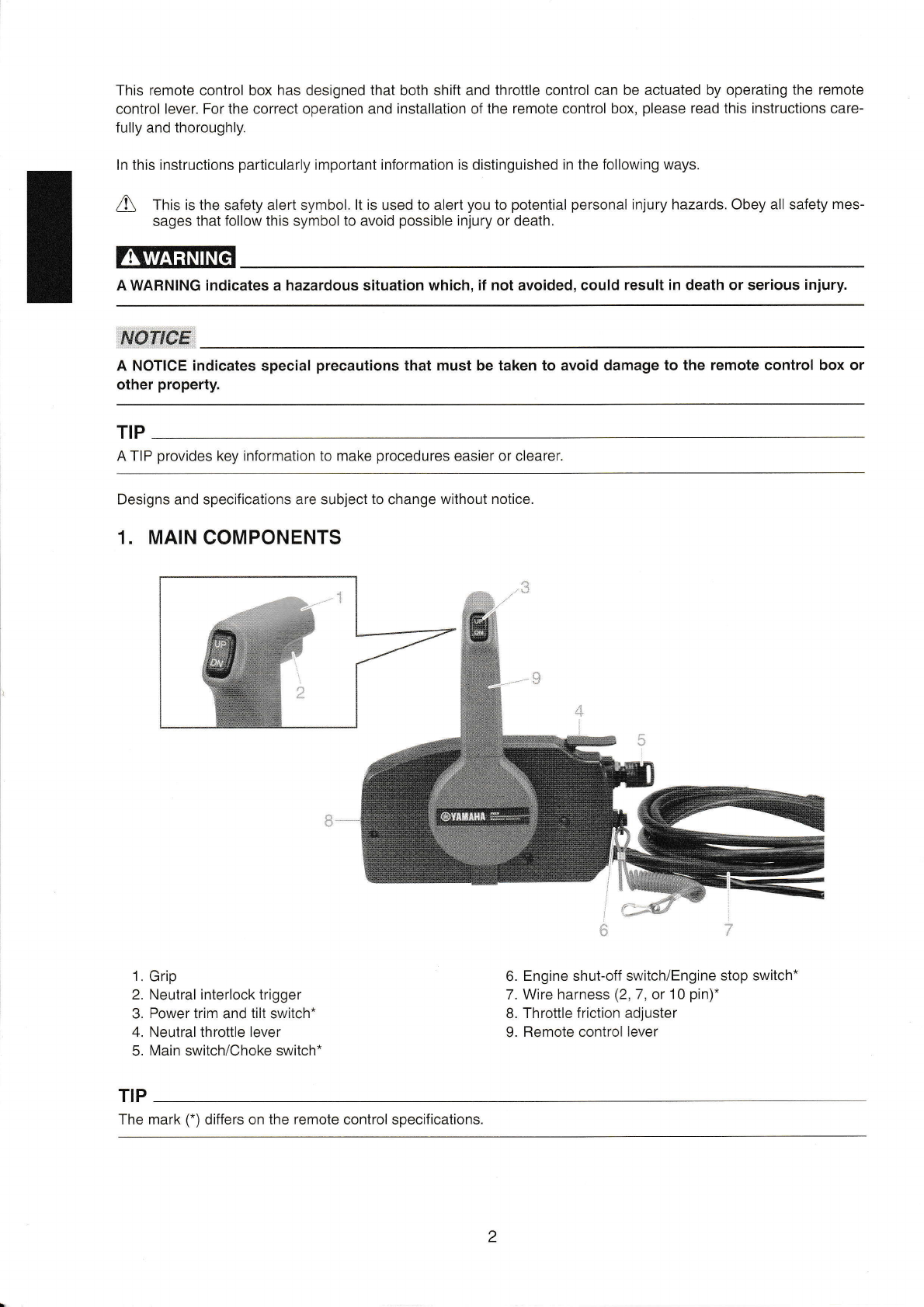

4. REMOTE CONTROL BOX

POSITIONING AND REMOTE

CONTROL CABLE LENGTH

lncorrect selection or installation of a remote

control box may reeuE in sudden and unexpect-

ed loss of eonüol, thus resulting in a serious ac-

cident. Please consutt yourYamaha dealer-

(1) Remote control box position

The remote control box should be set in a position

which it does not obstruct the operations of the re-

mote control lever and switches.

Make sure there is no obstruction on the path of the

remote control cables.

(2) Remote control cable length

Measure the distance from the "A" point (the center

of the remote control box) io the "C" point (the center

of the engine) through the "B" point (a corner of the

transom). Add 1 m (3 ft) length to make a loop in the

motor-well.

Position the remote control cables and check that

they are long enough. Connect ihe cables to the en-

gine and make sure they do not interfere with other

components when the steering is fully turned and

the engine is fulty tilted up.

Do not bend the 33C type (standard inner core)

remote eontro! cable to the 400 mm (16 in) or

less in diameter, and the 33HPC type (low-friction

inner core) remote control cable to the 300 mm

(12 in) or less in diameter.

Bending the cable sharper than this limit could

cause shorten the !ife span of the cable and

increase resistance to the movement of the re-

mote control lever.

1. Loop

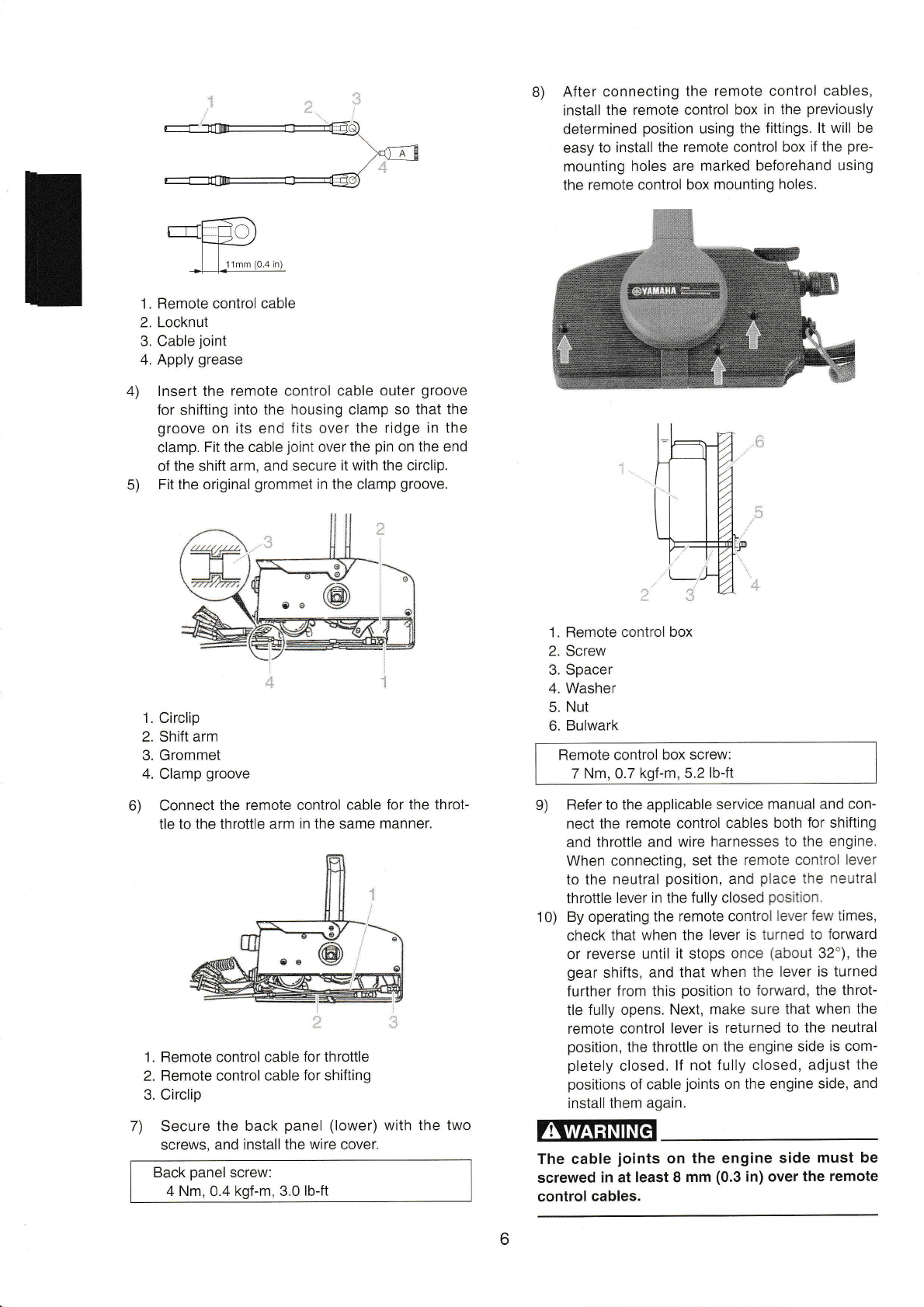

INSTALLING THE REMOTE

CONTROL CABLES

Pinch the wire cover with your fingers and pull it

out to remove.

5.

1)

1. Wire cover

2) Remove the two screws, and remove the

panel (loweO.

L

back

3)

-^/

1'

Back panel (lower)

Screw in the cable joints about 11 mm (0.4 in)

over ihe ends of the remote control cables,

and tighten the locknuts. Before installing the

cable joints, apply the water-resistance grease

(Yamaha Grease A) to the holes in the cable

joints.