YZ-X2

●Do not use the machine where the inclination exceeds the rated

value of the machine.

●Please do not smoke while charging the battery.

●Do not use the machine in a very dirty area. If the road garbage is

thick, please repeat the sweeping work twice or more.

●The machine should be in temperature between -10℃to 40℃.

●When using the machine, the temperature should be between -10

°C and 40°C, and the humidity should be between 30% and 95%.

●Do not use the machine as a means of transportation.

● When the machine is not moving forward, do not let the brush

continue to rotate to avoid damage to the ground.

●In case of fire, please remember to use powder fire extinguisher

instead of water.

●When the machine operation fails, make sure that the failure is not

caused by lack of regular maintenance.

●If some parts need to be replaced, you can buy spare parts from

the original manufacturer or authorized dealer.

● Confirming that the machine is in proper operation and safe

condition, professionals or service center must work in accordance

with the maintenance section of this manual.

●Even if the machine is to be dismantled and scrapped, someone

should be there to pay attention. Because some harmful

substances (such as batteries, waste oil, etc.) have met the

standards, they should be sent to a specific center for processing.

1.3 Safety requirements for batteries

●It must be avoided that the battery is in a low voltage state, and

the battery should be charged as soon as possible when the

voltage is about 21V.

●To avoid leakage of electricity, please keep the battery dry and

clean, especially to remove contaminants such as metal dust.

●It is forbidden to put metal parts (such as tools) on the battery to

prevent the battery from being short-circuited and burnt out.

●The charging room should be well ventilated.

●Do not connect or remove the battery when the key switch is in

the ON position.

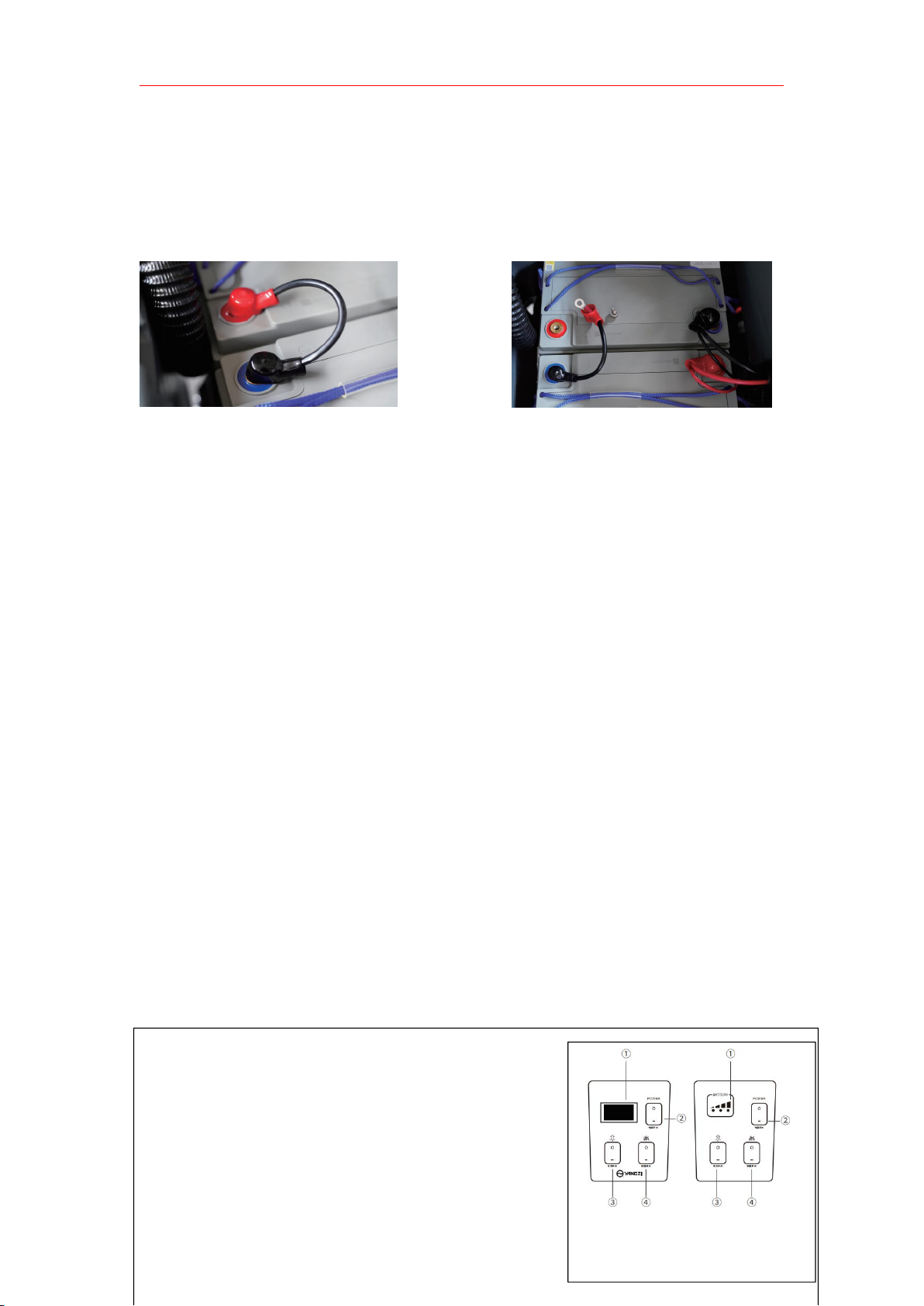

●Before removing or installing batteries, first disconnect the

negative (-) battery wire, and then disconnect the positive (+)