MOTO

MAN

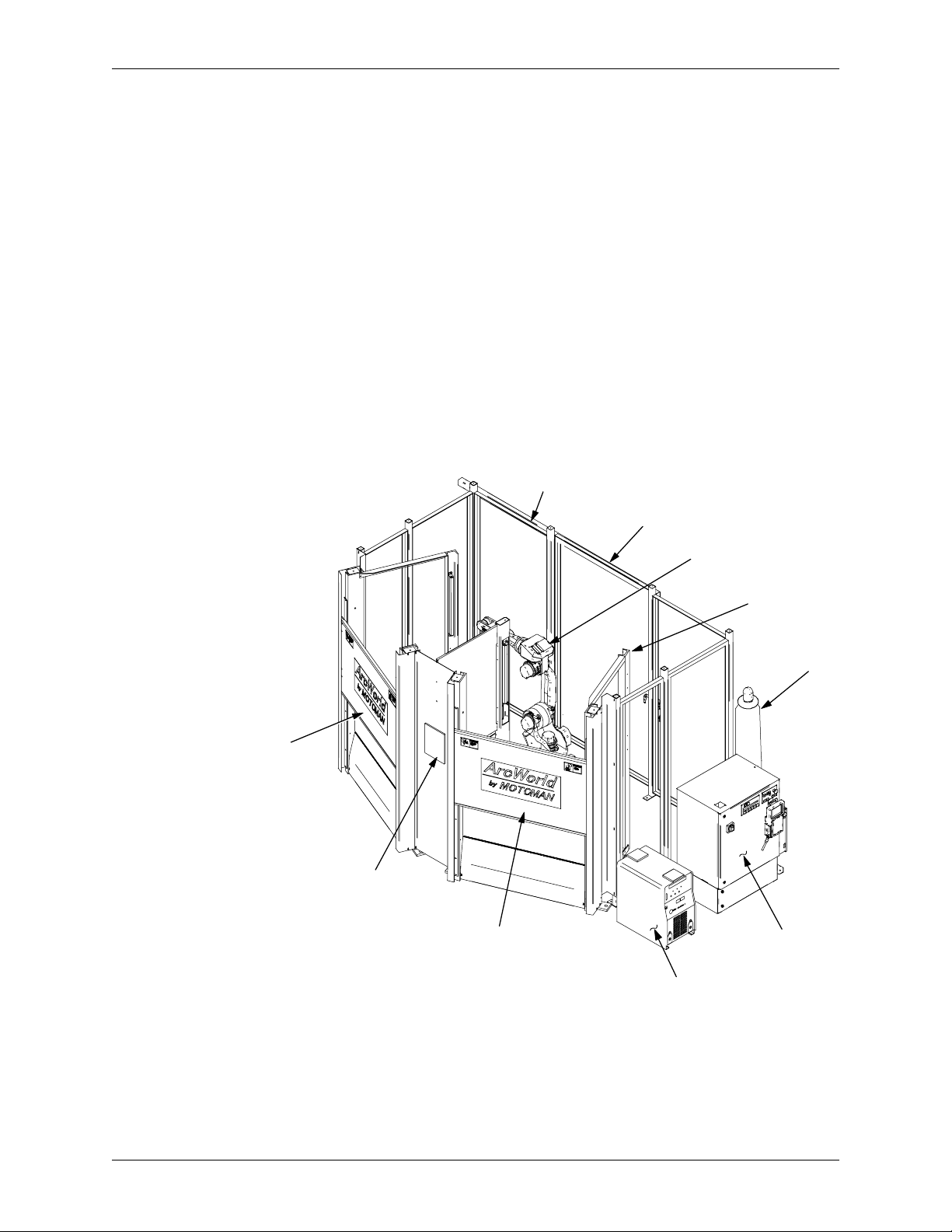

i ArcWorld II-200 System Manual

TABLE OF CONTENTS

Section Page

LIST OF FIGURES...........................................................................................................................iii

LIST OF TABLES ............................................................................................................................iii

1 INTRODUCTION

1.1 About this Document....................................................................................................1-1

1.2 System Overview ..........................................................................................................1-2

1.2.1 System Layout ................................................................................................1-2

1.2.2 Major Components .........................................................................................1-3

1.2.3 Optional Equipment ........................................................................................1-3

1.3 Reference to Other Documentation................................................................................1-3

1.4 Customer Service Information ......................................................................................1-4

2 SAFETY

2.1 Introduction..................................................................................................................2-1

2.2 Standard Conventions ..................................................................................................2-2

2.3 General Safeguarding Tips............................................................................................2-3

2.4 Mechanical Safety Devices ...........................................................................................2-3

2.5 Installation Safety .........................................................................................................2-4

2.6 Programming Safety.....................................................................................................2-4

2.7 Operation Safety ...........................................................................................................2-5

2.8 Maintenance Safety.......................................................................................................2-6

3 EQUIPMENT DESCRIPTION

3.1 UP-series Robot Description ........................................................................................3-1

3.2 XRC 2001 Controller ....................................................................................................3-1

3.2.1 Playback Panel ...............................................................................................3-2

3.2.2 Programming Pendant ....................................................................................3-3

3.2.3 Brake Release .................................................................................................3-6

3.3 Operator Station............................................................................................................3-6

3.3.1 Cycle Start ......................................................................................................3-6

3.3.2 AUTO/MANUAL ..............................................................................................3-7

3.3.3 Emergency Stop (E-STOP) ..............................................................................3-7

3.4 Barrier Assembly ..........................................................................................................3-7

3.4.1 Stationary Weld Tables ...................................................................................3-7

3.5 Safety Features .............................................................................................................3-8

3.5.1 Arc Screens ....................................................................................................3-8

3.5.2 Fencing ...........................................................................................................3-8

3.5.3 Emergency Stops (E-STOPS) ..........................................................................3-8

3.5.4 ENABLE Switch ...............................................................................................3-9

3.5.5 Interlocked Cell Door ......................................................................................3-9

3.5.6 Light Curtains .................................................................................................3-9

3.5.7 Brake Release .................................................................................................3-9