2

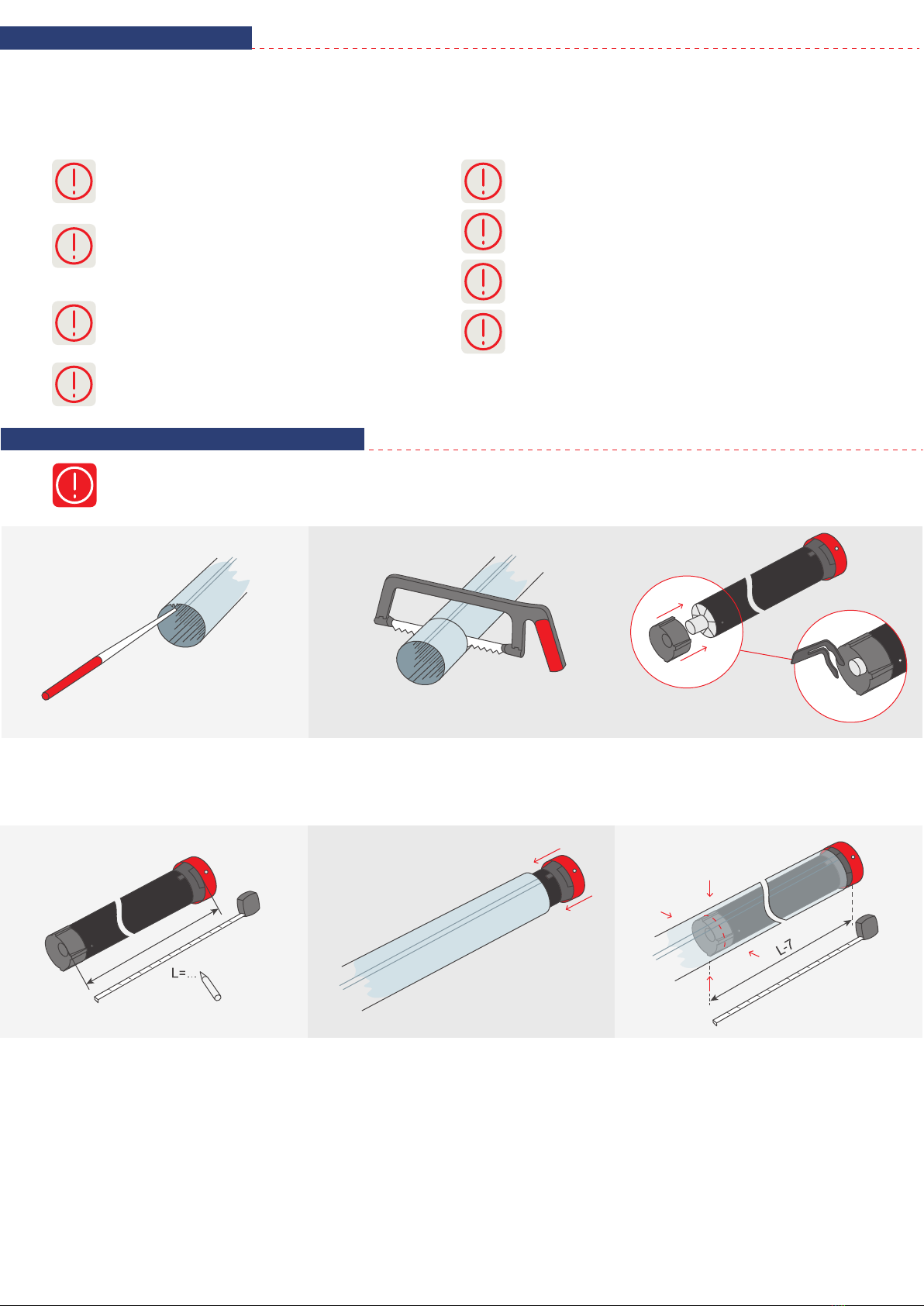

2. Safety measures

Before installing or using motor please read the following instruction. The installer must comply with the standards and regulations in

force in the country where the appliance will be installed and provide information to users about the conditions and maintenance of the

device. Failure to follow these instructions can present risk to life and health, or invalid functioning of the roller shutter. This also results

in the loss of warranty rights.

Motors torque parameter should be adequate

to the weight of the roller shutter curtain.

Wiring should be mounted in a way preventing

water from entering the tubular motor, as well

as for moving roller shutter curtain to make

any damage

Electrical system control should be performed

regularly to detect any signs of use or damage

of the motor.

Electrical supply needs to be disconnected

before conducting any maintenance,

cleaning and/or repair work.

All contact of the motor with any liquids

should be reduced to minimum.

No tools should be used when

placing motor in the tube.

During the adapter montage special attention

must be paid not to damage the motor.

Motor and its control system should

be kept out of children reach.

1. Motor should be mounted in places protected from unfavourable weather conditions.

2. For proper operation of the motor, it is necessary to use block hangers.

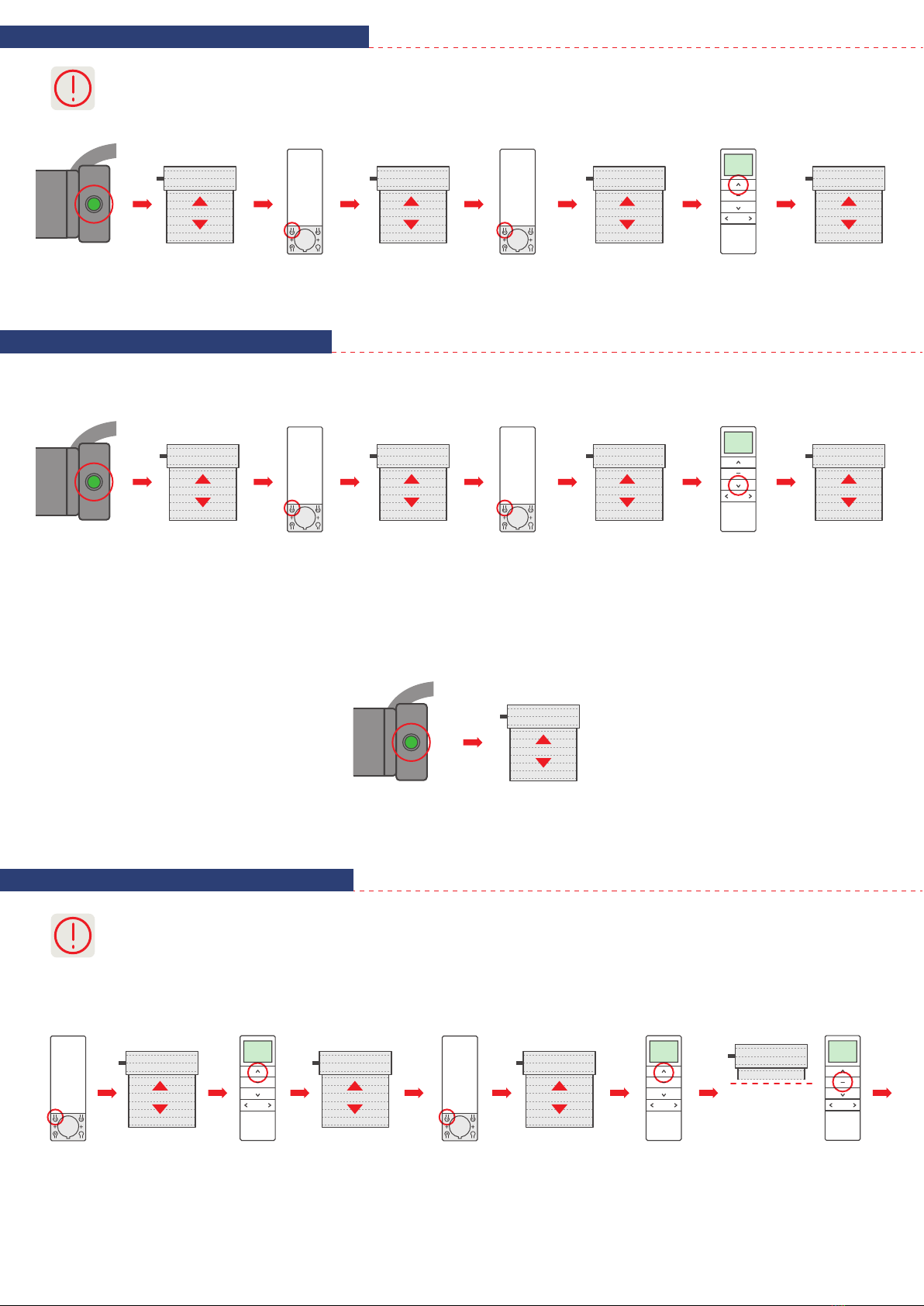

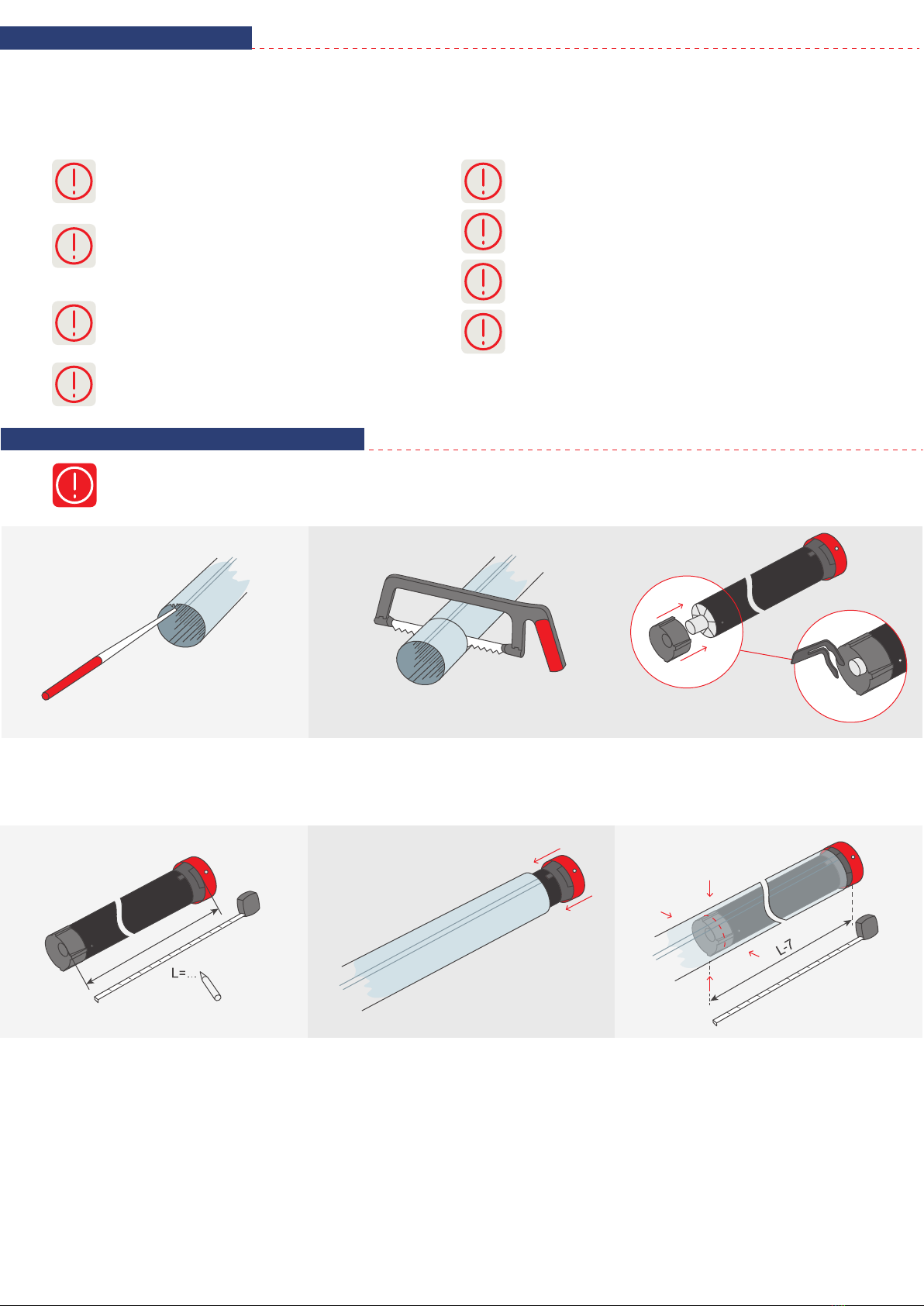

3. Placing motor in the tube

2. Cut the tube to the proper length.1. Deburr the edges

and remove the metal residue.

3. Place the adaptation

on the motor.

4. Measure the distance (L)

between the inner edge of motors head

and the end of the motors adaptor.

5. Insert the motor into the tube

up to the point of connection

between the edge of the tube and

the inner edge of the motors head.

6. Secure the tube to the coupling

part of the adaptation using

4 screws or rivets, placed at L-7 mm

distance from the inner edge of the

motors head.