7

IM12B06J02-00EN-P

3. INSTALLATION

3.1.1 P

For accurate pH measurement, a gel

layer must be formed on the mem-

brane surface. For this reason, the

pH-sensitive part of the electrode

should be soaked for 24 hours before

the electrode is used.

When an electrode has been stored

dry, and you need to use it immediately

do so, but as a result, initial regular

calibration will be required until the gel

layer is formed.

The electrode, when dispatched by

Yokogawa, has a protective cover cap

-

brane which ensures you can use the

electrode immediately. Flow electrodes

opening, which is sealed with a cap or

stopper.

NOTE:

Before installation, the above men-

tioned stopper and protective cover

cap must be removed. If required, the

AGC55 may be connected to a reservoir

of electrolyte solution. To maintain a

-

tems, the reservoir must be placed so

that the level of the electrolyte is above

the level of the measuring liquid. Only

under these circumstances will the

correct electrical contact between the

reference system and the measuring

liquid be guaranteed.

3.1.2. M

The combined electrodes must be

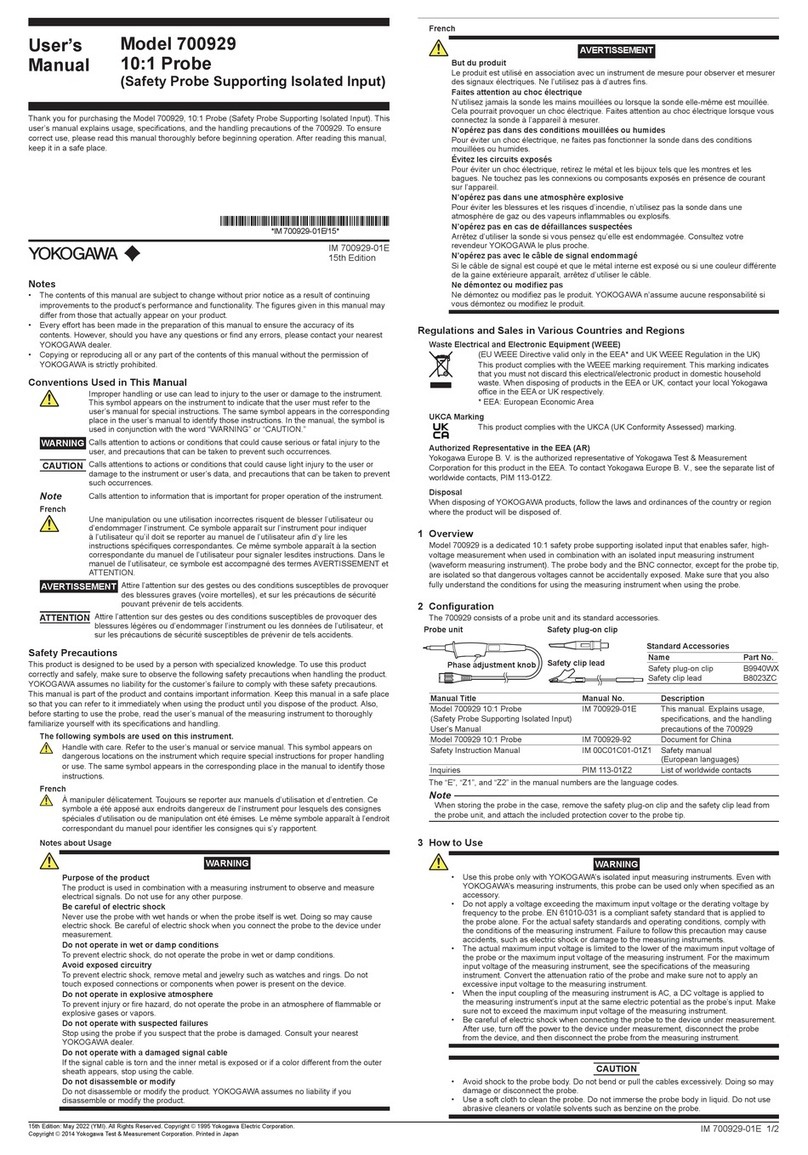

connected with a Coax cable type

WU20-PC, marked with a blue strip. In

areas where electrical interference is

likely, we recommend using the Triax

electrode cable type WU20-LT.. marked

with a blue strip. The cables meet the

requirement of IP65 and can be used

shown in Fig. 1.

The Yokogawa nut can be ordered under

part number: K1500DW.

RESERVOIR FOR SC21C-AGC55

The reservoir, including the connection

kit and tubing, can be ordered sepa-

rately. The connection of the tubing to

the sensor is described in Fig. 5. At the

reservoir side, Yokogawa provides a so

called swagelock connection.

NOTE: Avoid air bubbles in the tubing.

3.2.1 P

After removing the dust cap from the

connector and the protective cover from

the measuring part, the electrode is

ready for use.

NOTE:

For accurate measurements with a Re-

dox/glass electrode, a gel layer must be

formed on the glass membrane surface.

For this reason, the membrane should

be soaked for 24 hours before the

electrode is used. When an electrode has

been stored dry, and you need to use it

-

-

quent re-calibration will be required until

the gel layer is formed. The electrode,

when despatched, has a protective cover

glass membrane which ensures you can

use the electrode immediately.

3.2.2 Mounting

The mounting of the combined Redox/

carried out, as shown in the following

into a PG13.5 process connection. The

3 - 4 on the next page.

Fig. 1. Yokogawa connec-