YASKAWA Varispeed-656DC3 User manual

Other YASKAWA Media Converter manuals

YASKAWA

YASKAWA CR700 User manual

YASKAWA

YASKAWA CIMR-MX1S User manual

YASKAWA

YASKAWA D1000 Series User manual

YASKAWA

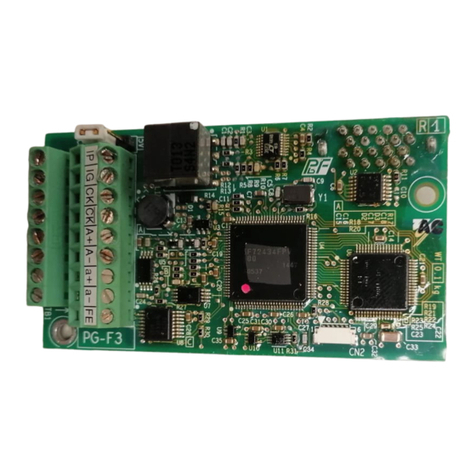

YASKAWA PG-F3 User manual

YASKAWA

YASKAWA PROFINET V1000 User manual

YASKAWA

YASKAWA CIMR-ACA4011 User manual

YASKAWA

YASKAWA U1000 Series User manual

YASKAWA

YASKAWA VS-505WII User manual

YASKAWA

YASKAWA CIMR-DC4A0040AAA User manual

YASKAWA

YASKAWA MECHATROLINK-III User manual