036-21300-002-A-0905

2Unitary Products Group

TABLE OF CONTENTS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ACCESSORIES—FIELD INSTALLED . . . . . . . . . . . . . . . .1

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

APPLICATION FLEXIBILITY . . . . . . . . . . . . . . . . . . . . . . .3

LIST OF FIGURES

Fig. # Pg. #

1 VERTICAL AND HORIZONTAL APPLICATION

KEU060, 090 & 120 . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 VERTICAL AND HORIZONTAL APPLICATION

KEU180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 SUSPENSION MOUNTING (HORIZONTAL) -

KEU060, 090 AND 120 . . . . . . . . . . . . . . . . . . . . . . . .5

4 SUSPENSION ACCESSORY (HORIZONTAL) -

KEU180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5 UNIT DIMENSIONS KEU060 . . . . . . . . . . . . . . . . . .16

6 UNIT DIMENSIONS KEU090 & 120 . . . . . . . . . . . . .17

7 UNIT DIMENSIONS KEU180 . . . . . . . . . . . . . . . . . .18

8 ACCESSORY DIMENSIONS . . . . . . . . . . . . . . . . . .19

9 RETURN AIR GRILL . . . . . . . . . . . . . . . . . . . . . . . . .20

10 BASE ACCESSORY . . . . . . . . . . . . . . . . . . . . . . . . .20

11 STEAM COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

12 HOT WATER COIL . . . . . . . . . . . . . . . . . . . . . . . . . .21

13 FIELD WIRING FOR POWER SUPPLY . . . . . . . . . .24

14 COOLING ONLY UNIT . . . . . . . . . . . . . . . . . . . . . . .24

15 UNIT WITH STEAM OR HOT WATER COIL

ACCESSORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

16 FIELD WIRING FOR UNITS WITH ELECTRIC

HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

LIST OF TABLES

Tbl. # Pg. #

1 UNIT SUSPENSION MOUNTING (HORIZONTAL

APPLICATION) WEIGHTS . . . . . . . . . . . . . . . . . . . . . 5

2 KEU OPERATING WEIGHTS (LBS.) . . . . . . . . . . . . . 5

3 SOUND POWER RATINGS . . . . . . . . . . . . . . . . . . . . 6

4 HEATING CAPACITY - ELECTRIC HEAT

ACCESSORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 STEAM COIL CAPACITY, MBH@2 PSIG . . . . . . . . . 8

6 HOT WATER CAPACITY, MBH . . . . . . . . . . . . . . . . . 8

7 PRESSURE DROP VS. GPM . . . . . . . . . . . . . . . . . . . 8

8 CAPACITY CORRECTION VS. GPM . . . . . . . . . . . . . 8

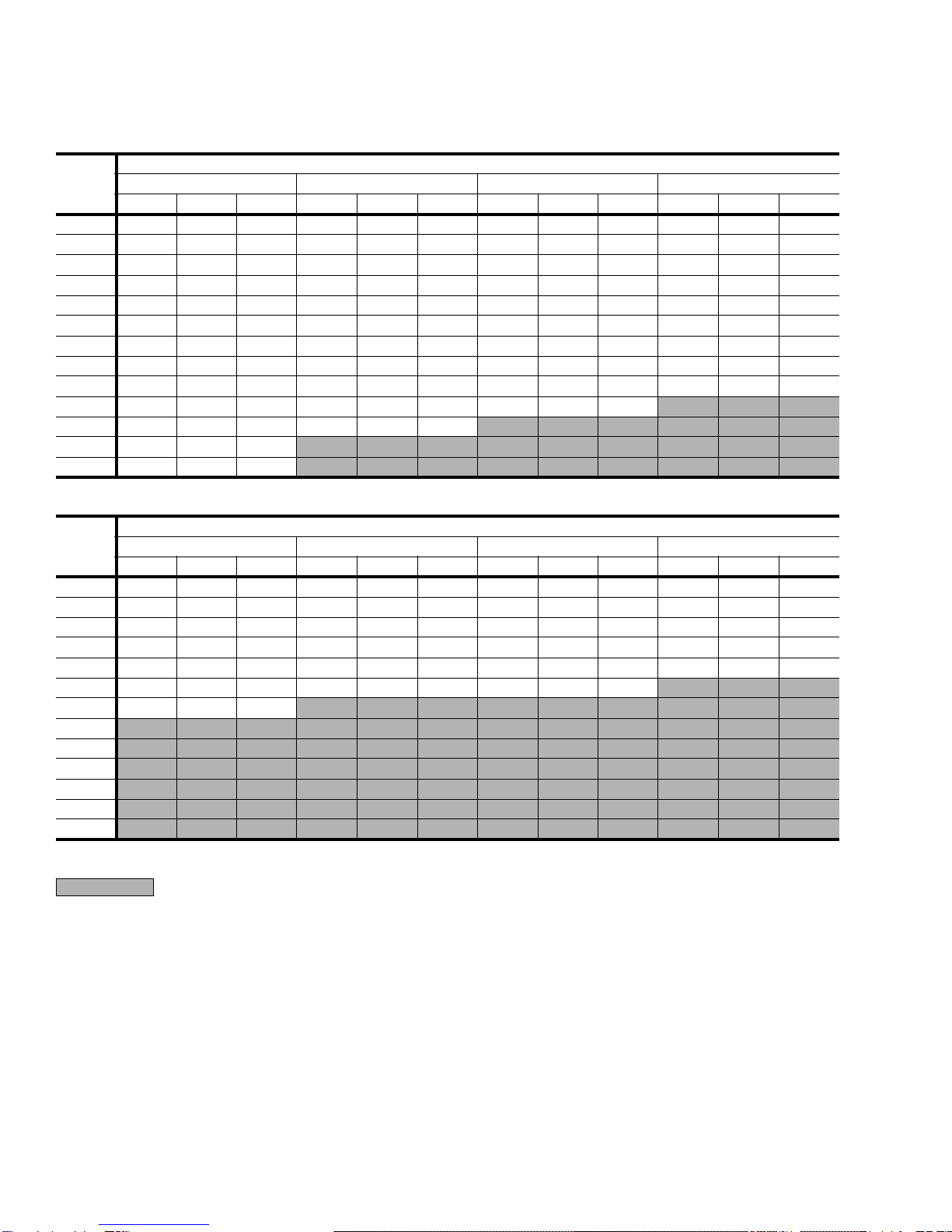

9 SUPPLY AIR BLOWER PERFORMANCE -

KEU060 (5 TON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10 SUPPLY AIR BLOWER PERFORMANCE -

KEU090 (7.5 TON) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

11 SUPPLY AIR BLOWER PERFORMANCE -

KEU120 (10 TON) . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

12 SUPPLY AIR BLOWER PERFORMANCE -

KEU180 (15 TON) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

13 STATIC RESISTANCE FOR UNIT ACCESSORIES

(IWG) - KEU060-120 . . . . . . . . . . . . . . . . . . . . . . . . . 13

14 STATIC RESISTANCE FOR UNIT ACCESSORIES

(IWG) - KEU180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15 SUPPLY AIR PLENUM PERFORMANCE DATA . . . 14

16 BLOWER MOTOR AND DRIVE DATA . . . . . . . . . . . 14

17 KEU PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . 15

18 UNIT CLEARANCES KEU060 . . . . . . . . . . . . . . . . . 16

19 UNIT CLEARANCES KEU090 & 120 . . . . . . . . . . . . 17

20 UNIT CLEARANCES KEU180 . . . . . . . . . . . . . . . . . 18

21 ELECTRIC HEATER DIMENSIONS KEU060, 090,

120 & 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

22 KEU ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . 22