550.13-TG2Y (1001)

Unitary Products Group 3

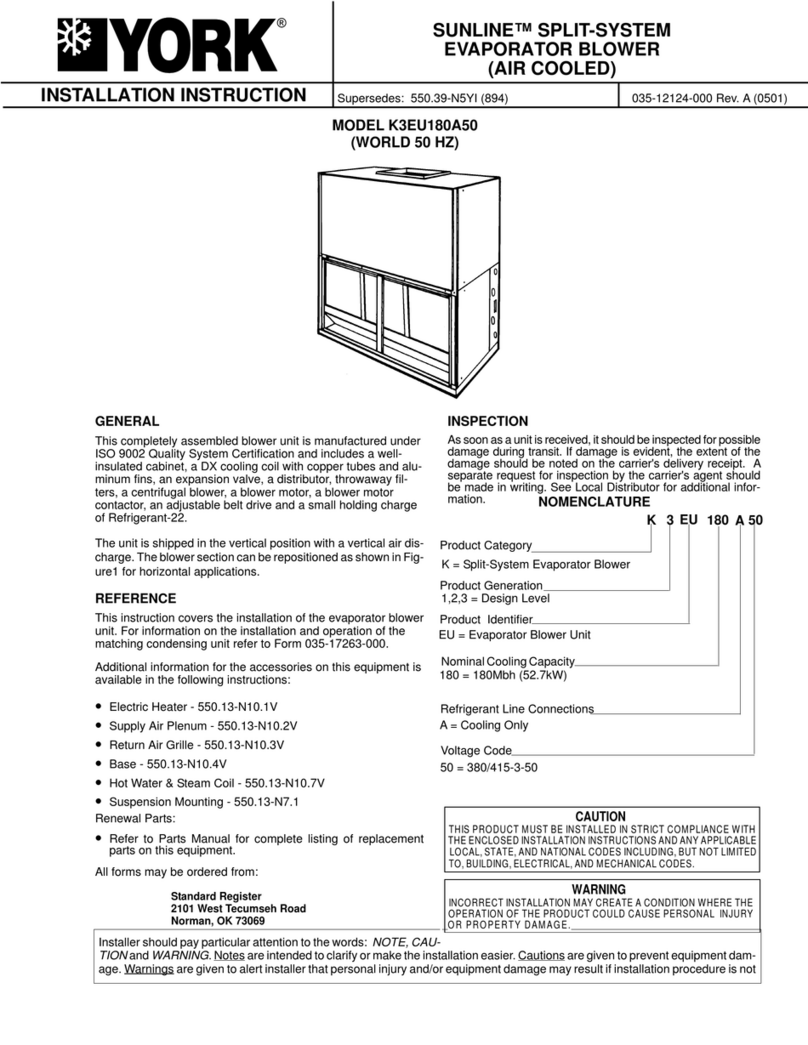

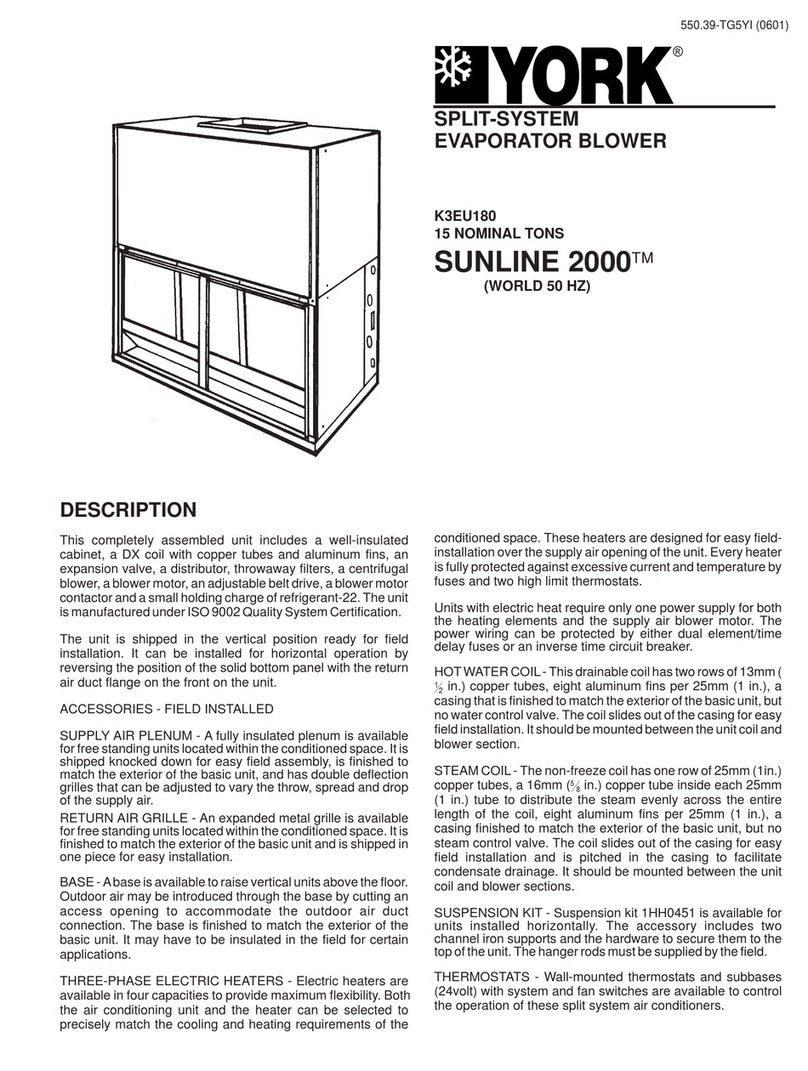

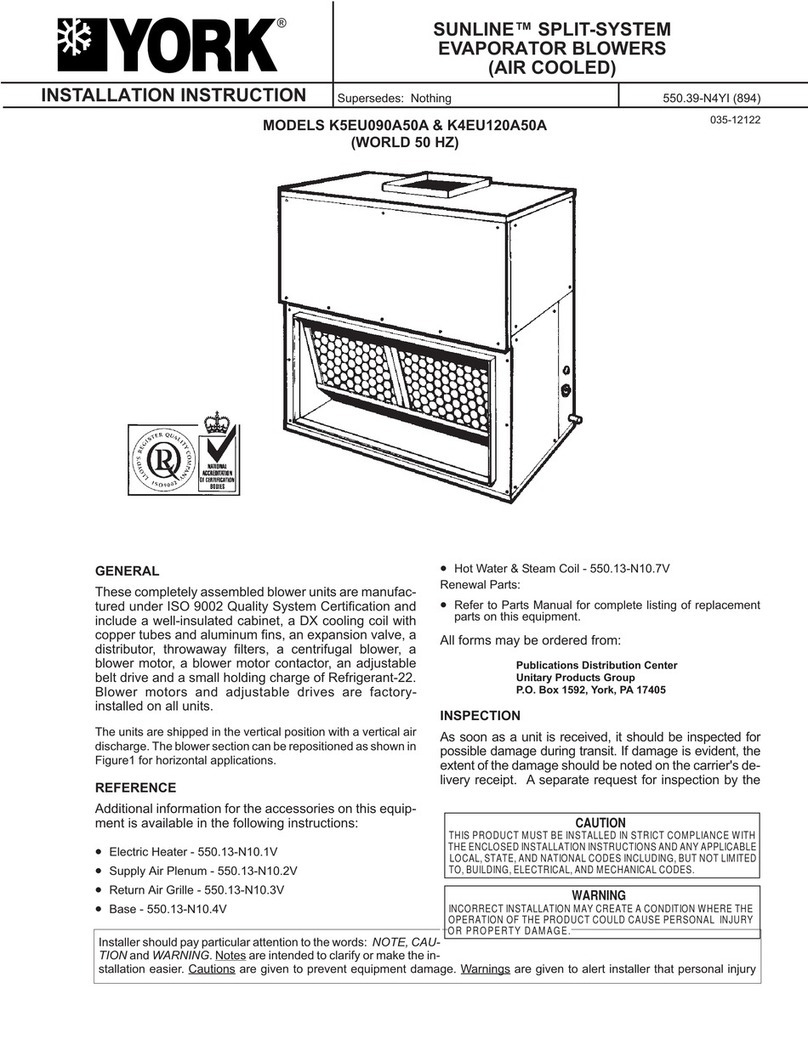

DESCRIPTION

Evaporator blower units are desi

ned with two distinct mod-

ules to provide maximum application flexibilit

. The 30 and 40

ton units are shipped as sin

le packa

es with the blower

module mounted on top of the coil module, The blower mod-

ule can be repositioned in the field to meet almost an

instal-

lation requirement. Blower and coil modules for the 50 ton

units are shipped separatel

to simplif

handlin

. These mod-

ules can be connected in the field with the same flexibilit

as

the smaller units.

The blower module includes the blower wheels and room for

a field-mounted motor and drive. The coil module includes

direct expansion coils, 1 in. throwawa

filters, liquid line sole-

noid valves for both capacit

reduction and pumpdown, ther-

mal expansion valves, distributors and a condensate drain

pan.

Ever

evaporator coil is pressurized with air to 325 psi

and

leak tested under water. After the headers are brazed onto

the coil and the coil is installed in the unit, the coil is pressur-

ized with a combination of refri

erant-22 and nitro

en to 150

psi

for pressure testin

and additional leak testin

. After the

coil is evacuated and deh

drated, it is pressurized with a

holdin

char

e of refri

erant-22 for stora

e and/or shippin

.

Steam coils, hot water coils, base sections, suspension hard-

ware, blower motors and drive packa

es are available as

field-installed accessories to provide additional application

flexibilit

.

These evaporator blowers, combined with condensin

units,

provide

ears of quiet, efficient and dependable operation.

These units are manufactured under ISO 9001 Qualit

S

s-

tem Certification.

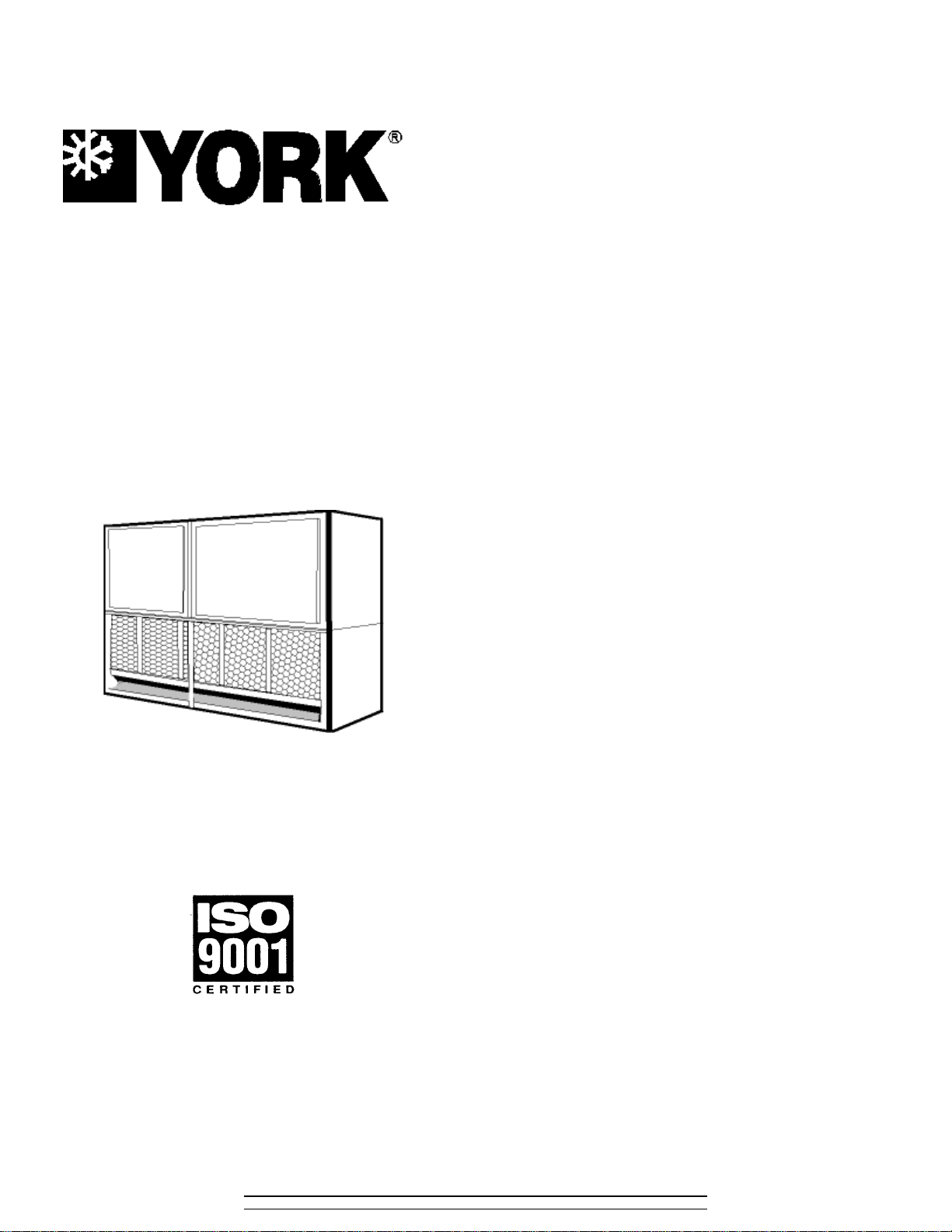

MODULAR DESIGN

These evaporator blowers can be arran

ed for a variet

of air

dischar

e patterns in either the horizontal or the vertical posi-

tion.

The above illustration shows three of the common installation

arran

ements. Refer to the unit installation instructions for

other possibilities.

Units ma

be bottom-supported or ceilin

-suspended and

can be arran

ed to meet almost an

space or duct require-

ments. Each unit is available with a choice of blower motors,

drive packa

es and other accessories to make them suitable

for most applications.

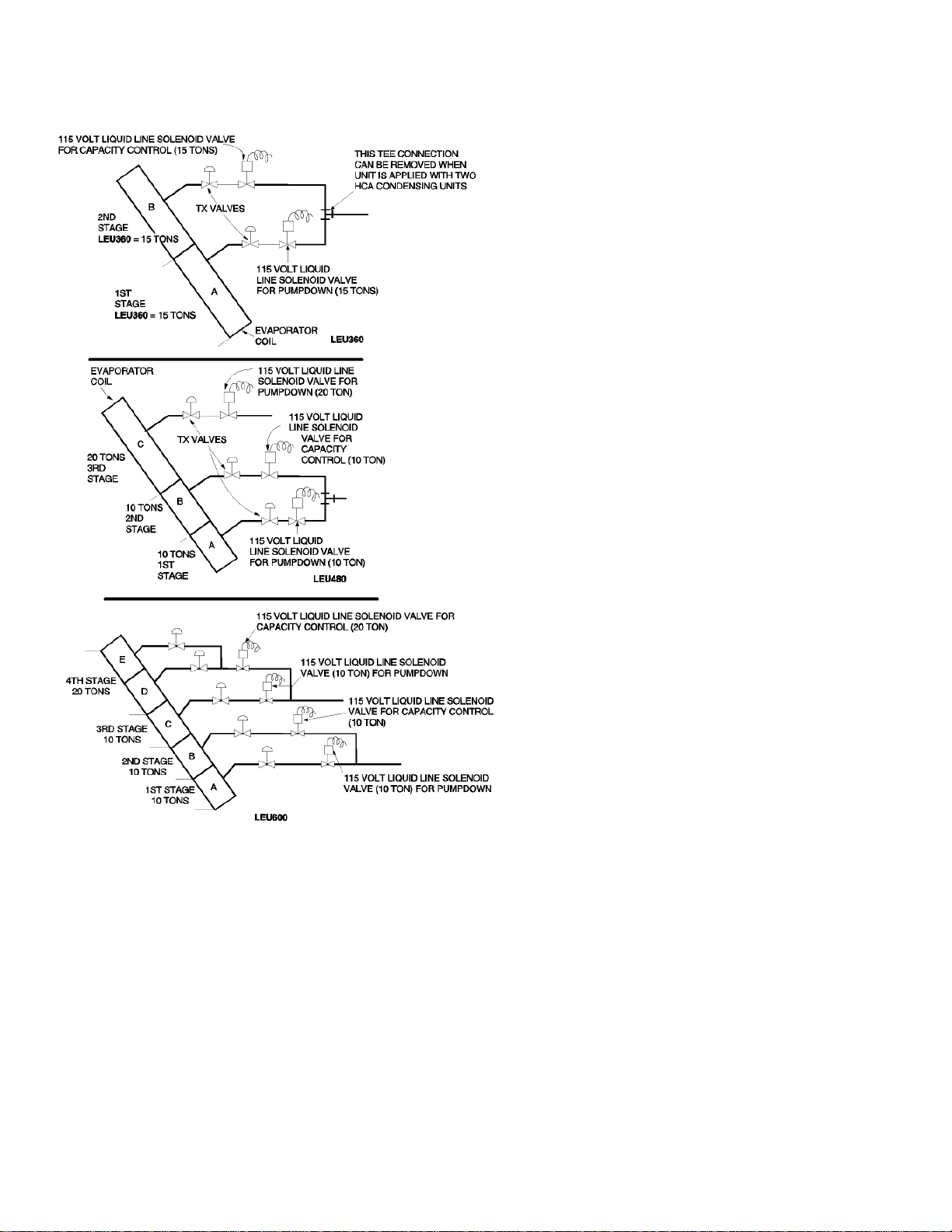

FACTORY-MOUNTED COMPONENTS

PART LOAD OPERATION These evaporator blowers have

multiple coils with pre-piped distributors, expansion valves

and solenoid valves. Field modifications are not required for

part load operations. Capacit

reduction not onl

provides

economical operation, but also maintains more even temper-

ature and humidit

levels in the conditioned space.

EASY SERVICE Serviceable expansion valves are provided

on ever

unit. These superior valves are factor

-installed to

provide man

ears of trouble-free operation. If service is

required, it is not necessar

to unbraze an

joints.

PUMPDOWN Evaporator blowers include a solenoid valve

for non-rec

clin

pumpdown. When the coolin

requirement

in the conditioned space is satisfied, the refri

erant is

pumped into the hi

h side of the s

stem.

ACCESSORIES

BASE SECTIONS (30 and 40 ton onl

) Base sections can

used to elevate units above the floor. If desired, outdoor air

ma

be introduced throu

h these sections b

cuttin

an

access openin

to accommodate the outdoor air duct con-

nection. These bases have a durable finish to match the

evaporator blower unit. The

ma

have to be insulated for

certain applications.

SUSPENSION PACKAGES These accessories can be used

to suspend horizontal units from above without interferin

with access to the unit. The

can also be used for elevatin

a

floor-mounted unit (either horizontal or vertical) to provide

additional hei

ht for the installation of a trap at the conden-

sate drain connection. All suspension packa

es can be used

with vibration isolators.

HOT WATER COILS Drainable water coils are available for

field installation between the blower and the coil modules of

both horizontal and vertical units. Since their casin

s match

the dimensions and the finish of the basic units, the

become

an inte

ral part of the unit after installation. The coils slide out

of their casin

s for eas

installation. Coils have copper tubes

that have been mechanicall

expanded into aluminum fins.

Both headers are located on the same end of the coil. Coils

are leak-tested at 325 psi

under water and dried before their

connections are capped for stora

e and shippin

.

STEAM COILS (LEU360 onl

) A steam coil is available on

the LEU360 for installation between the blower and coil mod-

FIGURE 1 : UNIT INSTALLATION