Features

__________________________________________________________________

Clean Emissions

Building off the proven TNE design, Yanmar has

achieved superior exhaust emissions by improving the

combustion chamber and fuel injection equipment

design. Engines are compliant with EPA Tier 3 and EU

stage III A exhaust emissions regulations.

Reliable and Durable

The TNV engines now proudly take up the running as

Yanmar’s premium small industrial diesel. They offer

even more enhanced durability due to better block

cooling, a stiffer crank and pistons, finer tolerance in the

journal, and more. CAE analysis has brought lower

vibrations and higher strength to the mounting structure

for even better reliability in heavy-duty jobs.

Fuel Delivery and Economy

A newly designed, electronically governed MP type fuel

injector pump is utilized to assure more precise fuel

delivery and control. The result is reduced emissions,

improved performance over a wide range of applications

and good fuel economy which assures that Yanmar’s

reputation for superior starting characteristics continues.

Noise Level Reduction

Yanmar’s original CAE techniques have optimized the

stiffness, minimized transformation, and reduced radiant

noise in the cylinder block. Gear noise reduction is

achieved through an improved gear tooth profile

resulting in less mechanical noise.

Additional Information

Yanmar America Corp Distributed By:

951 Corporate Grove Drive

Buffalo Grove, IL 60089

www.yanmar.com

Standard Engine Equipment

__________________________________________________________________

General

Intake & Exhaust Manifold

Muffler/Exhaust Pipe Gasket (shipped loose)

Lubrication System

11.2 L Capacity Deep, Side Drain Oil Pan

Trochoid Oil Pump

Paper Element Oil Filter

Oil Pressure Switch

Electrical System

12V, 40 Amp Alternator

12V Starter Motor

12V, 500W Air Heater

Preheat Relay (shipped loose)

Fuel System

Electronically Governed MP4 Fuel Injection Pump

12V Electric Fuel Pump (shipped loose)

Paper Element Fuel Filter

Water Separator (shipped loose)

Cooling System

Water Pump, Belt Driven

6-Blade, 430mm Cooling Fan—Pusher Type

71º C (160º F) Thermostat

Fan Belt

Power Take Off

Flywheel, SAE 11 1/2”

Flywheel Housing, SAE #3 (125 mm deep)

4TNV98T-ZGGE General Specification

67.7 HP (50.4 kW) @ 1800 rated rpm*

______________________________________________________________________________________________

Type• • • 4 Cylinder, 4-Cycle, Liquid Cooled Diesel Engine

Bore • • • • • • • • • • • • • • • • • • • • • • 98 mm

Stroke • • • • • • • • • • • • • • • • • • • • • 110 mm

Displacement • • • • • • • • • • • • • • • • • 3.319 L

Aspiration • • • • • • • • • • • • • • • Turbocharged

Combustion System • • • • • • • • • • Direct Injection

Rotation (from flywheel end) • • • • • • Counterclockwise

Dry Weight • • • • • • • • • • • • • 605 lbs (275 kg)

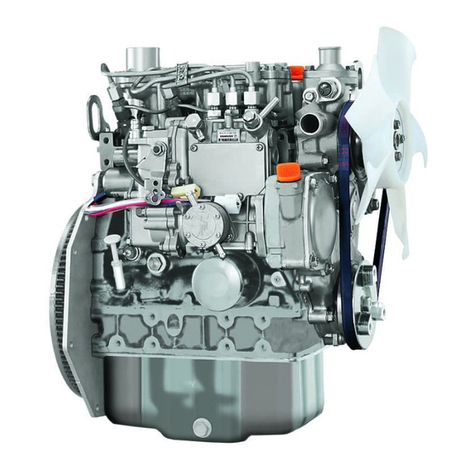

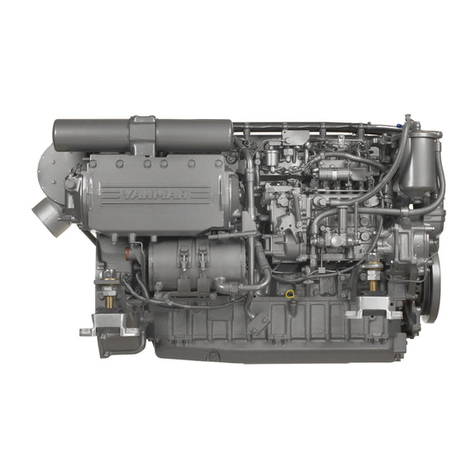

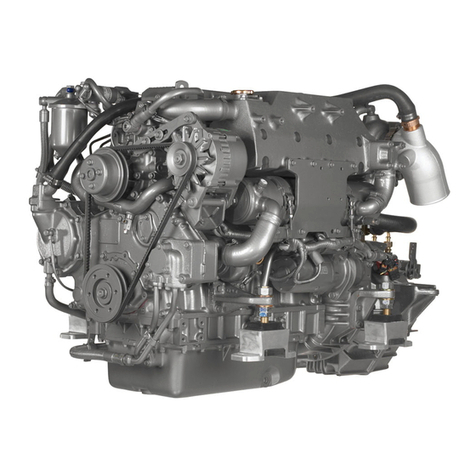

TNV DI Series

Industrial Diesel Engine

___________________________________________________________________________________________________________

___________________________________________________________________________________________________________

Page 1 of 2

Image shown may not be actual engine