2 | RMB/ENERGIE GmbH

Operation manual CHP 5.0 - 30.0 | Status 01.2020

Contents

1. Document information .................. 4

1.1 Validity . . . . . . . . . . . . . . . . . . . . . .4

1.2 Supporting documents . . . . . . . . . . . . . 4

1.3 Safety instructions. . . . . . . . . . . . . . . .5

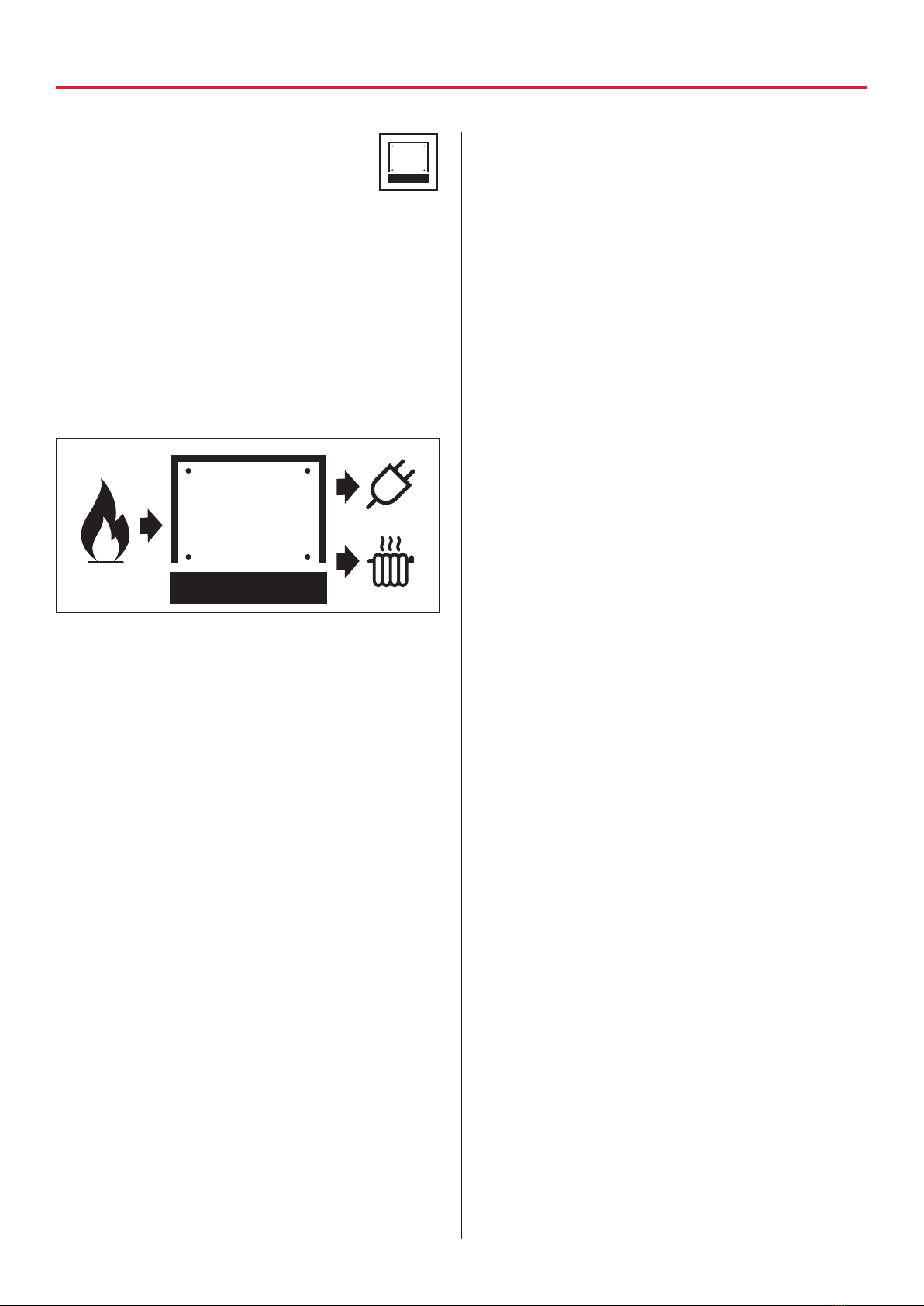

1.4 Explanation of symbols . . . . . . . . . . . . . 5

2. Safety information...................... 6

2.1 Intended use . . . . . . . . . . . . . . . . . . 6

2.2 Authorised target groups . . . . . . . . . . . . 6

2.2.1 Manufacturer.................... 6

2.2.2 Operator ....................... 6

2.2.3 Trained personnel ................ 6

2.2.4 User .......................... 6

2.3 General safety instructions . . . . . . . . . . . 7

3. Product information .................... 8

3.1 Functional principle . . . . . . . . . . . . . . . 8

3.2 Registering with the energy provider . . . . . . 8

3.3 Modes of operation . . . . . . . . . . . . . . . 8

3.3.1 Ready for e-car charging button ..... 8

3.3.2 Summer operation ............... 8

3.3.3 Heat-optimised .................. 8

3.3.4 Electricity-optimised .............. 8

3.3.5 Shutdown ...................... 8

3.4 Safety devices. . . . . . . . . . . . . . . . . .9

3.5 Product variants . . . . . . . . . . . . . . . . .9

3.6 Product overview . . . . . . . . . . . . . . . 10

3.6.1 Generation unit CHP 5.0 - 7.2 ..... 10

3.6.2 Generation unit CHP 11.0 - 20.0 ... 10

3.6.3 Generation unit CHP 25.0 - 30.0 ....11

3.6.4 Control cabinet ..................11

3.6.5 Modem ........................11

3.6.6 Expansion tank connection block ... 12

3.6.7 MSM adapter magnetic filter

(“MSM filter”)................... 12

3.7 Scope of supply . . . . . . . . . . . . . . . . 12

4. Storage.............................. 13

5. Assembly ............................ 14

5.1 Safety instructions for assembly . . . . . . . 14

5.2 Installation location requirements . . . . . . . 14

5.2.1 Overview of the installation location . 14

5.2.2 Installation room ................ 15

5.2.3 Heating system ................. 16

5.2.4 Flue gas routing ................ 16

5.2.5 Exhaust air duct ................ 16

5.2.6 Supply air supply ............... 16

5.2.7 Gas supply .................... 17

5.2.8 Water supply ................... 17

5.2.9 Condensate drain ............... 17

5.2.10 Power supply .................. 17

5.2.11 Reactive current compensation .... 17

5.2.12 Mobile communications network.... 17

5.3 Assembly steps . . . . . . . . . . . . . . . . 18

5.3.1 Preparing for assembly........... 18

5.3.2 Unpacking the system ........... 18

5.3.3 Positioning the generation unit ..... 19

5.3.4 Screwing the control cabinet in

position ....................... 20

5.3.5 Screwing the expansion tank

connection block in position ....... 20

5.3.6 Connecting the generation unit..... 20

5.3.7 Connecting the temperature sensors 24

5.3.8 Connecting the modem........... 24

5.3.9 Connecting the control cabinet ..... 25

5.3.10 Checking the connections......... 25

5.4 Test run . . . . . . . . . . . . . . . . . . . . 26

5.4.1 Opening the generation unit ....... 26

5.4.2 Preparing the expansion tank

connection block ................ 26

5.4.3 Replenishing the cooling water..... 26

5.4.4 Starting the test run ............. 27

5.4.5 Checking the system ............ 27

5.4.6 Stopping the test run. . . . . . . . . . . . . 28

5.4.7 Closing the generation unit........ 28

6. Commissioning ....................... 29

Contents