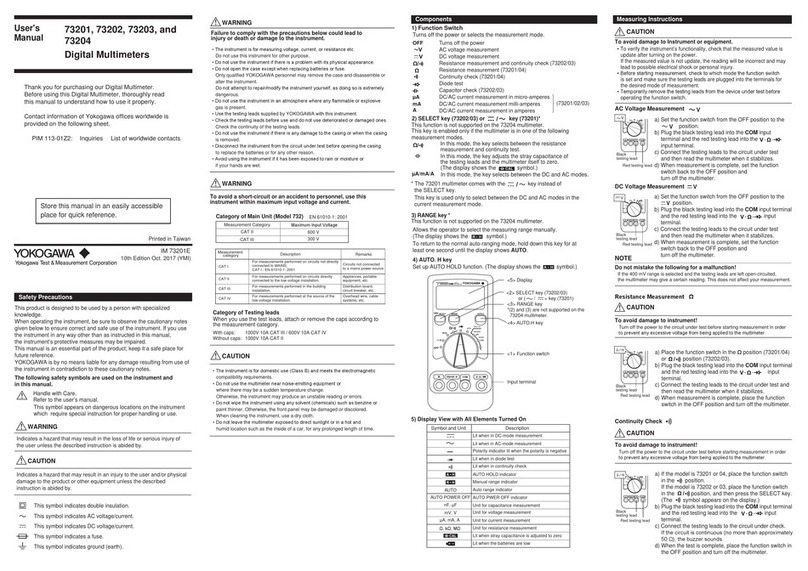

[䉭] key

[䉮] key

This Quick Manual briefly explains the operation,

calibration and routine maintenance of the EXA Series

SC100 Converter and the dedicated conductivity sensor,

SC10XB. Please read the appropriate user's manuals

thoroughly before using this system.

References: User's Manuals

SC100 Panel Mount Conductivity Converter:

IM 12D11A01-01E

SC10XB Conductivity Sensor:

IM 12D11C01-01E

1. Key Operations

• To cancel the operation: Simultaneously press [䉭] and

[䉮] keys.

• To move from measurement display to setup display :

Hold down [ENT] key for at least 3 sec.

• To move from measurement display to calibration display :

Hold down [䉮] key for at least 3 sec.

• To move from setup/calibration display to measurement

display :

Hold down [䉭] key for at least 3 sec.

Main functions of keys

[ENT] key : Confirms the status or setting.

[䉭] key: Moves up a menu item or increases the setting.

[䉮] key: Moves down a menu item or decreases the setting.

2. Start-up

For start-up instructions, refer to the SC100 Panel Mount

Conductivity Converter's User's Manual, IM 12D11A01-01E.

3. Calibration

(Using Standard Calibration Solution)

Refer to Chapter 6 of the SC100 Panel Mount Converter's

User's Manual, IM 12D11A01-01E.

SC100 Panel Mount Conductivity Measurement System

[Quick Manual]

Status Display

• Status of

contact output

(specified by

suffix code)

[ENT] key

Main Display

• Conductivity reading

during measurement

• Setting and data during

calibration/setup

Sub-Display

• Temperature during

measurement

• Parameter during setup

LEDLED NumberAlphabetAlphabet

ZM

YL

XK

9WJ

8VI

7UH

6TG

5SF

4RE

3QD

2PC

1OB

0NA

Display and Operation Keys

Alphanumeric Display Table

IM 12D11A01-11E 1st Edition: Mar. 2003

EXA100 Series

* Conductivity meter does not require calibration using standard solution as routine maintenance if the

correct cell constant has been defined upon start-up.

* For details on the calibration using standard solution, refer to Section 6.5 of the SC100 Panel Mount

Converter's User's Manual, IM 12D11A01-01E.

LED

µS/cm

mS/cm

CANCEL

MEASCALSET

S4

S3

S2

S1

ENT

SC100

EXA

* Calibration should be performed if the cell constant has changed due to prolonged operation.

Press [ENT]

key once.

Water

Calibration

Display Top

Replace the sensor in the process.

Calibration result

is reflected to the

measured value.

Main display stops

flashing and sub-display

is flashing.

Set the conductivity

value of the standard

solution using [䉭] and

[䉮] keys.

Press [䉭] key

for 3 sec.

Measurement

Display

1st digit in Main

display is flashing.

Wait until reading

has stabilized.

Press [䉮] key

for 3 sec.

Measurement

Display

Press [ENT] key twice.

Main and sub displays

flash upon each press.

Rinse the conductivity

sensor well with water

or appropriate solution.

Standard solution

Press [ENT]

key once.

µS/cm

mS/cmmS/cm

EXA SC100

S1

S2

S3

S4

mS/cm

µS/cm

EXA SC100

ENT

S1

S2

S3

S4

SET CAL MEAS

CANCEL

µS/cm

mS/cm

CANCEL

MEASCALSET

S4

S3

S2

S1

ENT

SC100EXA

µS/cm

mS/cm

S4

S3

S2

S1

SC100EXA

Wipe thoroughly after rinse,

and then soak the sensor in

the standard solution.

µS/cm

mS/cmmS/cm

EXA SC100

S1

S2

S3

S4

Decimal point

is flashing.

Move the decimal point

using [䉭] and [䉮] keys.

Press [ENT] key to confirm.

µS/cm

mS/cm

EXA SC100

S1

S2

S3

S4

µS/cm

mS/cm

EXA SC100

S1

S2

S3

S4

µS/cm

mS/cm

EXA SC100

S1

S2

S3

S4

Data updated

µS/cm

mS/cm

S4

S3

S2

S1

SC100EXA

Press [ENT]

key once.

Press [ENT]

key once.