YOKOGAWA DOX10 User manual

User's

Manual

IM 12J05S01-01E

Model DOX10

Power Supply Unit

IM 12J05S01-01E

1st Edition

i

IM 12J05S01-01E

Introduction

Media No. IM 12J05S01-01E

1st Edition: Feb. 2012 (YK)

All Rights Reserved, Copyright © 2012, Yokogawa Electric Corporation

Introduction

The DOX10 power supply unit feeds power to the DO70G optical dissolved oxygen

sensor and the DO402G dissolved oxygen converter.

This unit can be installed outdoors.

Please read this document thoroughly before use to avoid damage, failure, or improper

operation of the unit.

Throughout this document, important handling instructions are indicated by Warning or

Caution depending on their importance. To ensure safety and prevent damage, users

must follow these instructions.

1. Confirming the Specifications

Make sure that the unit is exactly as ordered. A conduit adapter to protect cables is

included if ordered as an option.

2. Information Described in This Manual

This manual describes information on the specifications, installation, and wiring of the

DOX10.

For information on wiring to DO402G, refer to IM 12J05D02-01E.

The table below shows the instruction manuals of the relevant equipment used in the

dissolved oxygen measuring system.

Table: Manuals of Relevant Equipment Used in Dissolved Oxygen Measuring

System

Model Title of Manual Manual No.

DO402G

DO70G

DOX10

PB350G

PB360G

DOX8HS

PH8PU1

Dissolved Oxygen Converter

Optical Dissolved Oxygen Sensor

Power Supply Unit

Angled Floating Ball Holder

Vertical Floating Ball Holder

Submersion Type Holder

Cleaning Pump/Tank

IM 12J05D02-01E

IM 12J05D04-01E

IM 12J05S01-01E

IM 19H1E1-01E

IM 19H1E2-01E

IM 19H1D2-01E

IM 19C1E1-01E

Note: The manuals in the table are only for the basic components

of the system.

For information on recorders, annunciators and other auxiliary

instruments, refer to respective instruction manuals.

IM 12J05S01-01E

ii

Introduction

For the safe use of this equipment

(1) About This Manual •This manual should be passed on to the end user.

•The contents of this manual are subject to change without prior notice.

•The contents of this manual shall not be reproduced or copied, in part or in whole,

without permission.

•This manual explains the functions contained in this product, but does not warrant

that they are suitable for the particular purpose of the user.

•Every effort has been made to ensure accuracy in the preparation of this manual.

However, when you realize mistaken expressions or omissions, please contact the

nearest Yokogawa Electric representative or sales office.

•This manual does not cover the special specifications. This manual may be left

unchanged on any change of specification, construction or parts when the change

does not affect the functions or performance of the product.

•If the product is not used in a manner specified in this manual, the safety of this

product may be impaired.

(2) Safety and Modification Precautions

•Follow the safety precautions in this manual when using the product to ensure

protection and safety of the human body, the product and the system containing the

product.

(3) The following safety symbols are used on the product as well as in this manual.

DANGER

This symbol indicates that an operator must follow the instructions laid out in this

manual in order to avoid the risks, for the human body, of injury, electric shock, or

fatalities. The manual describes what special care the operator must take to avoid such

risks.

WARNING

This symbol indicates that the operator must refer to the instructions in this manual in

order to prevent the instrument (hardware) or software from being damaged, or a system

failure from occurring.

CAUTION

This symbol gives information essential for understanding the operations and functions.

TIP

This symbol gives information that complements the current topic.

See Also

This symbol identifies a source to be referred to.

This symbol indicates Protective Ground Terminal

This symbol indicates Function Ground Terminal (Do not use this terminal as

the protective ground terminal).

This symbol indicates Alternating current

iii

IM 12J05S01-01E

Introduction

After-Sales Warranty

●Do not modify the product.

●During the warranty period, for repair under warranty carry or send the product to the

local sales representative or service office. Yokogawa will replace or repair any

damaged parts and return the product to you.

●Before returning a product for repair under warranty, provide us with the model name

and serial number and a description of the problem. Any diagrams or data explaining

the problem would also be appreciated.

●If we replace the product with a new one, we won't provide you with a repair report.

●Yokogawa warrants the product for the period stated in the pre-purchase quotation.

Yokogawa shall conduct defined warranty service based on its standard. When the

customer site is located outside of the service area, a fee for dispatching the mainte-

nance engineer will be charged to the customer.

●In the following cases, customer will be charged repair fee regardless of warranty

period.

•Failure of components which are out of scope of warranty stated in instruction

manual.

•Failure caused by usage of software, hardware or auxiliary equipment, which

Yokogawa did not supply.

•Failure due to improper or insufficient maintenance by user.

•Failure due to misoperation, misuse or modification which Yokogawa does not

authorize.

•Failure due to power supply (voltage, frequency) being outside specifications or

abnormal.

•Failure caused by any usage out of scope of recommended usage.

•Any damage from fire, earthquake, a storms and floods, lightning, disturbances,

riots, warfare, radiation, and other natural changes.

●Yokogawa does not warrant conformance with the specific application at the user

site. Yokogawa will not bear direct / indirect responsibility for damage due to a

specific application.

●Yokogawa will not bear responsibility when the user configures the product into

systems or resells the product.

●Maintenance service and supplying repair parts will be covered for five years after

the production ends. For repair this product, please contact the nearest sales office

described in this instruction manual.

IM 12J05S01-01E

iv

Introduction

IM 12J05S01-01E

Contents

Introduction..................................................................................................................... i

For the safe use of this equipment ............................................................................... ii

After-Sales Warranty ................................................................................................... iii

1. Overview ....................................................................................................................... 1-1

1.1 Standard Specifications ................................................................................... 1-1

1.2 Model and Suffix Codes ................................................................................. 1-1

1.3 External Dimensions ....................................................................................... 1-2

2. Installation and Wiring ............................................................................................... 2-1

2.1 Installation ....................................................................................................... 2-1

2.1.1 Installation Location ................................................................................ 2-1

2.1.2 How to Mount It...................................................................................... 2-1

2.2 Wiring.............................................................................................................. 2-2

2.2.1 Connecting Sensor Cable ........................................................................ 2-3

3. Inspection and Maintenance.......................................................................................3-1

3.1 Power Supply Unit Inspection ........................................................................ 3-1

3.1.1 Checking for Moisture and Performing the Required Maintenance ...... 3-1

3.1.2 Checking for Corrosion and Performing the Required Maintenance..... 3-1

Customer Maintenance Parts List .................................................. CMPL 12J05S01-01E

Revision Record .................................................................................................................... i

IM 12J05S01-01E

IM 12J05S01-01E 1-1

1. Overview

1. Overview

The DOX10 power supply unit feeds power to the DO70G optical dissolved oxygen

sensor and the DO402G dissolved oxygen converter.

1.1 Standard Specifications

Construction : JIS waterproof (IP 53)

Case material : Fiberglass reinforced polycarbonate resin.

Case Color : Grayish-green (Munsell 2.5G5.0/1.0)

Mounting : Bracket mounting (mounting bracket unnecessary)

Pipe mounting (need to specify pipe mounting bracket)

Wall mounting (need to specify wall mounting bracket)

Electrical connections :Watertight plastic gland with cable. (applicable cable O.D. : 6 to 12)

Conduit adaptor (optional available)

Ambient temperature :-10 to 55ºC

Humidity range : 10 to 90% RH (non-condensing)

Power supply : 100/115/230V AC 50/60Hz

Acceptable range : Rated Voltage ±15%

Output voltage : 24V DC ±1V

Terminal : M4 screw

Weight : Body ; Approx. 1.6 kg

Mounting bracket ; Approx. 0.7 kg

Attached cable ; Approx. 0.3 kg

1.2 Model and Suffix Codes

DOX10 power supply unit

Power supply

Cable length -00

-15 -N

Option Mounting bracket

Tag plate

Conduit work adaptor

/P

/W

/SCT

/CB1

/CD1

/CF1

Pipe mounting bracket

Wall mounting bracket

Stainless steel tag plate

G1/2, 1pcs

1/2 NPT, 1pcs

M20 1.5, 1pcs

T0101.eps

Model Suffix Code

Option

Code

Specifications

DOX10 -U Power supply Unit

Always -U

No cable

1.5m (DO402G power supply use)

Always -N

(*) In case of conduit construction, adaptor for conduit construction is specified.

IM 12J05S01-01E

1-2

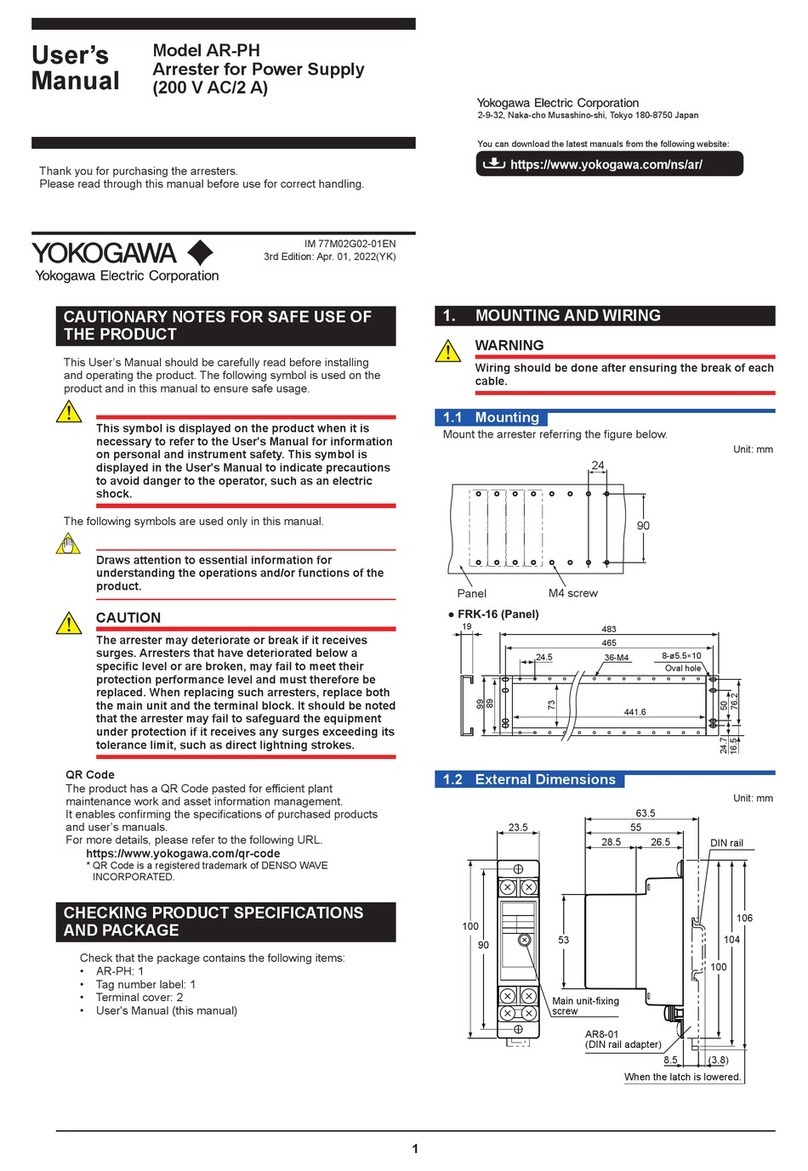

1.3 External Dimensions

DOX10 power supply unit

F15.EPS

(b) Watertight plastic cable gland

with conduit adaptor

Approx. 26

Please use the watertight cable gland of the attachment.

If metallic conduit is directly connected with the case,

it becomes the factor of the measurement error

17

75±0.2

76

76

70±0.2

36

10

275

203

Sensor cable inlet

Converter cable inlet

Power cable inlet

4-M5 screws, (depth:10mm)

(a) Watertight plastic cable gland (St'd)

(for mounting)

Adaptor

49

Approx. 55

Adaptor for Conduit

Weight:Approx. 1.6kg

G1/2 female (/CB1)

1/2 NPT female (/CD1)

M201.5 (CF1)

Attached cable with DOX10 (Not supplied if suffix code "-00-N" is selected)

Cable length :1.5 m

G

N

L

G

N

L

Black L

White N

Red G

White N

Black L

Red G

80

50

Model and Suffix Code

Approx. 1,500DOX10 - U - 15 - N

DOX10 - U - 00 - N No cable

Weight :Approx. 0.3kg (1,500mm)

L (mm)

Unit : mm

IM 12J05S01-01E 1-3

1. Overview

Pipe mounting bracket for power supply unit (optional)

(option code: /P)

Nominal 50A

U-bolt

4-M5 screw

10 90 56

Pipi mounting bracket 2

Pipe mounting bracket 1

200±0.5

100

70

353515 75 8

70 5- 6.5 holes

6.513 hole

2- 9±0.5 holes

4- 10 holes

Weight: 0.7 kg

Unit : mm

(O.D. 60.5 pipe)

M8 nut 2

2- 5.5 holes

Wall mounting bracket for power supply unit (optional)

(option code: /W)

Wall mounting bracket

70

875

15 35 35

70

100

200 ±0.5

4-M5 screw

4-M6 screw

10 90 15

Weight: 0.7 kg

Unit : mm

5- 6.5 holes

2- 5.5 holes

4- 10 holes

6.5 13 hole

IM 12J05S01-01E

1-4

IM 12J05S01-01E 2-1

2. Installation and Wiring

2. Installation and Wiring

2.1 Installation

2.1.1 Installation Location

Since power supply unit is waterproof, you can install it outdoors. Be sure to install it

as close to the converter as possible.

Note:

Avoid installing the unit in ambient air containing excessive moisture or corrosive gas.

If the case cover is not closed tightly in excessive moisture or corrosive gas, the unit

may suffer problems such as insulation failure, disconnection, or poor contact.

2.1.2 How to Mount

Power supply unit can be mounted on bracket, pipe (nominal 50A size) or wall. How-

ever for pipe or wall mounting, order and use the optional mounting bracket. This

mounting bracket is supplied when specified.

Nominal 50A

U-bolt

4-M5 screw

10 90 56

Pipi mounting bracket 2

Pipe mounting bracket 1

200±0.5

100

70

353515 75 8

70 5- 6.5 holes

6.513 hole

2- 9±0.5 holes

4- 10 holes

Weight: 0.7 kg

Unit : mm

(O.D. 60.5 pipe)

M8 nut 2

2- 5.5 holes

Figure 2.1 Pipe Mounting

Wall mounting bracket

70

875

15 35 35

70

100

200 ±0.5

4-M5 screw

4-M8 screw

10 90 15

Weight: 0.7 kg

Unit : mm

5- 6.5 holes

2- 5.5 holes

4- 10 holes

6.5 13 hole

Figure 2.2 Wall Mounting

IM 12J05S01-01E

2-2

2.2 Wiring

Indoors terminal board in power supply unit is connected by dedicated sensor cable

(used for wiring sensor to the DO402G).

CAUTION

When connecting the sensor to the terminals, match the colors, symbols, and numbers

described in the wiring diagram (it is packaged with the sensor cable).

K9679HA

(DOX10 attached cable)

11

Clear

Red

BROWN BLUE

White

Green

Green/Yellow

18

17

14

12

G

N

L

LNGLNG -

BLUE

+

BROWN

DO402G (Converter)

DO70G

AC IN TO CONVERTER

DOX10 (Power Supply Unit)

Attached cable with DOX10 (Not supplied if suffix code "-00-N" is selected)

Cable length :1.5 m

G

N

L

G

N

L

Black L

White N

Red G

White N

Black L

Red G

80

50

Model and Suffix Code

Approx. 1,500DOX10 - U - 15 - N

DOX10 - U - 00 - N No cable

Weight : Approx. 0.3kg (1,500mm)

L (mm)

Figure 2.3 Attached Cable

IM 12J05S01-01E 2-3

2. Installation and Wiring

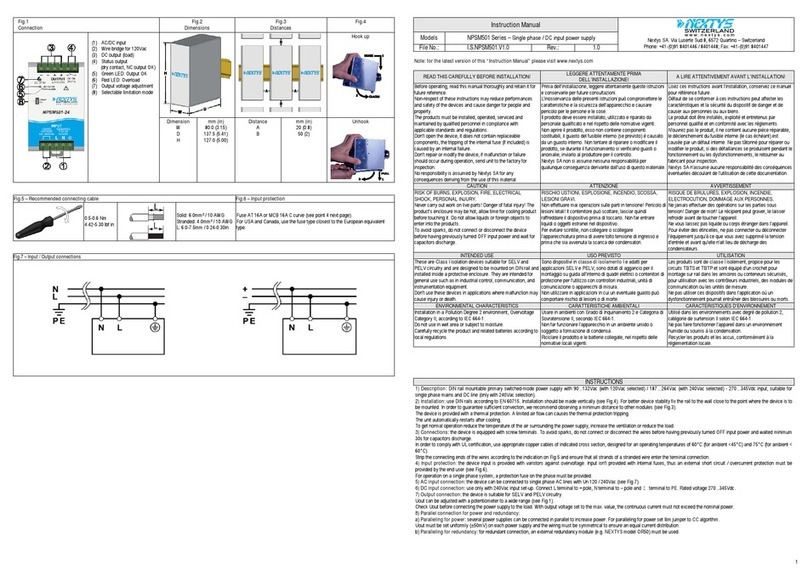

2.2.1 Connecting Sensor Cable

(1) Loosen two screws which are at front of power supply unit and detach the cover.

(2) Pull the cable into the power supply unit from sensor cable inlet hole.

(3) Connect the sensor cable to the terminals.

After passing the cable through the nut, check the color on each core wire, then

connect each core wire to the corresponding terminal.

DO70G Wiring Diagram Example

DO402G DOX10

Detail-1

Detail-2

DO70G

Detail-1(DO402G)

Detail-2(DOX10)

(Wiring color)

DO70G Red

Clear

Green/Yellow

Green

White

DO402G (Terminal No.)

18

17

14

12

11

BROWN

BLUE

(Wiring color)

DO70G + BROWN

- BLUE

DOX10 (Terminal No.)

K9679AX

Connections of the sensor cable and DO402G terminals

are shown in the following table.

Connections of the sensor cable and DOX10 terminals

are shown in the following table.

Figure 2.4 Connecting Sensor Cable

(4) Mount the cable gland in the cable inlet hole.

Put the nut in place, and screw it onto the main body sufficiently. At this time,

loosen the packing gland so that the cable is not twisted. After fixing the main body,

tighten the packing gland to keep moisture out of the equipment. However if the

packing gland is screwed up too tight, the cable will be damaged.

IM 12J05S01-01E

2-4

IM 12J05S01-01E 3-1

3. Inspection and Maintenance

3. Inspection and Maintenance

Normally, it is sufficient to inspect the DOX10 power supply unit during periodic

system repairs (once a year or every two years), as fan as it works without fail. Daily

inspection and maintenance are not required.

3.1 Power Supply Unit Inspection

3.1.1 Checking for Moisture and Performing the Required Maintenance

Remove the cover of the terminal box and check for moisture. If the inside is very

damp, use a hair drier to dry the inside of the box.

3.1.2 Checking for Corrosion and Performing the Required Maintenance

Check that corrosive gas has not entered the terminal box and corroded the terminals

and conductors. If the corrosion is excessive and problems such as poor contact and

disconnection seem likely, replace the corroded apparatus.

IM 12J05S01-01E

3-2

Customer

Maintenance

Parts List

All Rights Reserved, Copyright © 2012, Yokogawa Electric Corporation.

Subject to change without notice.

DOX10

Power Supply Unit

CMPL 12J05S01-01E

87

6

5

4321

9

10

11

12

Item Part No. Qty Description

1 K9141LA 1 Case

2 K9679FG 1 PlateAssy.

3 Y9408LU 4 Screw

4 K9141MB 1 Gasket

5 G9303NB 1 O-ring

6 K9141LD 1 Case

7 G9303NF 2 O-ring

8 K9141MH 2 Screw

9 L9811FM 3 Nut

10 L9811FN 3 Gasket

11 L9811FE 3 Body

12 A1630UP 1 Power Unit

1st Edition : Jan,2012

Revision Record

Manual Title : Model DOX10 Power Supply Unit

Manual Number : IM 12J05S01-01E

Edition Date Remark (s)

1st Feb. 2012 Newly publishd

This manual suits for next models

2

Table of contents

Other YOKOGAWA Power Supply manuals