4 AB-5798

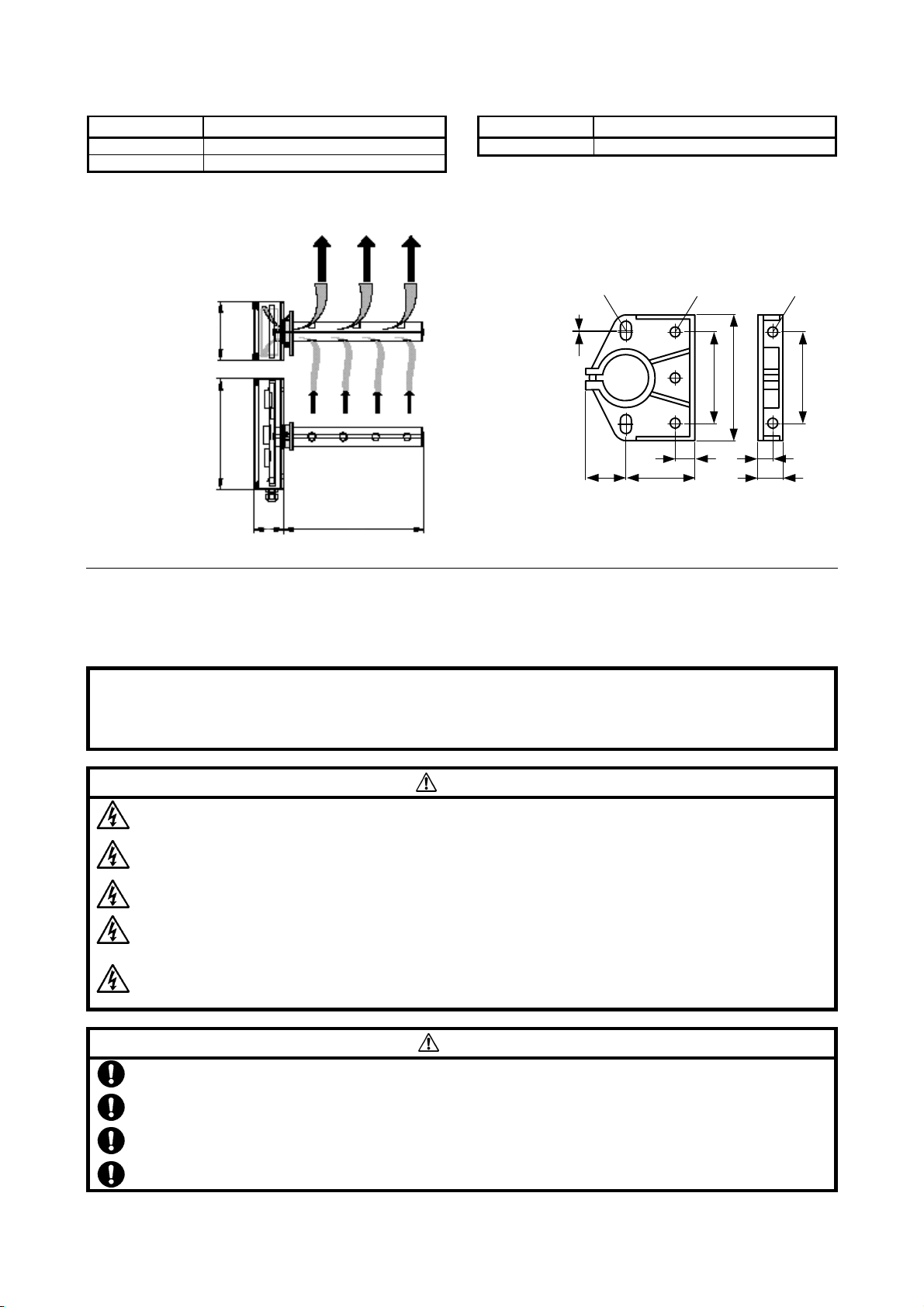

•Separate transformer

Operation check

Make sure that only the green LED starts blinking within

one minute of the power turning ON.

(During normal operation, only the green LED blinks.)

Maintenance

Periodic Calibration

We recommend calibrating the transmitter once every

year. However, determine the calibration period

according to the amount of dust or dirt in the test gas.

Calibration

1. Initial Calibration

The CO2concentration transmitter is inspected and

adjusted before it is shipped from the factory. So, it

does not need to be adjusted at the installation

site.

2. Periodic Inspection

We recommend inspecting inside the case (circuit

boards, etc.) of the CO2concentration transmitter as

test gas enters the case.

Calibration Method

The separate CO2Service Bag (procurement item No.:

83104511-001) is needed for calibrating the transmitter.

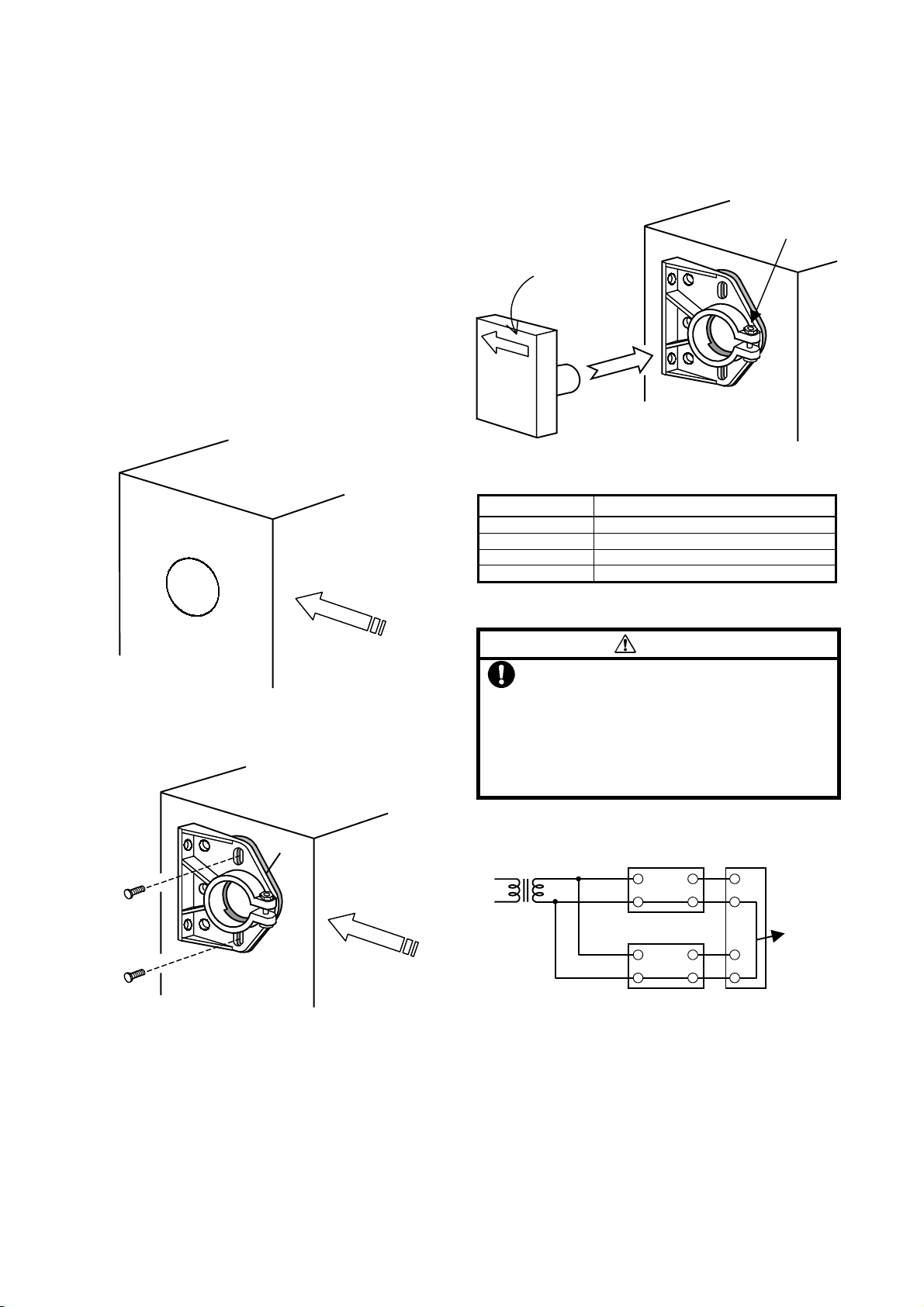

1. Remove the cover from the CO2concentration

transmitter.

2. Insert the inlet (tube tip) of the CO2Service Bag into the

CO2concentration zero gas inlet as shown in the figure

at the bottom right.

3. Turn the CO2service bag ON to start supply of CO2

concentration zero gas to the CO2concentration

transmitter.

4. With the zero gas still supplied, wait for the CO2

concentration to stabilize. (Generally, this takes about

five minutes.)

5. When CO2concentration has stabilized, calibrate the

CO2concentration transmitter. (zero adjustment

completion method using buttons)

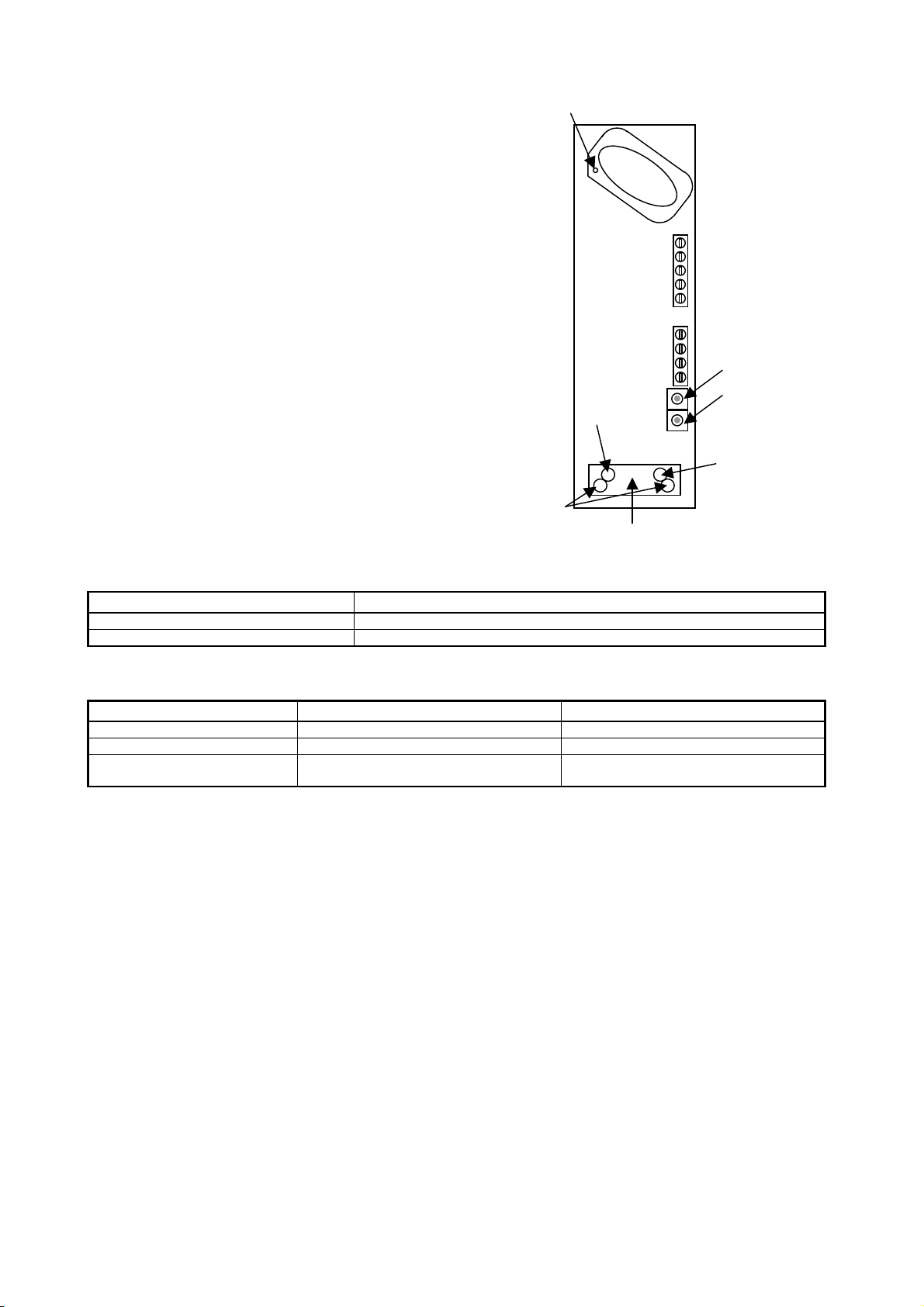

1) Simultaneously hold down the (+) and (-) buttons on

the circuit board. Hold these buttons down for

about five seconds until the yellow and red LEDs

light. This sets the CO2concentration transmitter to

the service mode. (In this state, the CO2

concentration and "OP1" are displayed alternately

on the LCD panel.)

2) Press the (+) once. The LCD panel display changes

to indicate the CO2concentration and "OP2". This

indicates that the calibration menu is entered. If

"OP2" is not displayed, press the (+) key again until

"OP2" is displayed.

3) Hold down the (-) button for about three seconds

until all LEDs (green, yellow, red) light. This starts

calibration. All LEDs light when calibration begins

and go out when calibration ends. When all LEDs

go out, this indicates that the CO2concentration

transmitter has returned to the standard

measurement mode.

IMPORTANT:

Press the (-) button at only OP2. Do not

press this button at other menu items. (If you

press the (-) button at different menu item, the

functions of the CO2concentration transmitter

are sometimes adversely affected. If you have

executed a different menu item, contact a

Yamatake service engineer.)

6. Tighten the cover of the CO2concentration transmitter.

(During this operation, do not mistake the top and

bottom of the cover. (If you do so, the arrow will face

the opposite direction.))

To return to the user mode from the service mode

without calibrating the CO2concentration transmitter,

repeatedly press the (+) button to advance the service

mode one menu item at a time. Advance the mode

"OP1" →"OP2" →"OP3" →"OP4" →"OP5" →

"OP6" →and press the (+) button again to return to the

user mode.

Y

24 VAC +

-

~

⊥ ⊥

Multi-loop

controller

Y+

-

~

⊥ ⊥

24 VAC

○GOOD

No common loop formed