5.6.

CONGRATULATIONS ON

YOUR PURCHASE OF A

NEW YETI.

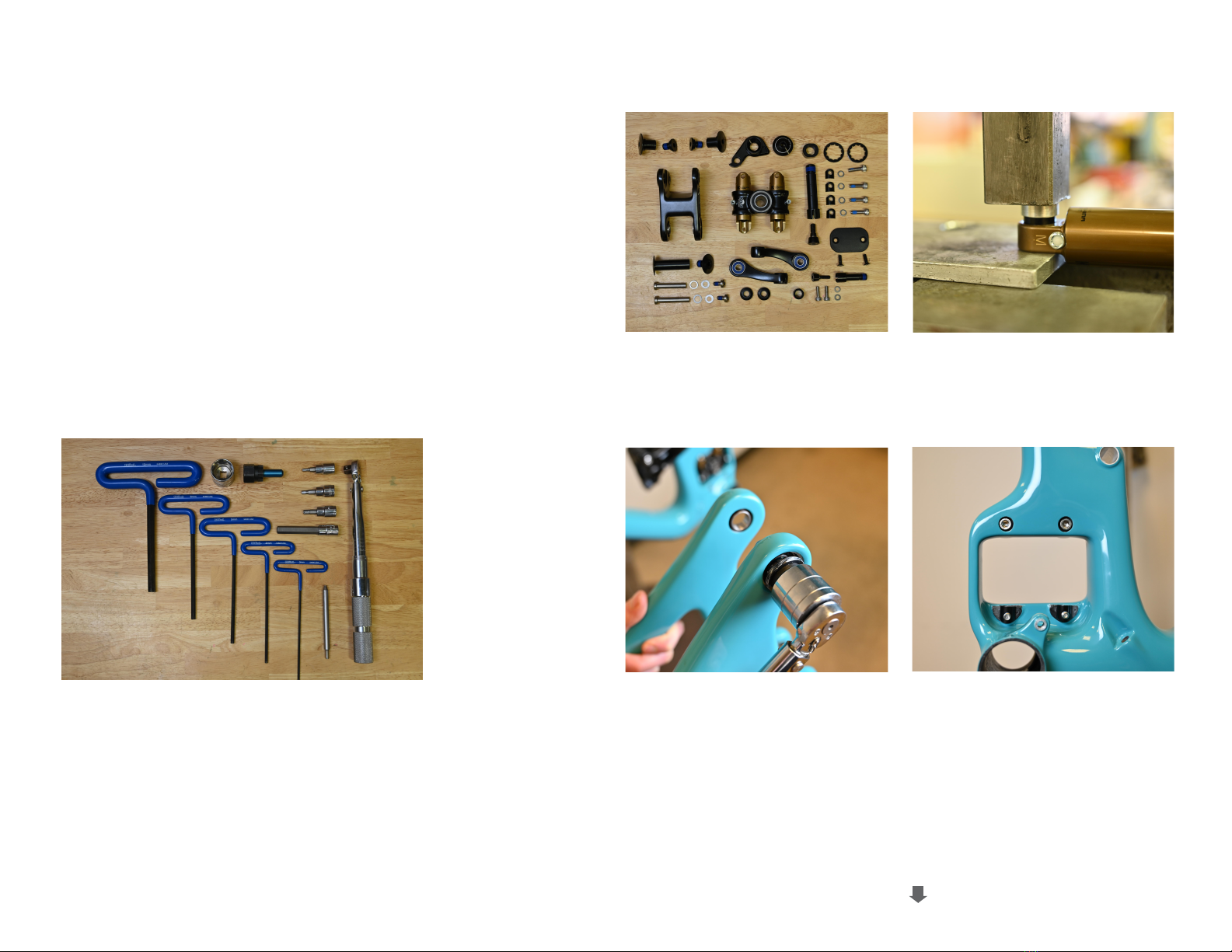

We are confident your new bicycle will

exceed your expectations for value,

performance, and ride quality. Each

frameset and component has been custom

specified and designed to enhance your

riding experience. Whether you are a

beginner cyclist, or a seasoned pro, your Yeti

bicycle will provide endless hours of two-

wheeled fun.

This model specific manual is designed to

be used in conjunction with the general Yeti

Owner’s Manual and the manuals supplied

by the suspension manufacturers. If you did

not receive the Yeti owner’s manual or the

manual provided by the suspension

manufacturer, download the materials off

the Internet, or contact your local dealer.

Bicycling can be a hazardous activity

even under the best of circumstances.

Proper maintenance of your bicycle is your

responsibility and when done properly helps

reduce the risk of injury and damage to your

bicycle.

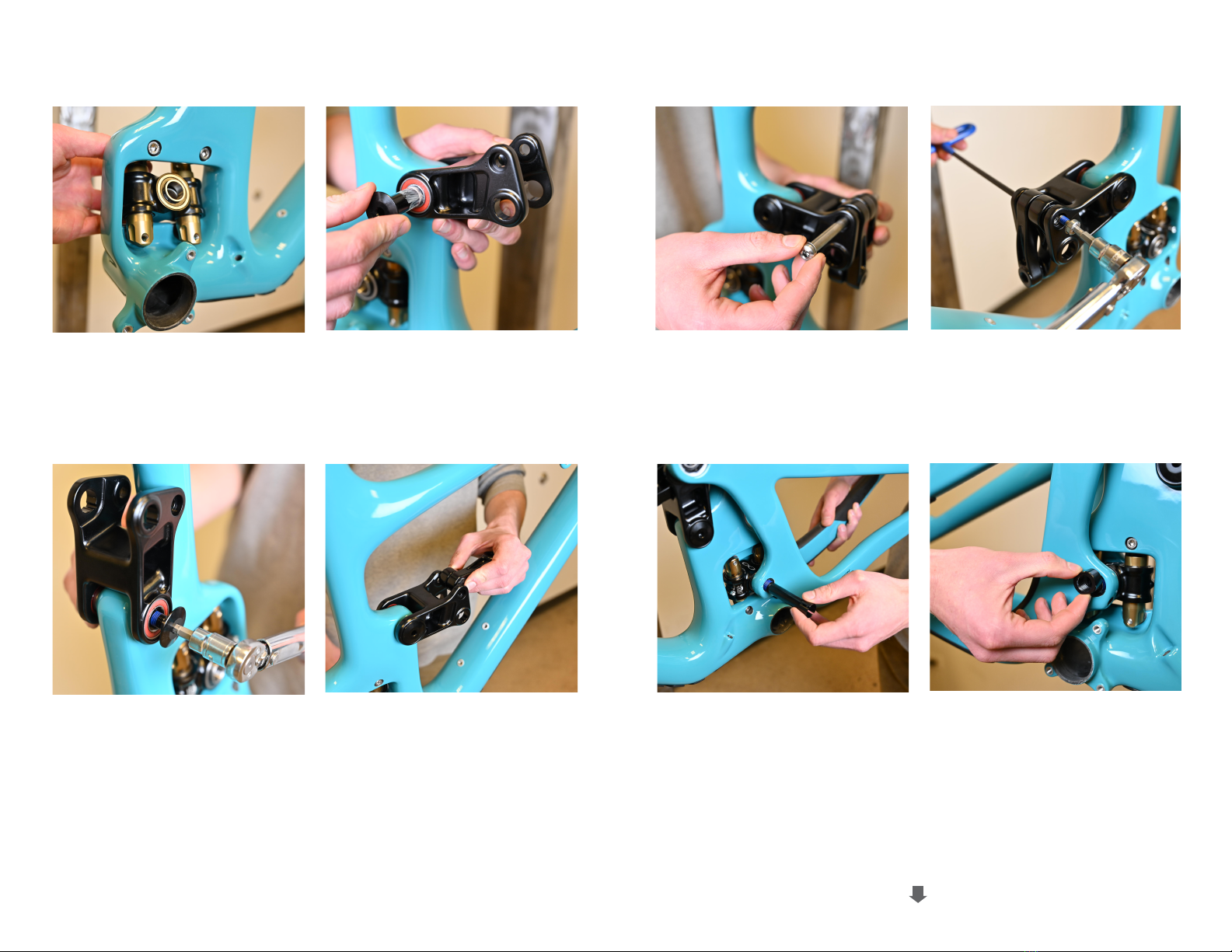

This manual outlines basic setup and

maintenance recommendations of your new

Yeti. Because it is impossible to anticipate

every situation or condition that may occur

during the assembly, setup, and

maintenance of your bicycle, Yeti

recommends that all service and repairs be

performed by your local authorized Yeti

Dealer.

This manual contains many “Warnings” and

“Cautions” concerning the consequences of

failure to maintain or inspect your bicycle.

The word “Warning” indicates a potentially

hazardous situation in which , if not

avoided, could result in serious injury or

death. The word “Caution” indicates a

potentially hazardous situation in which, if

not avoided may result in minor injuries or

damage to your bicycle or a component of

your bicycle. Be sure to read and

understand all of the Warnings and

Cautions listed in the manual.

Warning: Make sure you review and understand the warnings, instructions, and content of this manual and accompanying

manuals for your bicycle.

Warning: Technological advances have made bicycles and bicycle components more complex and the pace of innovation

is increasing. It is impossible for this manual or the accompanying manuals to provide all the information required to

properly repair and/or maintain your bicycle. In order to help minimize the chances of an injury, it is critical for you to have

work performed by an authorized Yeti retailer.